The Mighty House is a prefabricated, 3D-printed housing unit that startup Mighty Buildings says can be built in less than a week. Future, multi-story Mighty House concepts will be built from continuous fiber-reinforced composites. Photo Credit, all images: Mighty Buildings

The recipient of the 2020 CAMX Unsurpassed Innovation Award, Mighty Buildings Inc. (Oakland, Calif., U.S.) was founded in 2017 with the goal of disrupting home construction using large-format 3D printing, advanced materials and automation.

“We observed that, after massive disruption going on in other sectors, home construction in the U.S. was still using largely the same technologies and processes we have been using for decades and, in some cases, centuries,” says Sam Ruben, chief sustainability officer (CSO) and one of the company’s four co-founders. He adds that traditional home construction methods “are often labor-intensive, materially wasteful and energy-inefficient.”

This was particularly evident in California, which, as its population has grown, has faced a long-standing housing shortage and lack of affordable housing for low- to middle-income residents. In August 2020, the average price of a single-family home in California reached a record $706,900.

At the beginning of 2017, California changed its state regulations to encourage the construction of accessory dwelling units (ADU) — standalone housing units built on the same property of a house or other primary dwelling, which can be used for guest or office spaces, or as small, affordable living spaces. Seeing this new regulation as an opportunity, Mighty Buildings’ founders applied to startup accelerator Y Combinator (Mountain View, Calif., U.S.). Accepted for the Winter 2018 cohort, the newly formed Mighty Buildings company began to leverage the founders’ combined experience in 3D printing (CTO Dmitry Starodubtsev), business (CEO Slava Solonitsyn), robotics and automation (COO Alexey Dubov) and sustainability and housing policy (CSO Sam Ruben) to develop the Mighty Buildings team and technologies.

“From the beginning, our vision has been to develop a material and technology that will allow us to unlock the productivity needed in construction to address the housing affordability crisis,” Ruben says. “We developed [our] material and printing technology after recognizing the need for a new way to build, in order to address the lack of efficiency in construction that has led to a global housing crisis.”

Mighty Mods and Houses

Originally operating out of 7,500 square feet in a shared warehouse in Redwood City, at the end of 2019 Mighty Buildings moved into a 79,000-square-foot renovated coffee warehouse in Oakland, 50,000 square feet of which is manufacturing space. Mighty Buildings operated in stealth mode for its first few years, focusing, Ruben says, on initial funding, technology development, building a certification roadmap and bringing the first products to market. The company emerged from stealth mode in August 2020 and hit the ground running. As of early December, Ruben reports that nine homes, or ADUs, have been built — six installed at their final sites and three more in production — with more than 20 additional contracts lined up.

Currently, Mighty Buildings constructs its housing solutions, like the pictured Mighty Studio accessory dwelling unit (ADU), and sells directly to consumers in California. Ultimately, the company plans to sell its production as a service platform around the U.S. and globally.

Ruben says that ADUs are the company’s initial focus to demonstrate the technology, a growing market “with streamlined permitting, making it a perfect market to demonstrate the viability of our technology for the market.” Currently, Mighty Buildings offers six models: four smaller “Mighty Mods” ranging from a 350-square-foot studio to the 700-square-foot Duo B/I, which are built at the company’s production space and then installed on-site via crane; and three, two- to three-bedroom “Mighty Houses” which are built as panels that are shipped and assembled at the construction site. Custom projects can also be accommodated for larger projects with developers/builders.

“Our modular units arrive fully finished with everything needed to move in, including washer/dryer, fridge, dishwasher, etc.,” Ruben says. He adds that, depending on the model, installation usually only takes a day or two, with additional on-site assembly typically completed within a week, compared to the months-long process of building a home using traditional on-site construction methods.

Prices for a turn-key Mighty Building structure range from $183,750 for the 350-square-foot Mighty Studio model to $409,500 for the 1,440-square-foot, three-bedroom, two-bathroom Mighty Cinco model.

Innovation and automation

According to Ruben, the team was inspired by innovations in UV-curable resins — Solonitsyn and Starodubtsev had originally met through a project developing 3D printing “pens,” which deposit small amounts of a resin gel onto a surface and then solidify it with UV light. The idea behind Mighty Buildings was to expand this type of product to a much larger scale and transfer it to the construction market, to “not only speed up the construction process and improve the sustainability of the process, but to also open up new ways of designing buildings,” Ruben says.

The result is a printing material called Light Stone Material (LSM) and a 3D printing process called Photo Activated Component Extrusion (PACE). “We have created a proprietary printing material and technology which allow us to UV cure an extrudable gel that cures quickly enough to be able to support its own weight, unlocking the ability to print unsupported spans and organic shapes,” Ruben says.

UV-curable resin

The original version of LSM is an unreinforced thermoset resin (Mighty Buildings calls it a composite, in this case meaning a mixture of resin with a UV initiator and other proprietary materials) that Ruben says is “similar to DuPont’s Corian composite material, but higher performance.” This unreinforced resin enables building single-story buildings and ADUs, but ultimately, Mighty Buildings plans to go bigger and taller — up to 3-5 floors and taller — with the help of fiber reinforcement.

Pictured here, Mighty Buildings’ PACE 3D printing system can fully 3D print all structures for a modular ADU in one print.

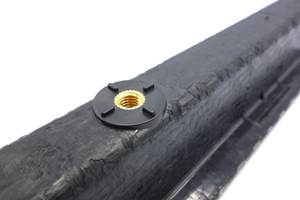

A version of LSM reinforced with continuous glass fiber has been developed, and Ruben says that internal testing has shown that 3D-printed structures made with this material are “able to achieve a maximum ultimate load similar to that of a comparably-sized, steel-reinforced concrete beam, with more than four times less weight and an ultimate tensile strength that is nearly 20 times higher.” LSM is also water and fire resistant, highly energy-efficient and is said to be the first UL-certified 3D-printed building material.

The higher strength will also enable Mighty Buildings to scale up into taller structures and buildings without the need for support structures. “We can print the roof as well as the walls and floors, opening up a new era of design possibilities,” he says. Mighty Buildings expects the reinforced composite material to pass requisite UL 3401 certification testing within the next year or so, to meet the company’s goal of launching multi-story, multi-family buildings in 2022.

3D printing and assembly

Production of each prefabricated building requires, in broad strokes, four steps: 3D printing, quality control, post processing and assembly. Automation plays a large part each step of the way. In addition, currently, Mighty Buildings is working with MSC Software (a division of Hexagon, Newport Beach, Calif., U.S.) to develop its own digital simulation and modeling platform. “We’re working toward 100% digital fabrication,” Ruben says, “and plan to use this platform to simulate every step of production before the build to reduce production costs and speed the process, eliminate quality control issues and enable late-stage changes.”

The PACE 3D printing process is designed for large parts, zero waste and speed. It involves extrusion of an LSM gel at room temperature and polymerization via UV light at the end of the printhead. The PACE system boasts a print volume of 11 x 26 x 13 feet: “We’re limited more by overland transport size than 3D printing volume of the machine,” Ruben says.

With the help of robotic arms, cured parts are inspected via 3D scanning and thermography, and then each structure is moved into a robotic finishing cell for post-processing. Depending on the project, this may involve milling the exterior surface to simulate a stone-like or brick finish, spraying on paint, and pouring polyurethane insulation foam layers into wall interiors.

“Currently, we are automating 40% of the construction process, and ultimately will be at 80%,” Ruben says. “The goal is to maximize the value of the human labor, which is in short supply, and in the end to actually create more [human] work overall by increasing the total number of units built on a massive scale, while making for less work per unit. In doing so, we hope to not only increase efficiency but to attract a new generation of workers to the construction industry.”

Finished modules are then transported and assembled at the construction site. Mighty Buildings’ current process takes about two to three weeks start to finish to build a house. The company’s ultimate goal, Ruben says, is to build an entirely 3D-printed module from start to finish in less than a week.

Long-term goals and expansion

Currently, all ADUs are sold direct-to-consumer, but a longer-term goal is to sell the process, as a “production as a service” platform, so that homes can be built closer to demand in different areas around the U.S. and globally. Citing Mighty Buildings’ relatively small urban location as an example, Ruben says that the goal is to enable building of distributed “Mighty Factories” with small footprints in existing warehouse spaces, using and training a local workforce. “One of our goals is to train the next-generation construction workforce,” he says. The company’s first commercial agreement has been made with a developer in southern California to build apartments and single-family homes.

Related Content

Hybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.

Read MoreOptimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

Read MoreRobotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreRead Next

Winners for 2020 Award for Composites Excellence (ACE) announced

The 2020 Awards for Composites Excellence (ACE) recognized the University of Tennessee, TRB Lightweight Structures, University of Delaware, IYRS School of Technology and LyondellBasell for outstanding achievement and innovation.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)