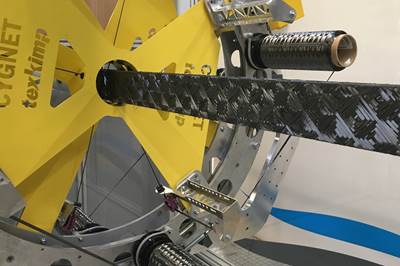

Braiding

NWCC, Cygnet Texkimp collaboration to advance data on winding capability for composite parts

Research project to demonstrate damage tolerance and impact resistance of composite parts manufactured with new multi-axis winder and 3D winding technologies for further development and commercialization.

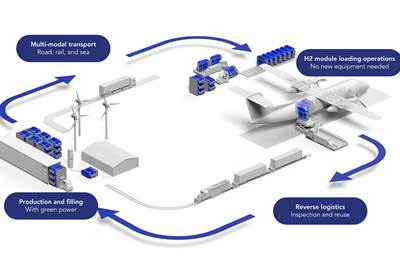

Read MoreUniversal Hydrogen Series A funding to build and test full-scale hardware for hydrogen commercial aircraft

$23.5 million in funding to set Universal Hydrogen on a path to have carbon-free airplanes using composite tanks in commercial service by 2025.

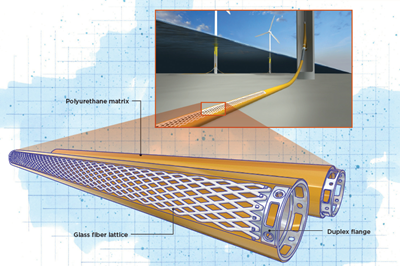

Read MoreComposites protect subsea cables for offshore wind power

Balmoral uses FRP to improve installation, performance and service life while reducing cable failures in rough seas.

Read MoreHP-RTM as a means to reduce hydrogen tank packaging space and cost

BBG Gmbh & Co. KG has developed molds for producers of type IV CFRP tanks, integrating automation and sensors for faster, cheaper production of adjustable-length hydrogen storage cylinders.

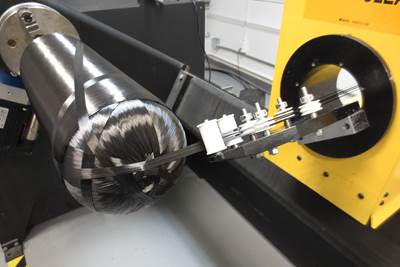

Read MoreCollins Aerospace invests in braiding technology, secures funding for next-gen components

The multi-axis composite braider will be used to prove out production for complex-shaped components like pressure vessels, battery enclosures and more.

Read MoreHawthorn Composites awarded structural inlet duct manufacturing contract

Manufacture of inlet ducts for Kratos unmanned combat aerial vehicle involves an automated dry fiber overbraiding process, VARTM infusion and oven cure.

Read MoreCarbon fiber windsurf fin incorporates Sicomin bio-based epoxy resin

Sicomin GreenPoxy 33 meets high-performance windsurfing fins requirements, accommodating significant loads, high torsion stiffness and flexibility.

Read MoreUniversal Hydrogen uses dry braided carbon preform tanks as part of plan to decarbonize aviation

Twin-tank module offers low capex option for regional carriers to convert to clean fuel.

Read MoreBBG presents self-closing HP-RTM molds for CFRP compact hydrogen tank production

The autonomous concept, sufficient for series production, enables lower investment costs. Up to 15 cylinders can be produced simultaneously per operation.

Read MorePart 2: Performance and safety benefits of prepregs

Returning with his second installment, Brian Bishop discusses the performance and safety benefits to using prepreg, and the value they can bring to composites fabricators.

Read More