Thermoplastics

NREL, Arkema research recyclable, thermoplastic composite wind turbine blades

The National Renewable Energy Laboratory and partners aim to develop more sustainable, longer-lasting turbine blades that are less expensive to manufacture.

Read MoreAZL, EconCore, Audi partner to develop composite battery casings

A new project aims to identify potential opportunities and challenges for composite materials within the electric vehicle battery enclosure market.

Read MoreICP thermoplastic tension members enable flex strength improvement

TM continuous fiber-reinforced rods help plastic parts perform more like metal by increasing load capacity and overall stiffness of the molded part.

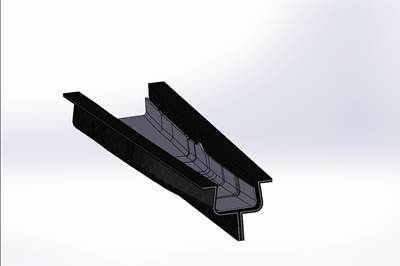

Read MoreHybrid, large-format additive tooling: Lighter, faster, less costly molds for big parts

Additively manufactured cores, CFRP face skins produce large tools for prototype, low-volume aerostructure parts.

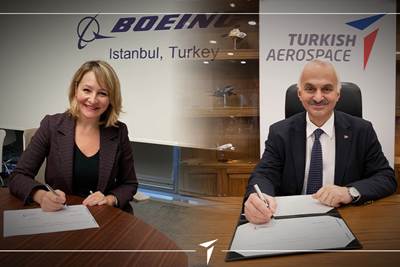

Read MoreTurkish Aerospace, Boeing partner to produce thermoplastic composites

Per the partnership, Boeing will provide technical support to establish a fully automated facility in Turkey for the production of thermoplastic aerospace components, as well as training technical personnel.

Read MoreNext-generation composites materials and processes explored

A supplement with the November 2020 issue of CompositesWorld takes a close look at some of the technologies that are driving innovation in the composites industry.

Read MoreLoudspeaker membranes incorporate Stylight thermoplastic composite material

INEOS Styrolution’s StyLight Aesthetic S C245 carbon fiber sheet became the top material choice for a loudspeaker components manufacturing company due to its acoustic properties.

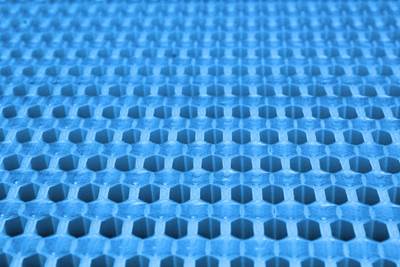

Read MoreWEAV3D composite material approved for infrastructure reinforcement applications

Durable, strong and resistant to corrosion, the thermoplastic-based lattice material is suitable for use in Oldcastle Infrastructure’s polymer concrete and sheet molding compound (SMC) composite products.

Read MoreQ&A with Ethan Escowitz, CEO, Arris Composites

Ethan Escowitz visits with CW Talks to discuss Arris Composites’ Additive Molding process.

Read MoreDieffenbacher D-LFT line enables large thermoplastic component production

The high-capacity direct-long-fiber thermoplastic (D-LFT) molding line has been further modified into a one-stage extrusion process, and produces 100% recycled thermoplastic components.

Read More

.jpg;maxWidth=300;quality=90)