TFP glass veils prove integral for fiber-metal laminate applications

A recent study conducted on vacuum-infused thermoplastic fiber-metal laminates has highlighted the performance benefits behind using TFP’s nonwovens for consistent, uniform bondlines and interfacial bonding.

A recent study conducted by the University of Edinburgh (Scotland) on vacuum-infused thermoplastic fiber-metal laminates has highlighted the performance benefits of Technical Fibre Products’ (TFP, Burneside, U.K.) 6 gram/square meter (g/m2) glass nonwovens as adhesive carriers within fiber metal laminates (FMLs).

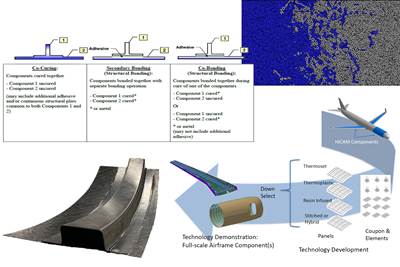

FMLs combine layers of composites and metal, creating a distinctive set of material properties that provide an effective balance of the advantages and disadvantages of their constituents. Initially developed for the aerospace industry, FMLs are lightweight, have a high damage tolerance and demonstrate good fatigue, corrosion and impact properties. According to TFP, the versatility and mechanical properties of FML technology show promise for expansion into other sectors as well, such as wind energy and marine transport, especially when combined with new reactive thermoplastic systems.

Combining these technologies presents challenges, however, particularly the optimization of the metal-composite interface for good adhesion. The constituent materials are dissimilar, potentially causing weak interfacial bonding leading to delamination and loss of integrity.

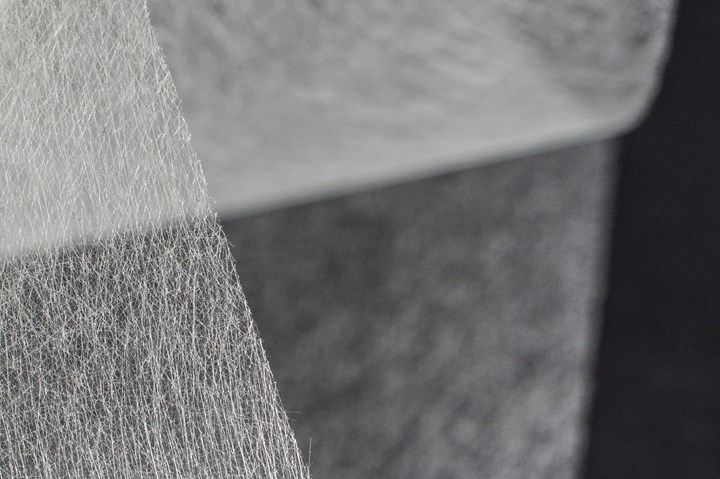

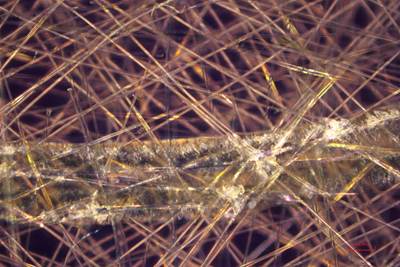

The study, titled “Vacuum-infused thermoplastic fibre-metal laminates – Advances in bonding and recycling,” published in Materials Today Communications, evaluates the use of nonwovens as a carrier for the adhesive to improve the bondline uniformity and interfacial bonding, the latter of which is characterized by a high interlaminar shear strength (ILSS). TFP, a James Cropper company, manufactures high-quality, lightweight nonwovens which are used extensively in the aerospace industry as a carrier or support for adhesive films in more traditional composite layups. They facilitate uniform wetout of adhesive, setting the bondline to ensure a defined and consistent film thickness, while ultimately improving the resilience and handling of the final product.

This study investigated the strength of the bonding within fiber-metal laminates (FMLs), evaluating the impact of using three different glass fiber carrier veils with areal weights of 6, 17 and 34 g/m2. The FMLs were manufactured using a standard vacuum infusion process, with an adhesive carrier (fabricated using TFP’s glass veil and methacrylate adhesive) incorporated between the layers of composite and aluminum — the stacking sequence of each FML was [0/Al/0], with adhesive carrier between each layer.

The laminates were subjected to short beam shear testing to evaluate the ILSS and determine which carrier delivered the most effective bonding. The results indicated that TFP’s 6g/m2 lightweight fine glass veil performed best; the thin, highly porous veil architecture enabled rapid and consistent impregnation with the adhesive to create a thin, uniform bondline.

The study demonstrates the importance of the use of TFP materials in this area, enabling the use of FMLs in new sectors and applications. Key takeaways include:

- Ensuring a consistent and uniform bondline is important for the successful transition of FML technology to an industrial scale. The integration of TFP’s lightweight fine glass as an adhesive carrier enables the necessary control over bondline thickness and maintains uniformity.

- A thin glass fiber veil can be used as an adhesive carrier to improve bondline uniformity without reducing the ILSS which would indicate a disruption in interfacial bonding. Measurement of the ILSS, a critical composite property, indicates optimized results with TFP’s 6 gsm fine glass veil.

“TFP’s lightweight veils are well established as effective adhesive carriers in aerospace applications,” TFP technology manager, Mandy Clement, says. “This new study provides valuable insight into how they can be similarly used in emerging composite technologies. The veils facilitate consistent fabrication and can potentially accelerate FML adoption.”

In addition to the performance characteristics outlined in the study, TFP’s veils offer several advantages when used as a carrier substrate, improving the resilience and ease of handling of the film or fragile material with the minimum possible weight addition. The uniform fiber distribution sets the bondline and enables an even wetout of the adhesive during production.

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreRead Next

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreStudy demonstrates improved abrasion resistance using TFP aramid nonwovens

Study shows aramid veil acts as a sacrificial layer to protect the underlying reinforcement, improves durability and extends composite structure lifespan.

Read MoreFiber-metal laminates in the spotlight

Interest in FMLs is growing again as aeroengineers search for lightweight solutions adaptable to new narrowbody commercial aircraft.

Read More