Bonding

Determining steel/composite failure load of bonded repair assemblies

Bureau Veritas and partners use a novel equivalent interface test specimen and simulation to predict failure load in bonded composite patch repairs to steel structures.

Read MoreSubmit abstract to speak at CW Bonding and Welding Tech Days in April

Online event in spring 2025 will feature six presentations exploring reliable methods for the assembly and joining of composite components. Abstract deadline is Feb. 3, 2025.

Read MoreAnalySwift receives NASA STTR contract to enable second-use spacecraft infrastructure

Together with Purdue, AnalySwift aims to develop a composite heater layer and a novel software tool or module to achieve assembly, disassembly of thermoplastic composite joints in space during long-duration missions.

Read MoreIPSA acquires bonding adhesives based on MMA technology

IPS Adhesives (IPSA) introduces a line of adhesives using acrylate and MMA technology from L&L Products for the bonding of dissimilar materials such as metals and composites.

Read MorePlasma treatment elevates aerocomposites surface preparation

CAMX 2024: Enhanced material performance and structural integrity, as well as reduced environmental impact is possible through Plasmatreat’s Openair-Plasma process.

Read MoreControlled polymer ablation technology seeks to redefine surface prep

CAMX 2024: Plasma Bound’s CPA technology, powered by quality control system Vulcan, applies atmospheric pressure plasma to achieve high-level composite bonding.

Read MoreTFP glass veils prove integral for fiber-metal laminate applications

A recent study conducted on vacuum-infused thermoplastic fiber-metal laminates has highlighted the performance benefits behind using TFP’s nonwovens for consistent, uniform bondlines and interfacial bonding.

Read MoreSolvay expands range of FusePly covalent bonding for composite structures

FusePly 250 technology, designed for 250°F to 350°F composite bonding, offers optimized bond reliability and high part performance.

Read MoreHigh-strength, nondestructive adhesive-bonded fasteners

CAMX 2023: Rotaloc bonding fasteners come in a variety of baseplate styles, threads, sizes and materials for high-strength, nondestructive bonding with fiber-reinforced composites and thermoset/thermoformed plastics.

Read MoreAdhesives, sealants meet aerospace and defense specifications

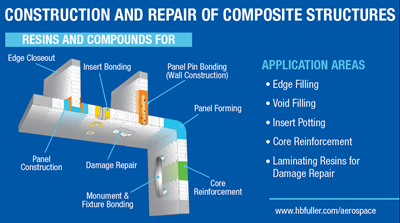

CAMX 2023: H.B. Fuller Aerospace manufactures, packages and delivers a variety of sealants, structural adhesives, low outgassing epoxy systems and more to industry and customer requirements.

Read More

.jpg;maxWidth=300;quality=90)