Autoclave

Compression RTM for production of future aerostructures

Automated preforming and 5-min resin infiltration show a way forward for lower-cost CFRP primary structures.

Read MorePlant Tour: RUAG Space, Decatur, Alabama, U.S.

Out-of-autoclave composites manufacturing facility comes of age with first U.S.-made composite structures for the Atlas V launcher, and qualification parts for the Vulcan.

Read MoreCarbon ThreeSixty invests in Tailored Fiber Placement cell

The U.K.-based structural composites specialist says the automated cell delivers composite products three times faster, with up to 90% waste reduction.

Read MoreThe coming decade: Clarity with a strong dose of uncertainty

Columnist Dale Brosius considers the potential and uncertain role of composites in aerospace, automotive and other markets in the coming decade.

Read MoreTo boldly go . . .

Space travel is a challenge, even if filmmakers like to make us think otherwise.

Read MoreBoeing 777X achieves first successful flight

The 777X jetliner, which features the longest carbon fiber composite aircraft wings yet manufactured, took to the skies for its maiden flight on Jan. 25.

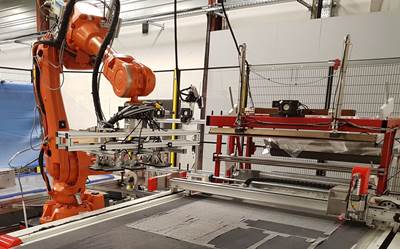

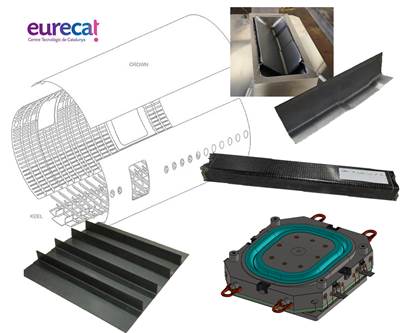

Read MoreAdvancing thermoplastic composites and RTM for Clean Sky 2 in Spain

EURECAT leads projects for TPC keel beam, window frames and thermoset RTM fuselage frames with TPC shear ties for next-gen aircraft.

Read MoreElectric tugs ease loading of aerostructures in and out of autoclave

The MasterMover MT600+ electric tug is said to enable an operator to easily push, pull and steer wheeled loads up to 6,000 kilograms.

Read MoreOne-piece, one-cure, infused carbon fiber wheel is ready to roll

ESE Carbon Co.’s new carbon fiber wheel uses tailored fiber placement and custom presses to minimize waste and improve scalability.

WatchTech Table: Adhesives

A table of aerospace structural adhesives includes collected from data provided by suppliers.

Read More