Illustrated by Susan Kraus

- FRP mechanically locks to end connectors instead of relying on unpredictable PU bonding.

- 200% increase in axial tension and 150% increase in bending stiffness improves control in rough seas.

- Reduced creep improves fatigue life, guaranteeing performance for the

life of the wind field. - Improvements achieved without having to requalify new PU materials.

Offshore wind has grown from 1% of global wind turbine installations in 2009 to more than 10% in 2019 with 6.1 gigawatts (GW) of capacity installed, according to a 2020 report by the Global Wind Energy Council. That percentage is estimated to double by 2025 when annual installations will reach 21.5 GW. By 2030, projected installations will surpass 31 GW, which translates into an annual total of more than 2,060 to almost 2,600 turbine installations, based on the 12-15-megawatt (MW) models set for serial production by 2024.

Offshore wind turbines provide carbon-free, utility-scale power generation that is increasingly cost-competitive with coal and natural gas. The levelized cost of electricity (LCOE) for offshore wind has dropped 67.5% since 2012 to US $84 per MW-hour and is expected to reach US$58 per MW-hour by 2025, thanks to larger turbines and GW-scale projects.

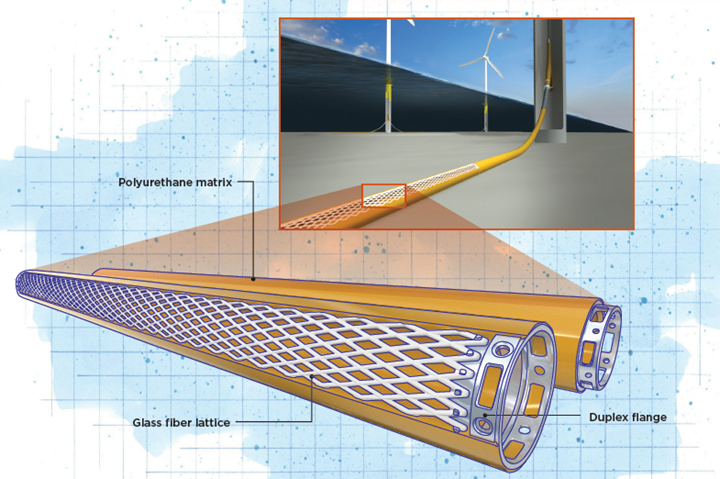

However, building and installing such behemoths is only one part of the challenge. Each turbine must also be connected via high-voltage (33- or 66-kilovolt) cables to an offshore substation, and then to an onshore power grid. These subsea power cables must be protected as they exit the wind turbine monopile foundation and bend to the ocean floor where they are typically covered. Moreover, the cable protection systems must resist saltwater and subsea pressures, excessive bending from ocean currents and storms, and abrasion from rock piles around the monopile foundations to ensure that the electric power in the cable is not interrupted. Also, damage to cables would be difficult and time-consuming to repair, thus maintenance must be kept to a minimum.

Balmoral (Aberdeen, Scotland) is a pioneering product design and manufacturing company, established in 1980. Though well known for meeting the extreme demands of the oil and gas industry, the company has a long history in both glass fiber-reinforced polymer (GFRP) and advanced composite products for a range of industries, including water tanks, wind turbine blades, wave and tidal energy components, subsea tree components and protection covers, guides and centralizers for offshore tubulars and specialized high-volume moldings.

“We had to understand the product behavior in terms of fatigue performance and long-term aging characteristics including UV, temperature, hydrolysis and hydrothermal aging.”

Balmoral FibreFlex is the company’s new high-performance protection system for subsea power cables in the offshore wind sector. Its innovative glass fiber lattice, produced by a robotic winder, reinforces an elastomeric polyurethane matrix and mechanically locks into each segment’s end connectors. This design achieves a 200% increase in tensile strength and 150% increase in bending stiffness versus unreinforced polyurethane systems, as well as substantially improved fatigue and creep resistance, ensuring 20 or more years of service in sea conditions that are increasingly unpredictable. Equally important is the ability of this composite design to meet thermal requirements for maximum electrical power delivery and wind industry cost requirements through an automated production process.

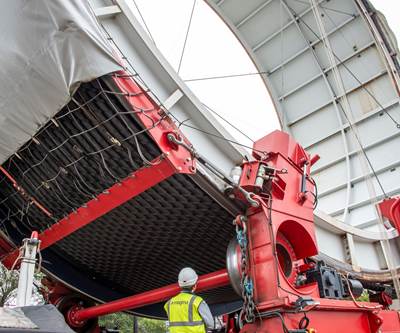

Reliability for life of field in extreme environments. Balmoral’s patented fiber-reinforced polyurethane FibreFlex cable protection system — shown here being tested on the company’s test rig — improves stiffness and fatigue to better protect subsea cables carrying power from offshore wind turbines, especially in rough weather. Photo Credit for all images: Balmoral

Just adding fiber is not enough

“We do a lot of cable protection for oil and gas and saw a growing need in the renewable energy sector,” says Fraser Milne, engineering and projects director at Balmoral. “The FibreFlex product came through acquisition of a company that had developed the product but couldn’t get the technology to work properly. The thought was to just add fiber and that will make it stronger, which equals better.” However, as explained by Dr. Aneel Gill, product R&D manager at Balmoral, “their use of fiber actually made the product quite brittle in terms of its strength profile. Thus, we had to put the product through its paces in lab work and testing to understand its performance and limitations.”

“We looked at fatigue properties and at stiffness, which are absolutely critical as design parameters,” Gill continues. “How the fiber affects the stiffness of the polyurethane is very important. We had to understand the product behavior in terms of fatigue performance and long-term aging characteristics including UV, temperature, hydrolysis and hydrothermal aging.” He notes that fatigue affects the stiffness profile of the fiber/polyurethane composite. “We also had to understand how the production process affects the properties — for example, wetting out the fibers with polyurethane, which is key,” says Gill.

In the end, Balmoral completely characterized the glass fiber/polyurethane composite. Such fiber, polymer and composites testing is done at the company’s own test labs onsite. “There are no datasheets for this kind of composite,” notes Gill. “Although the polyurethane we use is a thermoset, it is at the other end of the flexure profile spectrum from what they use in composite leaf springs, for example. Most composites test houses don’t normally work with such elastomers, while elastomer test houses don’t work with fiber-reinforced composites. So, we are combining two worlds, each completely different in how to design with the material and failure modes, but also in how to handle in manufacturing. We’re combining these to create something which is better than the sum of its two constituent parts, which is a good thing.” But that also requires a significant amount of work upfront, and then more work to understand how to use this superior performance to optimize the design.

Redesigning FibreFlex to perform

Once Balmoral understood the composite material, it then had to rework the design for the performance it wanted to achieve. “Storms, waves and currents move these undersea cables,” says Gill. “Our job is to protect the cable from overbends which exceed the ULS (ultimate limit state), for example, in a 100-year storm. Increasing stiffness in the cable protection system makes it harder for the cable to move. This also increases control of its curvature, prevents kinking and flexing and improves its fatigue life.

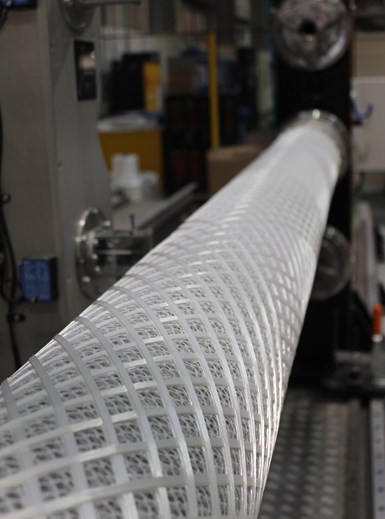

“Thus, we want a design that provides good axial properties and torsional stiffness,” he continues. “For this reason, we use a kind of fiber lattice, similar to how hoses are braided.” This fiber lattice, Milne explains, is produced using a robot that Balmoral had developed with MF Tech (Argentan, France) to wind the fiber in the ±45° direction.

“This delivers the buckling resistance and stiffness we want but at a very thin wall thickness,” Gill emphasizes. Why is this important? “Because the cable protection system is effectively placing a large insulator onto a power cable, which generates heat. The thicker the protection, the more heat it traps, which can then limit its power-carrying capacity. So that's where knowing how to design the fiber technology allows us to protect the cable while maintaining its performance. Our design also allows operators to apply ballast on our lines, when necessary, and not have issues such as long-term creep rupture,” says Gill. “The fiber reinforcement limits the effect of creep rupture, which is a known failure mode for unreinforced polyurethane protection systems.”

“We're seeing a big movement now toward composites. We understand what composites can do for them and how to develop designs that will deliver the performance and cost required.”

The robot-wound fiber lattice Balmoral devised adds another key design advantage. FibreFlex cable protection is produced in 4- or 5-meter-long segments and then joined to form a continuous hose into which the subsea power cable is threaded. The connections are male to female flanges made from Duplex (austenitic and ferritic) stainless steel, guaranteed to provide decades of subsea performance. These are integrated into each hose segment via the fiber lattice. “Each flange has 40 to 50 fingers,” explains Milne. “Our robot will run the fiber from one end of the pipe to the other, catching each of these fingers to create the lattice. Thus, the flanges are mechanically attached to the fibers and not bonded.”

Subsea solutions. Finished Balmoral FibreFlex cable protection system segments with integrated stainless steel male and female flange end fittings.

This, explains Gill, creates a very robust product with reduced risk. “Conventional protection systems often bond the end fittings into the unreinforced polyurethane,” he notes. “So, you have a piece of malleable plastic that may exhibit 100% or 200% elongation to break, and you must bond that to a stainless steel substrate. This introduces a number of issues, including very tight control over surface preparation, making sure that all primers are compatible with the type of polyurethane you’re using and then testing to write off for my customer that this bond will endure for 30 years in a subsea environment. If we eliminate sole reliance on that bonding, we take all of that risk away.”

Gill concedes one alternative would be mechanical attachment to the stainless steel flanges. “There are methods for doing that, but you cause other issues like large stress raisers, where the polyurethane is now on a fixed anchor point,” he says. “This can create high stress concentrations, and therefore you need larger cross-sections to deal with those, but then you jeopardize the necessary thermal performance.”

Precision manufacturing for commodity cost

“Even though Balmoral is mostly a bespoke product manufacturer, we understand the cost target required for the wind industry, which is much more challenging than oil and gas,” says Milne. “FibreFlex is expensive technology that we have had to commoditize via a smart design and automated manufacturing.” He points out that the robotic winder is not a radial braiding machine. “It is direct fiber placement. Once we have the lattice with the two end flanges connected, we place this into a matched metal mold, close the mold and inject the polyurethane so that the lattice is embedded in the polymer.” The finished composite laminate is 30 millimeters thick, while the diameter is chosen from a standard range to accommodate various cables used in the offshore wind market.

“This process demands high precision control in the mold,” Milne emphasizes. “We heat the mold to 100°C and that temperature must be controlled to get the polyurethane viscosity right for impregnation of the fiber.” With regard to production cycle time, Gill explains, “we infuse, cure and demold in minutes.” He notes this is indeed very short compared to the process times used with the elastomeric fluoropolymers in the early days of oil and gas subsea umbilicals. “Our process speeds depend on maintaining tight process control,” says Milne. “We’ve invested a huge amount of money in our plant and equipment, and we work with all the polyurethane and fiber manufacturers to make sure that we’re within the correct operating envelope.”

Pioneering quality, standards and new products

FibreFlex products are qualified to each customer’s specifications. “There are standard specs for polymer products in oil and gas,” says Gill, “but this product is for offshore wind, not oil and gas, and it is a fiber-reinforced composite, not an unreinforced polymer. So, we base product qualification on first principle, risk-based testing, and then test per the client’s specification. For example, a client will come to us and give the design and service envelope. We have a lot of experience and understanding in how to translate this into product requirements in order to validate the performance against their specification.”

Smart design, automated manufacturing. Balmoral has designed FibreFlex to provide the necessary axial and torsional stiffness at a slim cross-section but also automated manufacturing using a robotic winder, to meet the challenging requirements for process control and low cost demanded by the offshore wind industry.

“All of the fatigue and creep testing is actually done onsite to our specifications,” he continues. “For steel, it’s easy; go to the library and pick your material properties and test standards. For S-N curves to qualify fatigue performance for our particular composite, for example, that just doesn’t exist. We have to create those. There are composite testing standards, but not for renewable energy cable protection systems specifically. The industry is still emerging and is just not there yet. You have to have the experience to pick standards which are valid and then we do risk-based testing, validating fatigue, flexing, hydrolysis, etc.”

“We’re not a one-trick pony with composites,” notes Milne. “We’ve long made standard GFRP covers using vacuum infusion for protection of subsea wellheads and other equipment. These are more than 100 millimeters thick and can be 12 meters by 8 meters or larger. We also make composite tank covers using an ergonomic shape where the loads are all transferred laterally into the flanges to reduce thickness. So, again, we look at how to use the fiber and good design to cut weight by 30% in these tank lids, which can be up to 36 meters in diameter.”

He says that although FibreFlex is Balmoral’s first commercial series product for renewable energy, “we are also working heavily on wave energy, tidal energy and other wind energy applications. We have done a lot of development processes with various suppliers and for us, all of the work is in composites.” He points out that a lot of these new renewables technologies started with components in steel, “but we're seeing a big movement now toward composites. We understand what composites can do for them and how to develop designs that will deliver the performance and cost required.”

Related Content

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreRead Next

Thermoplastic composite pipe on the rise in the deep sea

Demonstrators, pilot programs and qualification efforts are paying off as thermoplastic composite pipe (TCP) makers take orders for deep-sea oil and gas applications.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More