Pressure Vessels

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreMobile Pipeline Titan module orders further RNG, CNG adoption

Hexagon Agility received orders from RenewGas Transportation and Permian Global Inc. and CORE for delivery of its reliable and safe composite pressure vessel modules.

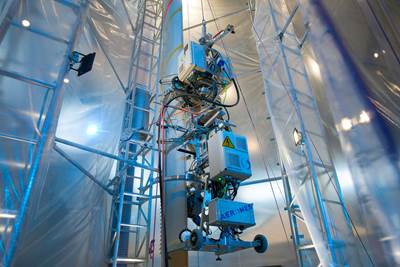

Read MoreAerones unveils modular robot for Level 1-3 wind turbine maintenance, repair

Resilient, full-service system can perform a variety of tasks five times faster and more safely than human technicians, while proactively addressing extreme erosion progression.

Read MoreTPI, WindSTAR create digital twin for wind blade manufacturing

Machine learning framework provides real-time feedback during composite fabrication process, with some cases achieving 95% predictive accuracy and computation faster than physics-based simulations.

Read MoreMingYang reveals 18-MW offshore wind turbine model with 140-meter-long blades

The Chinese wind turbine manufacturer surpasses its 16-MW platform, optimizes wind farm construction costs for 1-GW wind farms.

Read MoreStrohm secures second “Jumpers on Demand” contract from ExxonMobil

On-site service includes readily available 24+ carbon fiber-reinforced PA12 jumpers to be installed at depths of 1,700 meters for water and gas (WAG) application.

Read MoreContinuum targets facility capacity, transforms composite materials to advance wind blade recycling

The Denmark company details a CO2-neutral transformation technology to make 100% recyclable wind blades, plans to build six recycling facilities.

Read MoreRegen Fiber launches eco-friendly wind blade recycling process

Regen Fiber’s sustainable recycling process keeps wind blades out of landfills by converting them into raw materials for use in asphalt, composite products and more.

Read MorePlastic Omnium, Shenergy Group JV to accelerate hydrogen development in China

Pilot project line in Shanghai for Type IV hydrogen systems will be in place by 2025, and a mega-plant with a 60,000-vessel capacity by 2026.

Read MoreTPI, GE extend supply agreements, plan next-gen wind blade design collaboration

TPI has manufactured wind blades for GE since 2008. New commitments will lead to the development of new blade types and potentially more production lines in 2023.

Read More

.jpg;maxWidth=300;quality=90)