Psyonic’s bionic prosthetic hand combines pressure sensors in the fingertips, polymer 3D printing and a carbon fiber composite outer shell. Photo Credit, all images (including the image in line with title): Psyonic

As a Ph.D. student at the University of Illinois Urbana-Champaign, Aadeel Akhtar began working on a bionic prosthetic hand concept that would be faster, more functional and more affordable than alternatives on the market. Stemming from his initial Ph.D. research, Akhtar founded Psyonic (San Diego, Calif., U.S.) in 2015 to commercialize what is now called the Ability Hand.

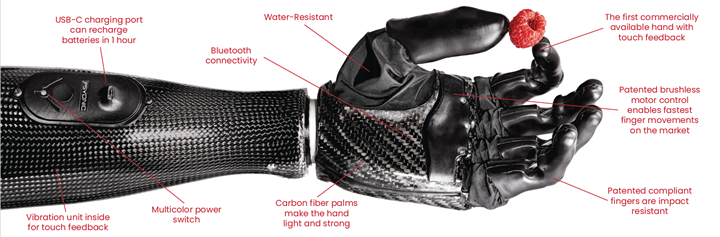

Psyonic’s prosthetic hand has two main components: a socket that fits onto the rest of the limb, and the hand itself that attaches into the socket. The sockets, which feature an exterior layer of carbon fiber composite, are custom-built by prosthetics clinicians to fit individual patients. The hand components are made in-house by the Psyonic team, including electronics, silicone molding, tooling manufacturing, composites fabrication, polymer 3D printing and assembly.

Starting with the first prototype, which was designed from an open-sourced humanoid robot blueprint found online, Akhtar used fused deposition modeling (FDM) to additively manufacture lightweight palm and finger components. From this initial design, four more prototypes were iterated, all using 3D-printed plastic for the exterior hand components.

The composite outer shell enables the Ability Hand to be strong enough to bear weight while weighing less than the average human hand.

These prototype hands worked to prove out the mechanics, but when it came to putting them into actual practice, Akhtar says he and his team realized that the materials they were using wouldn’t cut it. “We started talking to patients and clinicians about other hands on the market, made from steel and injection-molded plastic, and the number one complaint was that they break easily, just from everyday small impacts like hitting your hand on the side of a table when you’re walking,” Akhtar says. “Hands in real life are compliant and flexible, but also rigid in places, so we started looking at ways to do this with our hands.”

For the fingers, instead of 3D-printed polymer, the Psyonic team uses more pliant, injection-molded silicone reinforced with a 3D-printed, flexible, bone-like interior structure.

For the palms and back of the hand, they needed a material that was strong and rigid — but also lightweight. “We could have just used really thick plastic to get the strength and rigidity we needed,” explains James Austin, lead mechanical engineer at Psyonic, “but that adds a lot of weight.” Akhtar explains that prosthetic hands need to be lighter than a typical human hand: Whereas a typical human hand can support its own weight at the wrist, a prosthetic hand needs to be light enough to be easily supported, raised and lowered by the rest of the residual limb.

Exploring lightweight, durable materials ultimately led Psyonic to composites. The next several prototypes leading up to today’s commercial version incorporate a much thinner, 3D-printed plastic palm with a ~2-millimeter-thick carbon fiber composite shell on the exterior.

The current generation hand weighs 490 grams, said to be about 20% less than the weight of the average human hand. “Carbon fiber played a huge role in reducing that weight,” Akhtar says. In addition to low weight, the carbon fiber also “reinforces the plastic to the point where we’re actually able to stand on the palms and not break them,” he adds.

Each hand’s carbon fiber shell is made in two halves. For each half, a sheet of frozen epoxy resin is laid up between two plies of dry carbon fiber fabric or colored hybrid glass/carbon fiber (supplied by Composite Envisions, Wausau, Wis., U.S., or Soller Composites, Franklin, N.H., U.S.) on an aluminum tool that is designed and CNC machined by Psyonic. The assembly is then vacuum bagged and cured in an oven. Once cured, the carbon fiber shells are trimmed and finished with a clear coat, then bonded with epoxy to the 3D-printed palm components before assembly with the rest of the hand.

The end result is an Ability Hand that can move each finger independently, controlled by electrode sensors attached to the residual limb’s muscles inside the socket or via a Bluetooth app. The hand is water-resistant, strong enough to bear weight and features pressure sensors in the fingers to replicate a sense of touch for the user. The hand is covered by Medicare in the U.S. and priced for accessibility.

A limited trial run of the Ability Hand was released in the fall of 2019, followed by a nationwide launch in September 2021. In 2022, the company relocated to its current facility in San Diego, Calif., U.S.

As of early 2023, more than 80 patients are currently using the hand, with more than 20 in use by research labs around the world, including NASA (Houston, Texas, U.S.) and ETH Zurich (Switzerland).

Looking ahead, Psyonic is currently searching for additional investors with a goal of increasing manufacturing scale at its facility as well as continued development for its hands and, eventually, leg prosthetics. In addition, the Psyonic R&D team is working toward optimizing materials and manufacturing methods, looking into select laser sintering (SLS) or other 3D printing methods to potentially replace the 3D-printed plastic components in the hand with carbon fiber-reinforced nylon for increased strength and optimal thermal properties.

Related Content

Pull-wound carbon fiber poles enable lightweight, compact, rigid emergency stretcher

Based on military feedback, Epsilon Composite developed an optimized, foldable stretcher that combines telescopic pull-wound carbon fiber tubes.

Read MoreMulti-material, self-sensing, 3D-printed scoliosis braces

Startup Fited and Brightlands Materials Center have developed a lighter weight, thinner CFRP corrective brace, including pressure sensors made from continuous carbon fibers.

Read MoreNanomaterials optimize performance of space-ready carbon fiber composite panels

A recent ESA project led by Adamant Composites aimed to mature nanomaterial-enhanced CFRP for lighter weight, more thermally and electrically conductive materials for manufacturing satellite structures.

Read MoreBio-based epoxy, recycled materials increase sustainability of all-terrain snowboards

Aiming for a smaller environmental footprint while maintaining high performance, Salomon’s Highpath snowboard line incorporates bio-based epoxy, glass and basalt fiber stringers and recycled materials.

Read MoreRead Next

CFRP: Opportunities in orthopedics

Carbon fiber has a niche, but can it secure a larger piece of a high-growth pie?

Read MoreC-FREX exoskeleton depends on CFRP for unpowered movement

C-FREX uses a novel design and CFRP to overcome the heaviness and weakness of metallic exoskeletons.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)