Winners for 2020 Award for Composites Excellence (ACE) announced

The 2020 Awards for Composites Excellence (ACE) recognized the University of Tennessee, TRB Lightweight Structures, University of Delaware, IYRS School of Technology and LyondellBasell for outstanding achievement and innovation.

For the Design category, the Most Creative Application Award went to the University of Tennessee for UTK Filament Tower. Photo Credit: ACMA

On Sept. 24 the American Composites Manufacturers Association (ACMA; Arlington, Virg., U.S.) announced the winners for the Awards for Composites Excellence (ACE) sponsored by Composites One (Arlington Heights, Ill., U.S.). According to the ACMA, the ACE is a prestigious composites industry competition that recognizes outstanding achievement and innovation in design, manufacturing and market growth. The winning entries were announced virtually at the seventh annual Composites and Advanced Materials Expo (CAMX).

Each category with its designated winner is categorized below.

Design

In the Design category, the Most Creative Application Award went to the University of Tennessee for UTK Filament Tower.

The UTK filament tower was the first composite structure featured at Exhibit Columbus (Columbus, Ohio, U.S.), a biennial event where designers create outdoor installations and experiences. A team of 23 students, faculty and staff used a nine-axis robot and a novel coreless filament winding technique, which eliminated the need for a surface mold, to construct the 30-foot lattice tower. It featured 3D-printed composite bases and 27 composite components, each weighing between 5-30 pounds. and measuring 3-8 feet in length. The project explored computational design and robotic fabrication of composite structures for architectural applications, highlighting the aesthetic qualities of carbon and glass fiber.

Manufacturing

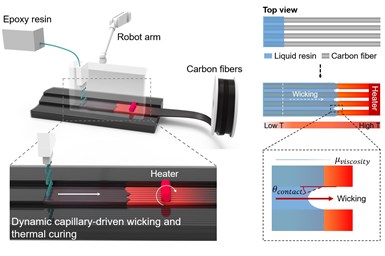

In the Manufacturing category, the Equipment and Tooling Innovation Award went to the University of Delaware for 3D Printing Continuous Carbon Fiber/Thermoset Composites.

The University of Delaware won in the Manufacturing category for its LITA 3D printing system.Photo Credit: University of Delaware

The University of Delaware Composite and Additive Manufacturing (CAM) Laboratory has developed a localized in-plane thermal assisted (LITA) 3D printing technique to fabricate continuous fiber-reinforced thermoset composite parts. The 3D printing technique is based on a robotic system consisting of printing head, liquid thermoset resin dispenser and heater. This 3D printing technique allows thermoset polymer liquid with a controllable viscosity and degree of curing to enable its fast and near-simultaneous infusion and curing to implement in-situ solidification of composites into arbitrary shapes. A wide range of thermoset polymers and fibers (e.g., carbon, glass and Kevlar) could be applied.

The Manufacturing category also features the Materials and Process Innovation Award which went to TRB Lightweight Structures Ltd. (Huntingdon, U.K.) for Fast Press Cure, A Disruptive High Volume Composite Manufacturing Method..

TRB has developed a fully automated and vertically integrated process to unlock composites at scale. Photo Credit: ACMA

TRB has developed a fully automated and vertically integrated process to unlock composites at scale, resulting in the manufacture of complex components in a fraction of the time of traditional hand layup. It works with carbon fiber, glass, hemp and other composite fiber materials and can incorporate EMI shielding, thermal insulation, high voltage insulation in the layup process, to enable the right material mix and structure for a wide variety of components. This innovation means that for the first time, composites can meet the cost, velocity and quality requirements of the electric.

Market Growth

In the Market Growth category, the Composites Sustainability for Market Growth Award went to LyondellBasell (Houston, Tex., U.S.) for Composite Manhole Covers Solve Iron Problems.

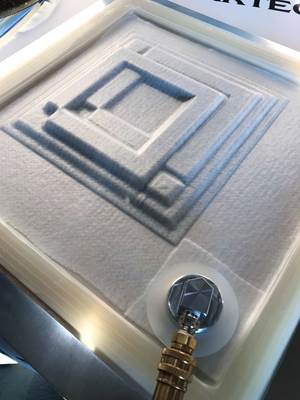

LyondellBasell and Composite Access Products (CAP) collaborated to replace traditional materials like metal and concrete used in manhole applications with composites. Photo Credit: ACMA

With rising construction activities worldwide, the manhole cover market is expanding. Through the collaboration between LyondellBasell and Composite Access Products (CAP; McAllen Tex., U.S.), composite solutions are replacing traditional materials like metal and concrete used in manhole applications due to its superior properties like strength, corrosion resistance and molding capabilities. Through CAP’s compression molding process of LyondellBasell’s thermoset material, cost improvements and rapid production cycles are realized when compared to resin transfer molding (RTM) and other fiberglass (FRP/GRP) casting processes. This process enhances quality by reducing entrapped gas, ensuring a complete thermoset polymer cure, delivering fully impregnated fiberglass and eliminating many post-process operations.

Finally, in the Market Growth category, the Infinite Possibility for Market Growth Award went to the IYRS School of Technology (Newport, R.I., U.S.) for Heavy Lift Aerial Platform (HLAP).

The Heavy Lift Aerial Platform (HLAP) concept model has a range of applications from urban air mobility, commercial or military, including delivery of goods, observation, inspections, communications, search and rescue or cinematography. This multi-purpose unmanned aerial vehicle features a 29-pound primary airframe with an all-up flying weight of 61 pounds. The eight power units produce a load capacity of 103 pounds. The array of processes employed include: Direct tool CNC machining, prepreg fabrication, vacuum infusion, 3D printing and hollow form braiding. The three-year project has involved multiple generations of IYRS students engaged in CAD modeling, CNC operations and fabrication of various platform components.

IYRS School of Technology wins Market Growth category for the Heavy Lift Aerial Platform (HLAP) concept model. Photo Credit: ACMA

Related Content

VIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

Read MoreConcentrated smooth dispersion simplifies electrical conductivity applications

CAMX 2024: Total Resin presents Total Nanotüp, a concentrated dispersion of carbon nanotubes in a bifunctional reactive monomer for polyester, vinyl ester, melamine and acrylic resins.

Read MoreCAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

Read MoreReusable vacuum bagging solutions for composite applications

CAMX 2023: Smartech underscores its industrial reusable vacuum bagging products for reduced waste, easy debulking and the capability to be used for complex projects.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)