Molds/Tools

CAMX 2019 exhibit preview: RAMPF Group

RAMPF Group Inc. is presenting its full range of model, mold and tool engineering materials for the automotive, marine and aerospace industries.

Read MoreCAMX 2019 exhibit preview: Design Concepts

Design Concepts is emphasizing its closed mold applications for both tooling and manufacturing in the entertainment, simulation, aerospace and wind energy markets.

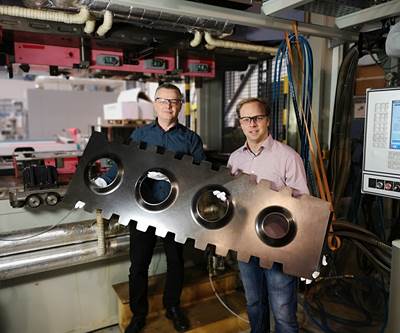

Read MoreCAMX 2019 exhibit preview: Weber Manufacturing Technologies Inc.

Weber will showcase a live nickel vapor deposition (NVD) out-of-autoclave demonstration for a Class A automotive body panel, demonstrating the tool’s rapid heating and cooling capabilities at CAMX 2019.

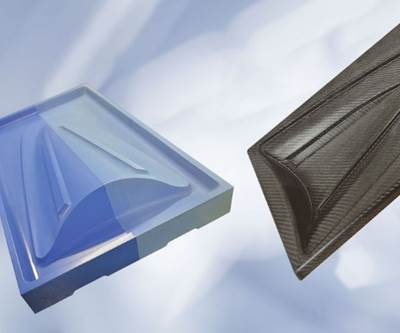

Read MoreCutting the cost and time of tooling for composites

New 360 material achieves CFRP/Invar tool performance with less investment.

Read MoreVABO Composites to build superstructure, mast for Royal Van Lent yacht

Lightweight marine composites production to be further advanced using robotic automation.

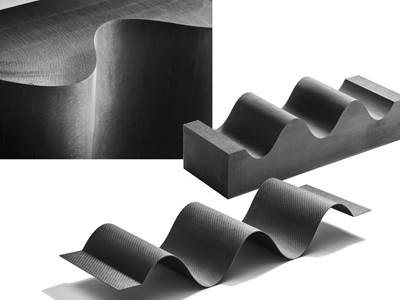

Read MoreCarbonPro box: new forming process

From materials to assembly, the carbon fiber composite CarbonPro box manufacturing process features innovative, automated preforming technologies.

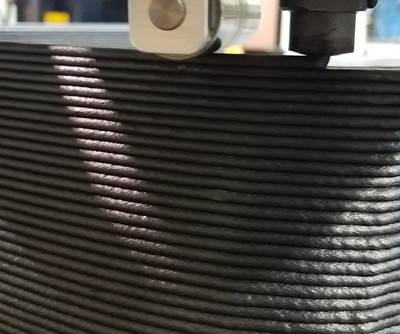

Read MoreBig additive machines tackle large molds

In commercial aerocomposites fabrication, molds reign supreme, but they are expensive. Large-format additive manufacturing systems are poised to make production-ready molds quickly and affordably.

Read MoreHP-RTM for serial production of cost-effective CFRP aerostructures

Merging automotive process and tooling with aerospace quality to meet increasing production rates.

Read MorePlant Tour: STELIA Aerospace, Méaulte, France

Supplier of Airbus fuselage sections pushes boundaries of hybrid aerostructures production, assembly and thermoplastic composites.

Read MoreInnovate UK and IACMI composite competition now open

The U.K.-based competition will award funding for disruptive composite technologies.

Read More

.jpg;maxWidth=300;quality=90)