Resins

Suprem thermoplastic composites contribute to pressure vessel expansion

High-quality, high-performance UD thermoplastics are dedicated to industrializing recyclable Type III, IV and V pressure vessels.

Read MoreOffshore wind-to-hydrogen infrastructure development incorporates Strohm TCP, Siemens Gamesa electrolyzers

Concept for decentralized green hydrogen generation replaces power cables with subsea thermoplastic pipes to transport energy generation from turbine to shore.

Read MorePatent-pending welder rapidly melts thermoplastics

The FlatJet Welder, designed for thermoplastic components of all sizes, blasts a thin, directed jet of uniform, high-temperature air/gas for a fast, full-surface melt.

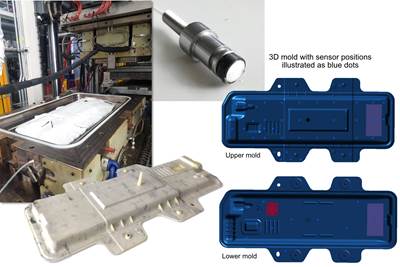

Read MoreCustomizing ultrasonic sensors for composites process optimization and control

University of Augsburg developed sensors for the CosiMo project’s digital twin and closed-loop process control of EV battery box cover demonstrator, and now moves forward with the AI Production Network for industry collaboration.

Read MoreVETERIA21 project seeks to optimize thermoplastics for adoption in EV battery casings

Aimplas and the Valencian Regional Government’s Ministry of Innovation, Universities, Science will develop more efficient transformation processes for thermoplastics, and reduce battery weight, energy consumption.

Read MoreMETEOR project studies optimization of thermoplastic prepreg production

Completed project aimed at optimizing and reducing the cost and energy involved in CFRTP prepreg manufacture, with the end goal of industrialization.

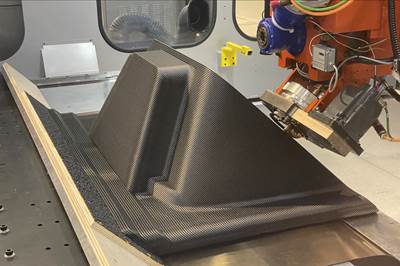

Read MoreSAM|XL receives grant for composites research towards sustainable aviation

Jointly with TU Delft Faculty of Aerospace Engineering, the SAM|XL field lab will receive €4.9 million for projects in liquid hydrogen composite tanks, thermoplastic composite aerostructures and smart maintenance and repair.

Read MoreSetforge to serially produce composite parts using 9T Labs technology

The former metal component forger seeks the disruptive manufacture of high-performance CFRTP parts using 9T Labs’ Red Series Additive Fusion Solution platform for current and new markets.

Read MoreThermwood adds angle layer printing feature to LSAM large-scale AM systems

The ability to print at a 45º angle adds to the system’s current horizontal and vertical orientation capabilities, enhancing the flexibility of producing large-scale composite thermoplastic parts.

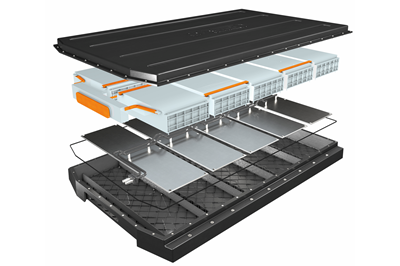

Read MoreLanxess, Kautex Textron explore D-LFT for EV battery housings

Research cooperation substitutes steel and aluminum with a continuous fiber-reinforced thermoplastic technology demonstrator for advantages in weight, functional integration and mass production.

Read More

.jpg;maxWidth=300;quality=90)