GFRP rebar replaces steel in parking garage

Composite rebar in replacement concrete slab the key in life-extending and less-costly structural rehabilitation project.

Engineering Challenge:

Rehabilitate a two-way reinforced concrete slab parking garage, replacing a steel rebar-reinforced floor slab with an alternative design that combats corrosion and extends building life.

Design Solution:

A corrosion-free composite rebar-reinforced floor slab, based on a lab-tested glass fiber-reinforced polymer rebar-specific punching shear equation, which performs like a steel-reinforced slab at a lower cost.

The early deterioration of concrete due to the corrosion and failure of steel rebar has been well documented in this magazine (click on “A hidden revolution: FRP rebar gains strength" under “Editor's Picks,” at top right). Conventional repairs could cost billions. Unrepaired structures, however, can cost lives. In Ville St. Laurent, a suburb of Montréal, Québec, Canada, a multistory concrete parking garage partially collapsed and killed a resident in November 2008. In the wake of this and a number of nonfatal parking structure collapses, the Canadian government teamed with the Natural Sciences and Engineering Research Council of Canada (NSERC) and other engineering partners to investigate ways to combat corrosion and improve multistory parking garage design.

Dr. Brahim Benmokrane, the NSERC research chair professor for the use of composites as concrete structure reinforcement at the University of Sherbrooke (Sherbrooke, Québec), headed the effort to determine the cause of the Montreal parking garage collapse. “Parking garages are tough environments, with high humidity and salt used in the winter months,” he says. “Reinforcing concrete with FRP bars would extend the life of a structure to 100 years or more, compared to steel-reinforced concrete, which needs major restoration after 25 years.”

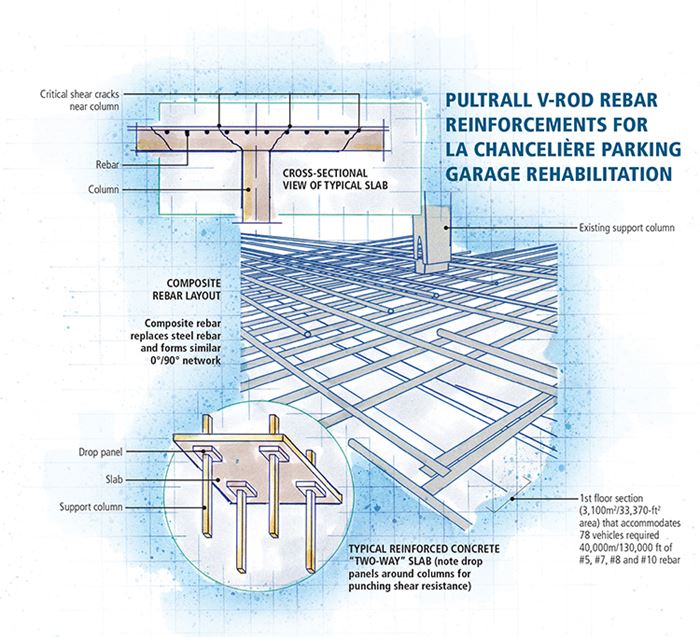

The issue: Punching shear failure

Concrete parking garages typically employ two-way structural slabs. One-way slabs (e.g., bridge decks) experience flex in only one direction; two-way slabs flex in two directions and require different design approaches. Usually, they are constructed in one of three ways: 1) a flat plate simply supported on a grid of columns; 2) a flat plate supported by columns that have areas of increased thickness, called drop panels or column capitals, directly under the plate to increase shear capacity at the column/plate intersections; and 3) a flat plate supported by beams that rest on columns.

A failure like the one in Montreal can occur when critical shear cracks start to form at 45° angles close to a supporting column (see drawing). Engineers often add shear reinforcement details, or curved stirrups, around support columns to help counter shear cracking, and if the steel rebar is in good condition, such cracks won’t affect serviceability as long as enough uncracked concrete remains and the aggregate is large enough to maintain aggregate interlock (load transfer and alignment) at the crack interface. That said, the Canadian parking garage building code forbids shear cracks that allow water ingress because it hastens rebar corrosion and allows water to drip on cars below. Ultimately, steel rebar corrosion causes a loss of bar cross-sectional area and, thus, reinforcement strength. This leads to excessive sag of the slab around the column and, in effect, causes the column to punch upward through the slab.

Although replacing steel rebar with GFRP appears to be an easy fix, Benmokrane echoes many civil engineers (e.g., engineer Larry Bank’s commentary in “FRP rebar: Shear reinforcement and detailing” under “Editor's Picks”) when he cautions, “The elastic modulus, ultimate strength and bond characteristics for FRP bars are quite different from those of steel bars, which affects the design of the reinforced concrete slab.” GFRP rebar has up to three times the tensile strength of same-diameter steel, but its shear capacity and modulus of elasticity are lower, explains engineer Mathieu Champagne, VP of sales and marketing at Pultrall Inc., a Thetford Mines, Québec-based supplier of GFRP rebar. “The modulus of elasticity for commercially available glass bars is 20 to 35 percent of steel, and for carbon fiber bars, 60 to 75 percent of steel.” For this reason, punching shear equations for steel-reinforced, two-way slab designs can’t be applied directly to FRP-reinforced versions, says Benmokrane. “We had to develop a punching shear capacity predictive equation for GFRP bars, since none existed in design guides or codes,” he points out, adding, “We wanted an optimized design that also satisfied strength and serviceability requirements.”

With that in mind, he and his research team at Sherbrooke designed an experimental study using 30 full-scale flat slab prototypes to compare steel to GFRP rebar systems, with and without additional shear reinforcement. The slab thickness was 200 or 350 mm (8 or 14 inches), with various concrete strengths. The columns were square in cross-section, either 300 or 450 mm (12 or 18 inches) on each side, and extended beyond the top and bottom of the test slabs. Bar types, diameters and reinforcement ratios (the area of the bars compared to the slab cross-sectional area) also varied from sample to sample. An actuated monotonic load cell was positioned directly under each column, with steel anchor bars at the edges of the slabs to hold them in place while the actuator applied load to failure.

During each test, Benmokrane reports, flexural cracks were observed first, and they radiated outward from the column toward the slab edges. This was followed, at higher loading, by circumferential cracks that connected the radial cracks. Increasing the GFRP reinforcement ratio from 0.71 to 1.62 percent raised the punching shear capacities at failure significantly. Lower strains in the reinforcement and smaller slab deflections also were observed. “The test results of the prototypes provided a clear overview of the structural behavior of the FRP reinforcements compared to steel, particularly the lower shear capacity and modulus of elasticity,” he asserts. That clarity enabled him and his graduate students to calibrate a new punching shear equation for GFRP rebar that is now incorporated into the Canadian Standards Assn. (CSA) Group (Mississauga, Ontario) concrete construction publications CSA S806-12, Design and Construction of Building Structures with Fibre-Reinforced Polymers, and CSA S413-07, Parking Structures.

Optimizing slab design with composites

With new punching shear design guidance in hand, Benmokrane proceeded in 2010 to use GFRP reinforcement in one portion of a large city-owned parking garage that was undergoing rehabilitation at Québec’s city hall. “We needed a pilot field implementation to verify our equation and design assumptions in a real flat slab structure under service conditions,” he says.

Champagne explains that one section of one floor, a 340m2/3,660-ft2 area, was rebuilt with 8,800m/28,870 ft of #5, #6 and #8 Pultrall V-ROD rebar, pultruded with high-modulus E-CR glass rovings sourced from many suppliers and wet out in a bath with vinyl ester formulated with proprietary additives and fillers. Champagne says the fiber volume of 65 percent (>80 percent by weight) and the wetout method combine to make V-ROD highly resistant to the effects of concrete alkalinity. The bars are coated inline with a sand mixture to create a rough surface that optimizes the rebar/concrete bond.

Optical fibers with Fiber Bragg grating sensors were attached to the GFRP rebar within the test area and monitored along with similar sensors on adjacent steel rebar. During the year-long monitoring period, “the GFRP bars behaved in a similar manner to the steel rebar in adjacent areas,” reports Benmokrane.

The pilot results gave the team confidence — with financial support from Québec City, the NSERC and others — to rehabilitate a second city-owned garage, La Chancelière. The replacement slab for the garage’s entire first level, a 3,100m2/33,370-ft2 area that accommodates 78 vehicles, was designed by EMS Ingénierie (Québec, Canada) and reviewed and validated by Benmokrane and his team, assuming high-modulus Grade III Pultrall rebar. An analysis was done, using fe-safe finite element and fatigue analysis software from Safe Technology Ltd. (Sheffield, U.K., and Livonia, Mich.). Service loads were assumed as 6.15 kPa (dead load) and 2.4 kPa (live load) when bending moments were calculated in the two slab directions (parallel and perpendicular to the column rows).

For the build, Pultrall provided 40,000m/130,000 ft of rebar, including #5, #7, #8 and #10 sizes, with #7 (22-mm/0.875-inch diameter) in the majority at 37,883m/123,120 ft. Two reinforcement mats, upper and lower, were installed. Holes were drilled into the existing columns, and GFRP rebar was inserted and doweled (glued in) to tie the mats to the columns. Shear reinforcement around the columns was not required, says Benmokrane, because 150-mm/6-inch thick drop panels were added at the top of each column to increase the punching shear strength of the slab.

A major consideration, adds Benmokrane, was fire performance: Canadian guidance CSA S806-12 mandates that the concrete cover over composite rebar must prevent it from reaching critical temperature (usually 250°C/482°F, the temperature at which the rebar loses 50 percent of its tensile strength and can no longer support applied load) for at least two hours. “We did a study with more than 100 samples, at temperatures up to 400°C [752°F], and found the critical temperature for their GFRP rebar was actually 325°C/617°F,” he reports. “This allowed us to use a thinner concrete cover for this project, saving weight and cost.”

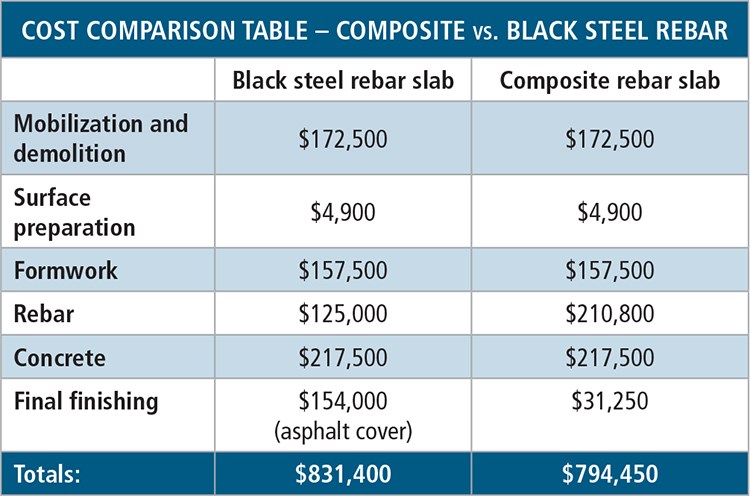

Less expensive than black steel bars

Remarkably, the composite rebar slab rehab actually cost less than an equivalent steel solution (see “Cost Comparison Table”). After concrete is cast over steel rebar, a waterproofing membrane and a 65 mm/2.5-inch thick layer of asphalt that are typically placed over steel-reinforced concrete to protect the concrete and steel from moisture ingress weren’t needed. The lack of asphalt and the low-weight of the GFRP rebar reduced slab weight, Champagne adds, noting that as a result, “we didn’t have to strengthen or wrap the existing building columns.” Ongoing monitoring shows no issues, with strain well below the minimal 2,000 microstrain target.

“This is a huge advancement for the composites industry,” concludes Benmokrane. “The structural performance … has been as expected, without any major problems or unexpected results during service, based on in situ monitoring.”

Adds Champagne: “The beauty of GFRP rebar is that reinforced concrete designs can be optimized for best cost, with mixing of rebar grades, to maximize lifecycle cost and benefits.”

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreCompPair adds swift prepreg line to HealTech Standard product family

The HealTech Standard product family from CompPair has been expanded with the addition of CS02, a swift prepreg line.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreRead Next

FRP rebar: Shear reinforcement and detailing

This second column taken from my new book Composites for Construction — Structural Design with FRP Materials (published by John Wiley & Sons Inc., New York, N.Y.) focuses on the design of concrete members that have FRP main tension reinforcing bars and are subjected to transverse shear forces (Chapter 6) and FRP reinforcement detail design (Chapter 7).The flexural concrete members that fall into the scope of this column are slabs and beams.

Read MoreA hidden revolution: composite rebar gains strength

Fiber-reinforced plastic (FRP) replacing coated steel in more reinforced-concrete applications.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)