Healable thermoset resin achieves ultra-fast composites repair

CAMX 2024: CompPair HealTech solutions give the ability to heal cracks and delaminations in a composite via local heating more than 60 times, available for a range of composite processes.

Share

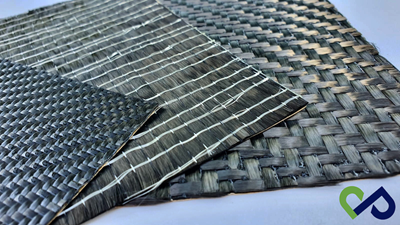

CompPair Technologies (Renens, Switzerland) highlights its HealTech solutions, which feature an embedded healing functionality for ultra-fast repairs, preserving economic value and extending the lifespan of composite structures. The company specializes in providing tailored repair solutions for several composite applications across various industries.

HealTech is a thermoset-based resin system that gives fiber-reinforced polymers (FRPs) the ability to heal cracks and delaminations in 1 minute by locally heating the part from 100°C-150°C. HealTech is suitable for autoclave, out-of-autoclave (OOA) and press curing, as well as for a range of composite processes, such as infusion; currently, CompPair’s portfolio includes prepreg and liquid composite molding (LCM) lines, all of which have customizable fiber options.

CompPair provides pre-impregnated textiles with various reinforcement types and resin systems adapted to autoclave, OOA and press processing. On top of its two current resin systems (CS01 and CS02), the team can support the implementation of bio-based systems, RTM, fire resistant and slitted tape systems.

HealTech, designed to provide benefits under static and fatigue damage use cases, while keeping competitive mechanical performances, achieves:

- +30% crack resistance: CompPair’s composite solution chemistry brings increased toughness to reinforce a composite product’s strength

- 100% damage regeneration: HealTech enables repair in the matrix, including delamination, microcracks and scratches

- +80% damping: Enhanced damping allows better and constant performance throughout the composite part’s lifetime

- 60+ healing cycles: HealTech composites can repair damage in the matrix more than 60 times, while maintaining initial technical properties

- 400 times faster repair times: This drastic reduction enables users to reduce maintenance costs and downtime.

All of CompPair’s semi-products can be transformed into semi-finished parts, including tubes, thermoformable sheets, sandwich panels and monolithic carbon and glass fiber plates.

Related Content

-

Toray jointly wins Infrastructure Maintenance award for steel pipe repair innovation

Together with Tokyo Electric Power Grid and Yasuda Seisakusho, Toray employed in-situ VARTM with carbon fiber sheets to repair steel pipe corrosion on transmission towers, with application extension underway.

-

FACC signs multiyear agreement with Pratt & Whitney for fan case MRO

FACC is growing its component repair services with the repair and overhaul of its customer’s composite PW800 turbofan engines.

-

Belzona coatings expand composite leading edge protection, lifespan

Belzona highlights the use of Belzona 5711 and 5721 to extend the lifespan of 42 wind turbine blades in Denmark facing severe erosion.

Related Content

Toray jointly wins Infrastructure Maintenance award for steel pipe repair innovation

Together with Tokyo Electric Power Grid and Yasuda Seisakusho, Toray employed in-situ VARTM with carbon fiber sheets to repair steel pipe corrosion on transmission towers, with application extension underway.

Read MoreFACC signs multiyear agreement with Pratt & Whitney for fan case MRO

FACC is growing its component repair services with the repair and overhaul of its customer’s composite PW800 turbofan engines.

Read MoreBelzona coatings expand composite leading edge protection, lifespan

Belzona highlights the use of Belzona 5711 and 5721 to extend the lifespan of 42 wind turbine blades in Denmark facing severe erosion.

Read MoreSpirit AeroSystems, Joramco sign MRO services cooperation

MOU agreement will provide customers a wide range of repairs to and services of composite and metallic aerostructures.

Read MoreRead Next

University of Bristol studies mycelium composites as alternative building materials

Affordable, lightweight and sustainable composite materials made from mycelium — mushroom roots — may have potential for packaging materials, insulation panels, floor tiles and furniture.

Read MoreCompPair, SHD form partnership to advance healable composites to market

Collaborative commitment extends to impregnation services, joint product development and commercial endeavors, laying the foundation for sustainable composite solutions.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More