ICP thermoplastic tension members enable flex strength improvement

TM continuous fiber-reinforced rods help plastic parts perform more like metal by increasing load capacity and overall stiffness of the molded part.

Fig. 1. Tension Members are continuous fiber-reinforced rods that are inserted in the mold and strategically placed at the bottom of a molded rib. Photo Credit: ICP

Integrated Composite Products (ICP, Winona, Minn., U.S.) has developed selective polypropylene (PP) thermoplastic reinforcements, also known as Tension Members (TM), to help improve the performance of plastic parts. The reinforcements are said to offer mechanical engineers a lightweight option that retains significant improvements in strength, stiffness and impact properties, for a reduced cost. According to ICP, designers will no longer have to settle for increasing weight and/or the dimensions of the part.

The TMs are essentially continuous fiber-reinforced rods (Fig. 1) that are inserted in the mold and strategically placed at the bottom of a molded rib before the polypropylene plastic is injected. When a molded part is stressed, notes ICP, it normally fails at the bottom of the rib. By placing these “rods” directly at the bottom of the rib, the force is said to be distributed across the entire rib, dramatically increasing the load capacity and overall stiffness of the molded part.

Test Panel Graphs

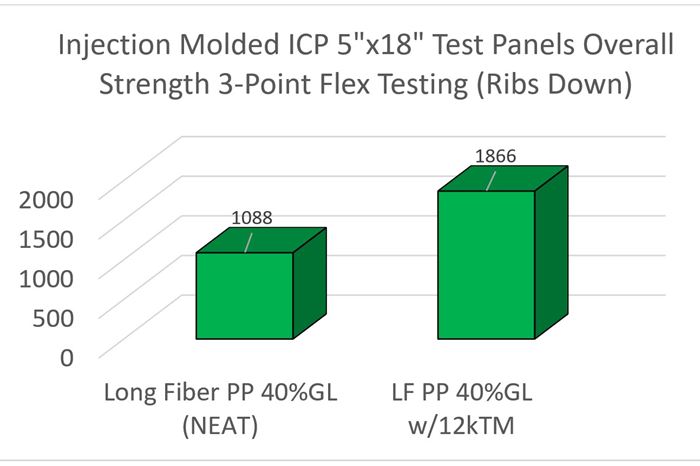

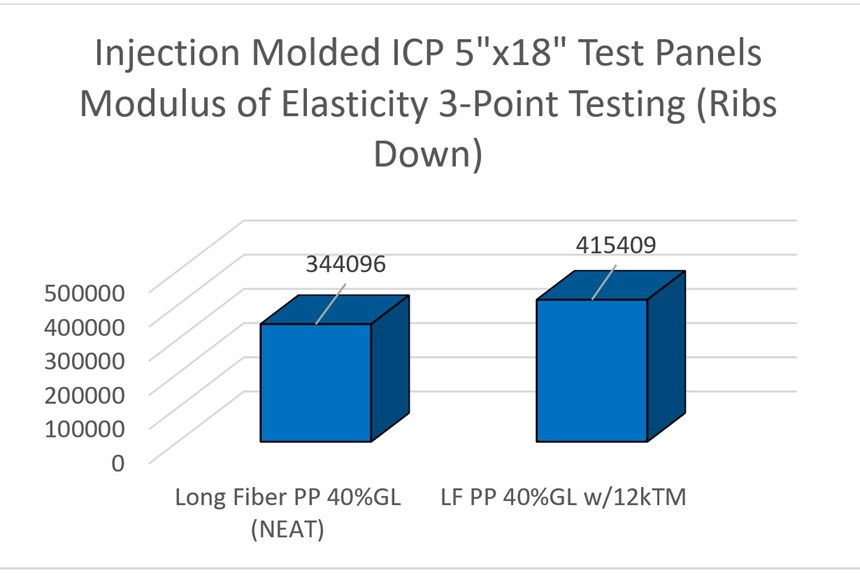

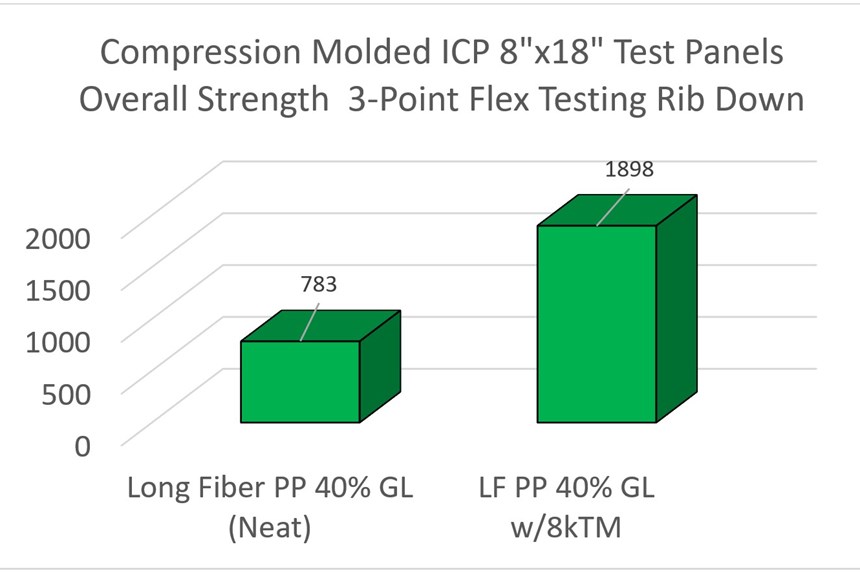

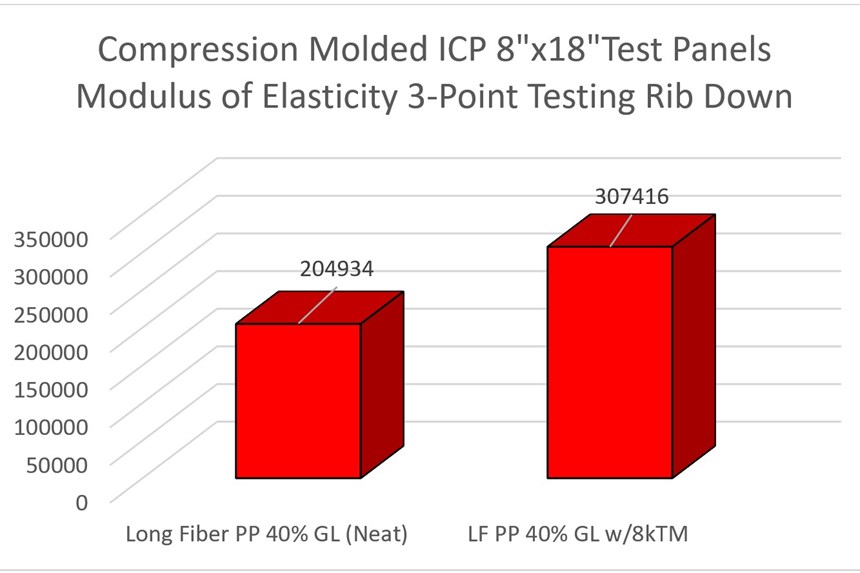

For example, in injection molded 5-inch-wide x 18-inch long x 1-inch deep panels processed in 40% long fiber glass-filled PP, ICP’s thermoplastic tension members provide flex strength improvements of 72% and flex modulus improvements of 21% without increasing part weight (Fig. 2ab). In compression molded 8-inch wide x 18-inch long x 1-inch deep panels using the same 40% long fiber glass-filled PP, the property improvements are said to be even greater, obtaining flex strength improvements of 142% and flex modulus improvements of 50%, again without impacting part weight (Fig. 3ab). Further, the use of PP TMs in conjunction with glass-filled PP ensures the entire part is recyclable.

Tension Members are manufactured and sold based on the number of glass filaments within the TM and the overall length of the TM. For example, an 8,000-filament product has an overall diameter of 0.090 inch and sells for around $.034 (i.e. 3.4 cents) per foot at high volume. A 12,000-filament product is 0.160 inch in diameter and sells for approximately $.061 (i.e. 6.1 cents) per foot at high volumes. ICP can vary the number of filaments in the TM to meet the application needs and rib size. Production is done in the company’s Winona, Minn., site and product is readily available and applications are being sampled and developed.

Related Content

-

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.