A hidden revolution: composite rebar gains strength

Fiber-reinforced plastic (FRP) replacing coated steel in more reinforced-concrete applications.

Concrete has long been used as a building material for its high compressive strength, good durability and low cost. However, its well-known Achilles’ heel is its brittleness and limited tensile strength. This was solved quite handily about a century ago by using reinforcing bars (rebar) of steel in the tension side of concrete structures. Steel rebar is functionally efficient and relatively inexpensive, so it does a good job in most cases. However, steel rebar has its own weakness: susceptibility to corrosion (oxidation) when exposed to salts, aggressive chemicals and moisture. As it corrodes, steel rebar swells and increases the tensile load on the concrete, which begins to crack and spall, creating openings that lead to further and faster deterioration of the steel and concrete. This necessitates costly repair and maintenance and, if allowed to progress far enough, it can compromise the structure’s integrity. Numerous coatings and penetrants have been introduced over the decades to help seal out moisture from concrete, and rebar itself has been upgraded with epoxy coatings or the use of stainless steel. But it isn’t always possible to prevent corrosion in the long term. Further, steel rebar’s penchant to conduct electrical and magnetic fields makes it undesirable in concrete specified for certain power-generation, medical/scientific-imaging, nuclear and electrical/electronic applications.

FRP value proposition

There are many reasons why fiber-reinforced polymer (FRP) rebar makes sense in some concrete structures. For starters, composite rebar won’t rust or corrode, so it’s ideal for periodic or long-term immersion in fresh water or brine in applications such as retaining walls, piers, jetties, quays, caissons, decks, pilings, bulkheads, canals, offshore platforms, swimming pools and aquariums. It’s also immune to road salt and other deicing chemicals, making it a more durable and less maintenance-intensive choice for roadways and bridges, parking structures, airport runways, Jersey barriers, retaining walls and foundations, curbs, parapets, and slabs on grade. Further, it offers broad resistance to a host of other chemicals found at wastewater treatment plants, solid waste sites, petrochemical plants, pulp and paper mills, pipelines, tanks, cooling towers and chimneys, as well as the alkaline environment of concrete itself.

Another advantage is that the tensile strength of FRP rebar is typically 1.5 to 2 times higher than steel, so it’s a good counterbalance to concrete’s high compressive strength. It also provides excellent fatigue resistance, making it suitable for cyclic loading situations (such those on roads and bridges). Moreover, composite rebar is one-quarter the weight of comparably performing steel. Here there are a number of practical benefits. There is less wear and tear on construction workers who must carry and install it and less need for cranes and other heavy-lifting equipment. It is easily cut with common cutting tools, without damaging saw blades. More rebar can be hauled per truckload without exceeding legal loading limits. For bridges and like structures, the higher strength-to-weight ratio provides either greater carrying capacity for a given structure or possible opportunities to reduce the size and weight of the entire structure. Composite rebar also is useful in weight-sensitive applications where soils have poor load-bearing properties, in seismically active locations or in environmentally sensitive areas where it is undesirable to move heavy equipment.

For electromagnetically sensitive applications, both glass (the most common composite rebar reinforcement) and polymer are inherently nonconductive, so they won’t transmit current, attract lightning strikes or interfere with the operation of nearby electrical devices. That makes it a safer choice in aluminum and copper smelting plants, nuclear power plants, specialized military structures, airport towers, electrical and phone transmission towers, manholes containing electrical or phone equipment, hospitals with magnetic resonance imaging (MRI) equipment and toll-road sensing arrays and collection booths. Because glass-reinforced composite is equally poor at thermal transmission, it can be helpful for maintaining climate control in buildings, patio decks and basements.

Although the initial cost of composite rebar is generally higher than standard steel rebar and is roughly comparable to epoxy-coated steel rebar, when considered on a lifecycle cost (LCC) basis, it can be quite economical — particularly for non-prestressed concrete applications subject to flexure, shear and compressive loadings that typically require frequent repair and maintenance or where there are other issues with metal. For all these reasons and more, composite rebar has slowly begun to gain share in the civil engineering market.

No regs, no progress

Composite rebar got its start in Japan in the 1980s, with carbon and aramid fiber reinforcements in thermoset matrices, and slowly spread to projects in Canada during the early 1990s, says John Busel of the American Composites Manufacturers Assn. (ACMA, Arlington, Va.). But it didn’t really take off, he recalls, until specifications were developed and published for composite rebar in the late 1990s. Busel, director of ACMA’s Composites Growth Initiative, was for 12 years the secretary and then the chair of the American Concrete Institute’s (ACI, Farmington Hills, Mich.) Committee 440 - FRP Reinforcement, during the time that group developed its groundbreaking specifications and design guide for FRP rebar.

“Coming up with products that aren’t supported by testing and research just doesn’t work with civil engineers,” explains Busel. “It takes a lot of data to convince them, and obtaining that takes time.” In view of that reality, Committee 440 was established in the early 1990s and took close to a decade to develop the first edition, published in 1999, updated in 2006, with another update due in 2012. “Now you have standards that architects, engineers, and contractors can put into their plans globally,” says Busel, noting that “the ACI 440.1R has proven to be one of the best-known and best-used specification guides in the world and was definitely worth all the work.”

“The ACI 440 has been an extremely dynamic and active association,” notes Busel’s long-time colleague Doug Gremel. “We haven’t discriminated against any research anywhere in the world. If we can take it and incorporate it into our codes, we do it.” Gremel — the director of Non-Metallic Reinforcing at Hughes Brothers Inc., a director of Hughes subsidiary Aslan Pacific Ltd. (both of Seward, Neb.) and management committee chair at Omaha, Neb.-based Composite Insulated Concrete Systems LLC — adds, “We have no pride of ownership when it comes to this knowledge.”

Despite this growing body of science and experience in the mid- to late 1990s, growth in the use of FRP rebar was slow. The first U.S. installation didn’t appear until 1996 in the McKinleyville/Buffalo Creek Bridge in Brooks County, W. Va. FRP rebar finally gained traction in North America after its inclusion in the Canadian highway bridge code, where it became the default solution for dealing with corrosion caused by Canada’s harsh weather. That, in turn, led to work by the American Association of State Highway and Transportation Officials (AASHTO) to develop specs for the use of glass FRP (GFRP) concrete decks and traffic railings. From that point, U.S. Department of Transportation (DoT) engineers and specifiers had their own design guide to go along with ACI 440. As a result, says Busel, Canada and the U.S. together now have almost 400 bridges with FRP rebar in some aspect of their construction. European installations are growing, but at a slower pace.

Gremel — whose employer, Hughes Brothers, is a global supplier of FRP rebar — says the standards form the objective framework for quality assurance. “We have to provide production-lot certs as evidence that any given ‘mill run’ of rebar meets or exceeds the properties called out in ASTM standards,” he says. “We’re doing tensile modulus and strain tests on every lot we run, just like the steel guys.”

The civil engineering community’s progress toward comfort with FRP rebar might be slow, but it has not discouraged the pursuit of new approaches to its manufacture that could, as the following examples indicate, make the next generation of composite rebar a much more attractive alternative to steel.

Hollow rebar

Nearing commercialization is HollowRebar, invented by engineering professors at Oregon State University (Corvallis, Ore.) and currently owned by Composite Rebar Technologies Inc. (CRT, Madison, Wis.). The product features a pultruded inner layer of vinyl ester resin with continuous glass fiber reinforcement and a hollow center. This hollow, continuously reinforced rod is covered with a discontinuously reinforced sleeve that is bonded to the bar as part of the continuous production process.

Because the company is busy extending its existing methods and design patents in the U.S. and elsewhere, CRT chairman Robert Gibson could not divulge the details of its manufacturing process, but he did say the proprietary process enables his company to “tailor the product’s internal and external diameters as well as change the sleeve material, giving us a lot of flexibility to meet application needs.” The composition of the outer sleeve can include any resin that is compatible with and will bond to the vinyl ester resin core, and it can be reinforced with chopped carbon, glass and/or basalt fibers. The continuous-glass hollow inner sheath does the work of carrying loads. The highly densified, discontinuously reinforced BMC sleeve protects the inner layer from impact damage during storage, transport, and installation; acts as a barrier layer to protect the whole bar from microcracking and hence moisture intrusion (since concrete’s alkalinity can degrade glass); and also provides texturing options, e.g., helical deformations that increase bonding to concrete and offer additional possibilities as a “screw-on” attachment method for various connectors and anchors. The two layers are bonded mechanically and chemically and yield very high tensile strength. According to Gibson, preliminary testing has come back with values in excess of 160 ksi/113 kgf/mm2 for HollowRebar, compared to specifications for roughly weight-comparable #4 solid composite rebar (a 0.50 inch/13 mm diameter by 0.20 inch2/1.3 cm2 cross-sectional area) at 100 ksi/70.3 kgf/mm2 and 60 ksi/42.2 kgf/mm2 for steel rebar. Gibson says that HollowRebar’s tensile-strength advantage, partly a function of its comparatively larger diameter, increases as the diameters and comparable weights of hollow and solid composite bars increase because the tensile strength per unit of cross-sectional area declines as the diameter of solid FRP rebar increases. He says the tensile strength differential may lead to new ways of using FRP rebar, allowing more economical use of building materials while providing greater strength and durability. The hollow rebar can be up to three times stronger than steel but weigh roughly 75 percent less.

Further, the hollow core can be the conduit for electrical wiring or fiber-optic cable, enabling data or voice transmission, or it can house smart sensors for structural health monitoring. It might be used in climate control, for example to circulate heating fluids to keep bridge decks from freezing. Also, the hollow core provides the potential to connect one section of hollow rebar to another, which could speed installation and open up even more uses. Further, bends can be molded into the hollow rebar during initial production to meet specific geometries needed at a given site.

The company has refined the product design that was originally developed by the professors at Oregon State University (who still are involved in the company) and the proprietary production process, and it has built a custom machine to manufacture the hollow rebar. Additionally, CRT is actively working to validate performance of its product to ACI specifications. The product from the company’s pilot plant in Oregon has been sent out for independent testing to Antonio Nanni, professor and department chair of Civil, Architectural, and Environmental Engineering, University of Miami (Miami, Fla.), and Brahim Benmokrane, professor of Civil Engineering, Université de Sherbrooke (Sherbrooke, Québec, Canada), and chair of composites research efforts in concrete infrastructure and other civil structures for the Natural Sciences and Engineering Research Council of Canada. Gibson claims that the test results, so far, significantly exceed ACI published standards for composite rebar.

As part of its preparation for commercial production in 2012, CRT has partnered with pultruder Teel Plastics (Baraboo, Wis.) to enable additional product development and a faster ramp-up for the launch. By starting off with a contract producer, Gibson says the company can get to market faster, but it is already considering licensing the technology for other geographies.

Although the civil engineering community has been slow to adopt composite rebar, Gibson says that is beginning to change as engineers look beyond front-end costs. “Typically, the cost of steel rebar represents about 5 percent of the total cost of a concrete structure or paving project, and that percentage rises a bit when switching from steel to composites,” he notes, but he points out that “the failure of steel rebar leads to the need to replace the entire project, and that’s just bad economics when you have better technology that effectively doubles the use life of a structure for an incremental increase in cost. In such a scenario,” he argues, “you simply can’t afford not to make that change.”

New market for thermoplastics?

A notable trend is the scramble to develop fiber-reinforced thermoplastic offsets to established thermoset FRP rebar. Several companies (each declined comment for this article) are reportedly working with a variety of technologies that range from thermoplastic tapes and fiber winding to pultrusion of basalt fiber-reinforced thermoplastics. It is possible that the basalt/thermoplastic product could be produced in exceedingly long lengths and wound onto large spools at or near large civil engineering projects (e.g., sizeable buildings or long stretches of concrete pavement). This would enable crews to lay the rebar out in continuous sections with fewer breaks or splices than are necessary with steel rebar.

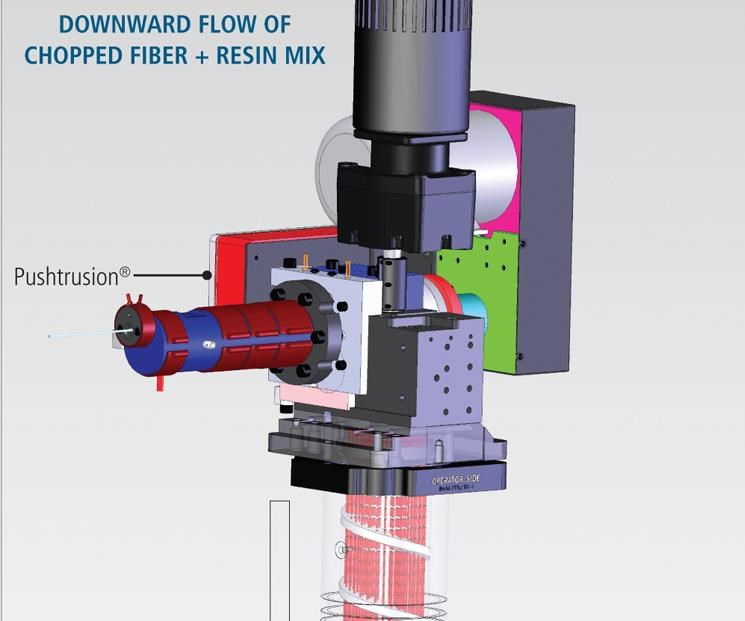

Only one developer was willing to talk about its new fiber-reinforced thermoplastics technology. Stephen Bowen, president of PlastiComp Inc. (Winona, Minn.) and the inventor of the patented and trademarked Pushtrusion process, revealed that a new patent was issued on Aug. 9 for his newest process innovation, which builds on five previous patents related to the Pushtrusion process. The machinery joins a continuously reinforced tension member to a discontinuously reinforced wrap that complements the tension member.

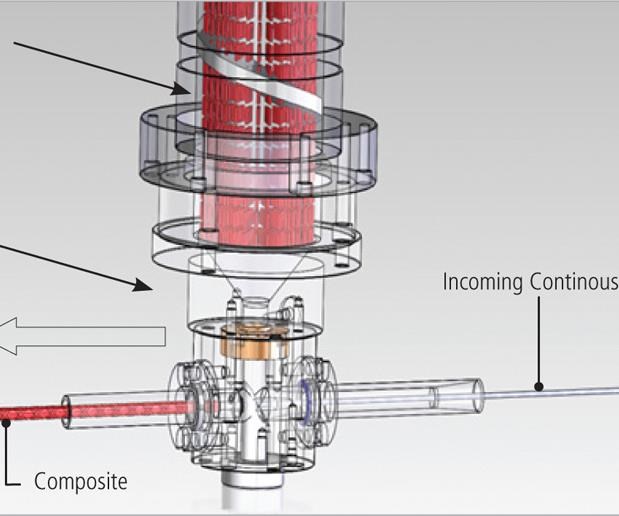

The two-layer molding process begins with Plasticomp’s Pushtrusion process, where continuous fibers are pulled into a stream of high-pressure and fast-moving molten resin. A rotary cutter, positioned in the flow path, is programmed to cut the fiber/resin mix into shorter lengths. Further downstream, a mixing screw combines the chopped fibers and resin into a consistent molten and extrudable compound. Typically, this compound would be used in a conventional injection or compression molding process. But in this case it is injected into a cross-head die. There, continuous fiber strands are pulled through the die where they are first impregnated with resin (via a conventional pultrusion), and, immediately thereafter, is encased in the molten compound created by the Pushtrusion process, which forms a discontinuous fiber-reinforced resin sheath. The resulting composite can be cut to specified lengths or spooled to permit onsite cutting.

In one of its uses, this new process reportedly forms a concrete-reinforcing technology that not only delivers all the benefits of fiber-reinforced thermoset rebar, but also addresses some of its practical deficiencies. Thermoplastics, for one, resist impact, microcracking and fatigue better than thermosets. Moreover, with a thermoplastic matrix, the finished rebar could be reheated and shaped or bent at a construction site, greatly reducing the number of rebar shapes that need to be ordered and inventoried for a job and cutting the cost of procuring unusual or custom shapes.

Here, the sheath makes a significant contribution. During initial bending trials with rebar made with continuous axial fibers only, the fibers on the bend’s outside radius tended to relocate to the inner radius during the melt phase, because tension on them increased as the rebar was bent. “This takes strength from the outside of the bar where you really need it. And of course, if you just use discontinuous reinforcement, you’ll never get the strength and stiffness you need,” Bowen explains. The discontinuous fibers in the sheath, however, ‘slip’ in relation to one another under tension during the melt/bend process. As a result, the fibers maintain a more symmetrical cross section. Further, the outer surface can be designed to incorporate dimples, cross-hatching, ribs, corrugations or other features that added roughness to increase mechanical bonding and pull-out strength when it is encased in concrete.

The thermoplastic offers two other advantages that are not yet available with thermosets: the opportunity to use recycled resins (such as bottle or CD scrap) and end-of-life recyclability. Perhaps the greatest potential benefit of thermoplastic rebar, however, is the speed at which it can be produced. The time the thermoset requires to crosslink is eliminated, and the rebar is produced in a single step. The potentially lower cost could make it more competitive with conventional steel and much less expensive than epoxy-coated and stainless steel rebar.

The patent allows for a broad choice of thermoplastic matrices (e.g., polypropylene, polyamide or thermoplastic polyester) and reinforcing fibers (e.g., glass or carbon) to meet the specific needs of a given application. As a result, Bowen says, concrete structures can shed extra sectional thickness. “Often, as much as 4 inches [101 mm] of concrete is added as a barrier to moisture ingress and to prevent subsequent corrosion of metal rebar. But with thermoplastic rebar, there would be no need for all that extra concrete, and the ensuing weight reduction opportunity could lead to large concrete structures with amazingly slim profiles,” he adds. “By integrating both continuous and discontinuous reinforcements, you really get the best of both worlds and achieve unprecedented control of the composition and construction of thermoplastic rebar.”

Bowen says that no one is currently testing the invention, and Plasticomp’s preference is to find a partner. “We’re an enabling company. We’re looking to license or sell our IP [intellectual property] to a big company that’s already a player in this segment.”

It is unclear whether reinforced thermoplastics will achieve performance and cost figures good enough to make then viable alternatives to thermoset composites in the rebar market, but given the level of development activity, thermoplastics bear watching.

What the future holds

Busel believes that concrete reinforcement holds great opportunities for composites, but he acknowledges that the use of FRP rebar in roads and bridges (its bread-and-butter applications to date) has been slow to get going. Progress may continue to be slow due to recession-related budget shortfalls. In the U.S., a transportation safety bill (Safe, Accountable, Flexible, Efficient Transportation Equity Act: A Legacy for Users, or SAFETEA-LU) is stuck in Congress, awaiting reauthorization and funding. It remains to be seen what inroads FRP rebar will make in the short term if federal funds aren’t available. “Only certain projects will get done, and everything else will be shelved,” Busel predicts.

“In the meantime, the ACMA is working with members of Congress and others in industry to develop lifecycle costing data for jobs funded by the DoT,” he reports. Historically, project developers and supervising agencies are reluctant to reveal their cost data and perform the analyses necessary for an LCC study. “If that’s not mandated,” Busel notes, “it just doesn’t get done.” But when those data are available, he believes that greater transparency will foster confidence in the composite rebar products among civil engineers and give those who make composite rebar “an even chance” to get their products specified.

If newer generation composite rebar can add a price advantage to its other benefits, then it will stand a much better chance of being specified in higher volume. That’s both a challenge and an opportunity for the whole composites industry to embrace.

Related Content

Pultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreRead Next

Composite Rebar Speeds Tunneling Operations

Pultruded replacement for steel reinforcement in concrete clears path for more efficient use of boring machinery.

Read MoreCOMPOSITES AND CONCRETE

The benefits of composite materials are well established in concrete reinforcement and construction.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)