Videos

Physical testing to characterize composites

Shimadzu Scientific Instruments reviews use of static tests, impact tests, internal observations and fracture observations to assess and characterize the physical properties of composite parts and structures.

WatchVitrimers: The reprocessable thermoset

Vitrimers are not classic thermosets and they are not classic thermoplastics, but they behave like both and as such offer the best of both worlds. CW catches up with Mallinda for an explanation.

WatchNedcam adds CEAD AM Flexbot for 3D printing using DSM materials

The two companies will explore new applications in tooling, large-sized and circular end-use parts.

WatchComposites Academy launches online training with hands-on exercises

Composites Expert and Institut de Soudure partner to provide interactive advanced composites training to students and professionals worldwide.

WatchNemesis Yachts announces all-composite hydrofoil luxury yacht

Powered by a hydrogen-electric battery, solar panels and a wing sail, Nemesis One promises speed, comfort and sustainability.

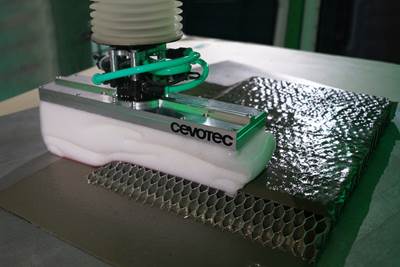

WatchNext-generation automation for high-performance composites fabrication

Cevotec’s Fiber Patch Placement technology uses robot-based systems to automate material layup for complex composite parts and structures, saving 20-60% in production time and costs.

WatchContact-less microsensor targets real-time NDT for composite structures

RVmagnetics’ MicroWire self-monitors composite structures via embedding during the production process. It improves safety, control and real-time data for predictive maintenance.

WatchBladder and caul solutions for trapped & complex composites fabrication

Smart Tooling reviews the function and application of its shape memory polymer tooling bladder and caul solutions for the efficient and cost-effective manufacture of trapped and complex geometry composite parts and structures.

WatchAddcomposites and Effman partner to provide AFP cells for SMEs

Aim is affordable, enclosed composites manufacturing cells for many different processes (AFP, grinding, buffing, sanding, drilling) in North American market.

WatchComposite Bonding & Repair Benefits and Solutions

Film and paste adhesives, wet peel-ply and potting compounds enable the aviation industry to utilize advanced materials that contribute to lightweighting, more efficient designs, and improved sustainability.

WatchThermwood demonstrates vertical layer print additive technology

The new approach for large scale 3D printing was validated via Thermwood’s LSAM system and printed parts up to 5 by 10 by 10 feet.

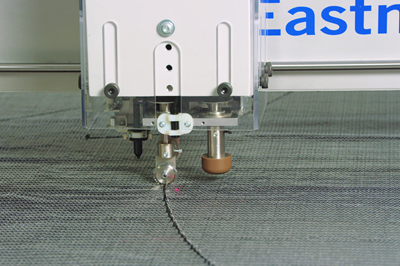

WatchAutomated Cutting of Composites Reinforcement Saves Time and Material, Improves Quality

Automated cutting of reinforcement materials is fast, accurate and reliable. It reduces labor costs and material waste and can substantially boost throughput.

Watch