Additive offerings span viscosity management, reinforcement wetting

CAMX 2024: Patcham USA displays a range of additive solutions for rheology modification, viscosity management, reinforcement wetting and more.

Share

Patcham (Fairfield, N.J., U.S.) is displaying its additive offerings tailored to resin manufacturers, compound producers and reinforced and non-reinforced fabricators. The company incorporates numerous production methods, as well as gelcoat and colorant producers.

Targeting UPR, epoxy and PU resin manufacturers, Patcham exhibits its custom deaerator, the PAT-Add AF86, as well as its upcoming rheology modification technology, PAT-Add-Rheol 259, which is said to provide storage-stable, efficient, high-index thixotropy.

Suited to filled and compound manufacturers, as well as BMC/SMC fabricators, the company is also displaying its latest viscosity management, anti-settle dispersant, thePAT-Add-DA 2250, optimizes performance even at lower viscosities.

Additionally, the PAT-Add-DA2709 dispersant is on display for putty, mastic and adhesive producers. This production aid provides storage viscosity management in highly filled systems.

Gelcoats and pre-dispersed colorant-focused companies may find Patcham’s DA-3325 and U–7510 of interest for its anti-flocculation and color development capabilities.

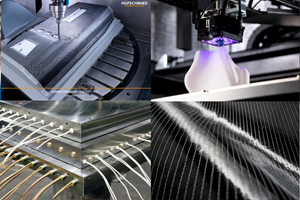

Finally, Patcham continues to feature its PAT-Add FW 1065 reinforcement wetting technology. The company is working to validate its performance in virtually all resin technologies and reinforcements, including carbon and natural fibers. Patcham also intends to provide expertise in metal carboxylate accelerator technology, including Co, Cu, Ca, K, Na and Zn. Its Colorless Co. and water white K are also featured.

Related Content

-

CAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

-

VIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

-

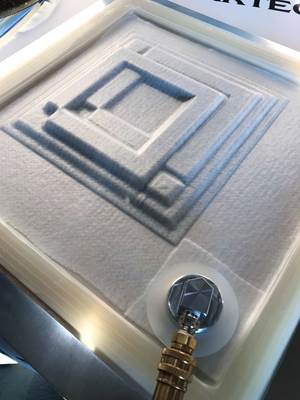

Reusable vacuum bagging solutions for composite applications

CAMX 2023: Smartech underscores its industrial reusable vacuum bagging products for reduced waste, easy debulking and the capability to be used for complex projects.

Related Content

CAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

Read MoreVIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

Read MoreReusable vacuum bagging solutions for composite applications

CAMX 2023: Smartech underscores its industrial reusable vacuum bagging products for reduced waste, easy debulking and the capability to be used for complex projects.

Read MoreWireless strain measurement system for die-cast and injection molding

CAMX 2023: Gefran introduces the QE2008-W, a non-invasive, magnetically mounted strain solution with Bluetooth transmission that uses sensors to accurately measure and maintain equipment quality.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More