Autoclave

Fibreworks Composites launches sister firm Composite Factory

Composite Factory will be ISO AS9100-certified and offer build-to-print, quick-turn prototype and pre-production fabrication of composite parts and structures.

Read MoreAscent Aerospace invests in large-format AM machine

The LFAM machine will enable fabrication and delivery of production-ready fixtures and molds at significantly reduced lead-times.

Read MoreComposites suppliers, fabricators respond to coronavirus

Companies across the composites industry supply chain share how the COVID-19 pandemic is affecting their businesses, and how they are available to help.

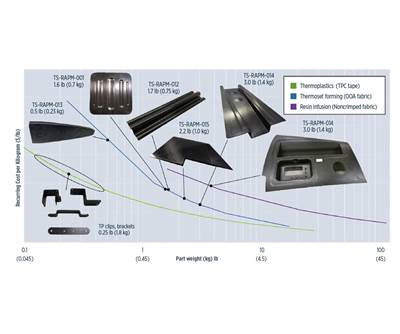

Read MoreRevolutionizing the composites cost paradigm, Part 2: Forming

Boeing-led parts trials explore infusion, compression molding and thermoplastics, offering lessons and supply chain options to better compete with aluminum.

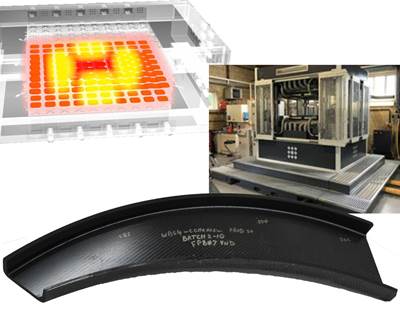

Read MoreRAPM development with PtFS

Boeing-led program explores rapid part cycles using automated, 180-channel thermal control molding cell for infusion, thermoset prepreg and thermoplastic composites.

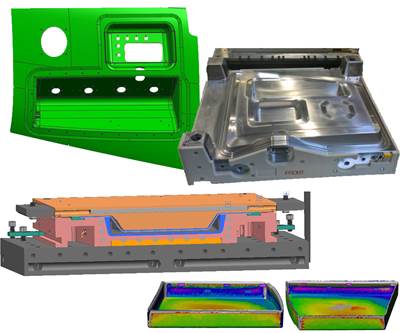

Read MoreManufacturing the complex geometry parts of RAPM

Boeing-led program explores simulation, tooling, preforming and molding approaches to lower composites part cost.

Read MoreNovel prepreg for compression molding in RAPM

Solvay and Boeing combine aerospace performance with process knowledge for high-rate, low-cost composites production.

WatchPark Aerospace Corp. introduces mid-toughened epoxy resin system

The E-752-MTS mid-toughened 350°F (177°C) cure epoxy system is designed for primary and secondary aircraft structure applications.

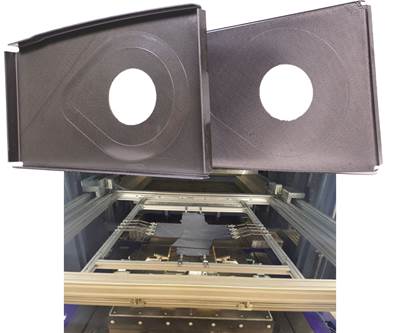

Read MoreCombination of automation, rigid foam core enable high-volume aircraft part production

A feasibility study demonstrates increased production capacity using Evonik foam core and automated manufacturing.

Read MoreHexcel carbon fiber prepreg selected for ultralight aircraft design

German aircraft specialist Flight Design is using HexPly M79 for composite parts on its F2 aircraft.

Read More

.jpg;maxWidth=300;quality=90)