Universal test system, testing fixtures provide standardized composites testing

CAMX 2024: MTS Systems showcases the Criterion 43 universal test system with a custom software interface, as well as composites testing fixtures and contact and noncontact extensometers.

Share

MTS Systems Corp. (Eden Prairie, Minn., U.S.) is providing a glimpse of its latest innovations in composite materials testing, such as testing fixtures and the company’s MTS Criterion family.

Designed for ease of operation, adherence to worldwide safety and ergonomic directives, and a multi-language MTS TestSuite TW software interface, the MTS Criterion family acts as a foundation for establishing and sustaining global, standardized test procedures.

The Criterion 43 universal test system comes complete with grips and an extensometer. The system features advanced controller technology, with a data acquisition rate of up to 5,000 Hz, which is said to be five times faster than the company’s previous controller. This improvement enables more precise measurement during a test and can be valuable when testing brittle or composite materials. An update rate of 5,000 Hz is also capable of providing improved measurement control for stiff specimens. In addition, cascade control is integrated into all MTS Criterion Systems, providing load and strain control as well as displacement control.

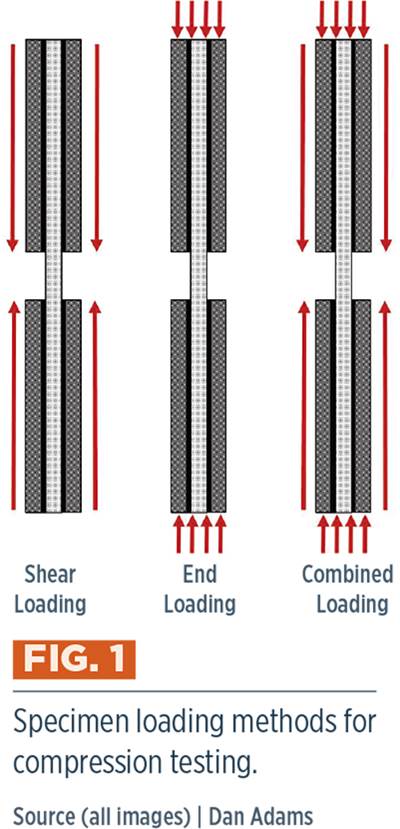

MTS is also sharing information about a wide array of composites testing fixtures, such as the following options designed for compression testing: the combined loading compression (CLC) composite fixture for testing per ASTM D6641; the modified celanese compression loading composite fixture for testing per ISO 14126; method 1 option A or the IITRI compression loading composite fixture for testing per ASTM D3410; and ISO 14126 method 1 option B.

Additionally, MTS is highlighting contacting and noncontact extensometers, including the MTS Advantage Video Extensometer (AVX). The AVX is designed to deliver the flexibility, accuracy and repeatability needed in applications where it is difficult to measure strain using conventional means. This video extensometer combines several features for measuring axial and transverse strain on composites.

MTS experts can provide more information about these products or any MTS solutions for dynamic testing, including the MTS Acumen electrodynamic test system, MTS Landmark and Servohydraulic test system, plus, its high-rate, high-force, axial-torsional and planar biaxial test systems.

Related Content

-

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

-

Optimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

-

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Related Content

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreOptimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreOptimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

Read MoreRead Next

Instron introduces 3400 and 6800 Series universal testing systems

New high-force floor models range up to 300-kilonewton force capacity, with a host of new features covering user safety, comfort, repeatability and long-lasting service life.

Read MoreOptimum unidirectional compression testing of composites

Dr. Daniel O. Adams, a professor of mechanical engineering, the director of the Composite Mechanics Laboratory at the University of Utah, and VP of Wyoming Test Fixtures Inc. (Salt Lake City, UT, US) discusses the complex relationship between composite tensile and compressive properties, why that makes it necessary to perform both tension and compression testing, and how best to perform the latter.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More