A new definition of composites?

Nucleation and control of crystallinity plus aspect ratio creates new plastic and ceramic composites with tailored performance.

As composites technology develops, so too should our understanding of what composites can be and what they can offer.

This blog originated from a press release that I received from IntegriCo Composites (Sarepta, La., U.S.), which manufactures composite railway crossties and construction mats. In looking at their press release and website, both of which focused on recycling and transforming plastic waste into sustainable, improved-performance end-products, I realized this was a 100% plastic technology. So, I wrote back and said, “your definition of composite does not match ours.” But I was wrong.

How a mixture becomes a composite

What is the definition of a composite?

A composite is two or more materials combined where each retains its unique identity (i.e., not alloyed) and contributes its own structural properties, enabling the resulting material to have superior performance.

I explained that while IntegriCo claims that its products are composites with superior properties, they are, in fact, an alloy — a melted amalgamation of plastics. There is no fiber reinforcement and not more than one identifiable material in the final product.

Brian Arkwood, chief technical officer for IntegriCo, begged to differ, explaining that IntegriCo’s products are a mixture of two or more types of materials that do retain a unique identity, designed and engineered through processing to deliver superior characteristics and performance. “Allow me to clarify,” he said.

Our process uses a mixture of HDPE (high density polyethylene) and LDPE (low density polyethylene), as well as polypropylene and polystyrene. This is by design, as each of these dissimilar polymers contributes to the overall characteristics of the end-product. We can manipulate and/or change the properties of the end-product by differing the ratios of each plastic and/or processing of the overall mixture. The varying plastics are not merely melted together, however.

Here is where this mixture becomes differentiated as a composite:

“The higher molecular weight (HMW) plastics that do not melt are interspersed through the continuous polymer of the plastics that are processed above the melt temperature. As this mixture cools, the plastics undergo the process of nucleation. The rate and process of nucleation is controlled by processing temperature, cooling rate and the subsequent loading of a nucleating agent. This agent is a chemical developed by IntegriCo and only used in our process.”

“As nucleation takes place, the overall crystallinity of the plastic mixture is manipulated and the HMW non-melt polymers are entangled amongst the polymer chains that are bonded covalently. The polymers are also manipulated via shear stress to reduce viscosity during molding to promote better interaction and entanglement of nucleated polymers with the non-melt polymers.”

Nucleation, crystallinity and controlling aspect ratio

For me, the key concepts here are nucleation (the beginning process of crystal formation), control of crystallinity (managing crystal formation) and manipulating the process to achieve a better interface between the entangled nucleated polymers and non-melt polymers. The last bit is really crucial for composites, because without a good interface between the different materials, there is no effective load transfer and no superior performance.

Also, remember that in the high-growth area of thermoplastic composites, the polymers offering higher mechanical properties as well as greater temperature and chemical resistance are semi-crystalline. Those semi-crystalline properties are achieved and tailored by managing the crystallinity, most typically via temperature control during processing.

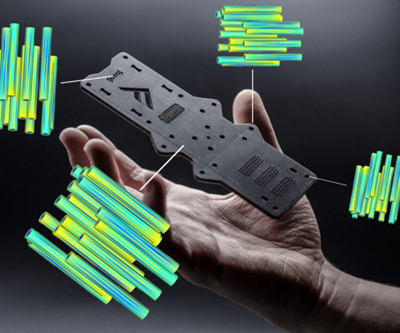

IntegriCo composite railway crossties offer a way to reuse plastic waste in a superior performance composite product, where elongated high-melt plastic reinforces a low-melt plastic matrix. SOURCE | IntregiCo Composites

Arkwood’s description also made me think of self-reinforced plastics (SRP), such as Pure, Curv, Armordon, Tegris and the most recent, the BIO4SELF project, which won a 2019 JEC Innovation Award. Typically, SRP composites are made by using a low melt temperature polymer (PE, PP or PLA biopolymer) and reinforcing that with a higher melt temperature fiber made from the same polymer. This use of high and low melt temperature polymers is exactly what IntegriCo is doing. So I asked Arkwood if the higher molecular weight (HMW) non-melt polymers he is using are actually appearing/forming/behaving like fibers?

“It enables some of the same benefit as fibers,” he said. “We change the aspect ratios of the HMW polymers within the polymer matrix to drive the properties of the product. Increasing or decreasing the HMW polymers, coupled with changes to other operating parameters, can have significant effects on plastic properties such as modulus of elasticity, modulus of rupture and hardness.”

Arkwood explains that IntegriCo can modify polymer ratios and operating parameters to meet specific customer needs. “We have documented this with destructive testing data and have met property-driven requests for customers including Union Pacific and the U.S. Army. The ratio of polymers — HMW to LMW and linear to non-linear or highly branched — plays a role in our products much like fiber reinforcement in other plastic composite products, by affecting the key performance properties of strength, stiffness, hardness and toughness.”

Sustainability

So, first point, IntegriCo does indeed provide an inspiration worth noting by the composites industry as our planet is being destroyed with waste. More than 90% of plastic becomes waste worldwide and more than 34 million metric tons of plastic are sent to landfills or incinerators each year in the US and Canada alone. IntegriCo is offering a real solution by recycling mixed rigid plastics and typically unrecyclable grades 3-7, which China stopped receiving in 2018. Plastic grades 3-7 are those harder to recycle as classified by the ASTM International Resin Identification Coding System (RIC) which identifies the constituent polymers and recyclability of all plastics. Grades 1 (PETE, PET) and 2 (HDPE) are highly recyclable, and 5 (PP) is starting to be recycled, while all other grades including 3 (PVC), 4 (LDPE), 6 (PS) and 7 (Other) are not currently recycled. Thus, IntegriCo is making a difference, diverting waste from landfill and engineering it into value-added composite products that last longer than alternatives, producing less waste over time.

Nano-CMCs

My second point is that technology is moving forward in what a composite is. I believe that is already impacting the advance of composites material science and I want to hopefully inspire further developments. What triggered this realization for me was Arkwood’s use of nucleation. I immediately recognized it from my recent research into nano ceramic matrix composites (nano-CMCs, see my July 2019 article on nanocomposites).

This is from a Nov 2017 article, “Polymer and ceramic nanocomposites for aerospace applications” :

“Nanocomposites are the materials of twenty-first century having an annual growth rate of 25% due to their multifunctional capabilities. … Due to the possibility of combining desired properties, nanocomposites are expanding their potentials in aerospace applications and in future space missions. … Nanofillers increase the nucleation capability by improving interfacial interaction with the polymer matrix.”

I can’t vouch for the 25% growth rate, but it is obvious nanocomposites offer a lot of potential. This text discussed nucleation of nanofillers. What was new for me was the development of nano-CMCs where a ceramic matrix is actually reinforced with not a fiber or filler but another ceramic, where the latter’s nucleation and crystallization are controlled to produce high-aspect ratio reinforcement.

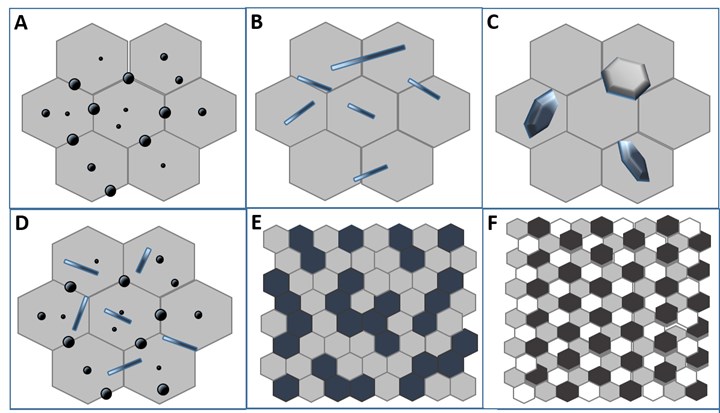

In my July 2019 feature on nanocomposites, I use an illustration from Paola Palmero’s 2015 article, “Structural Ceramic Nanocomposites: A Review of Properties and Powders’ Synthesis Methods” to show examples of microscale and nanoscale composites. A, B and C show a microscale (micronic) matrix reinforced with nanoparticles, nanofibers or nanoplatelets, respectively, while D has both rounded and high aspect ratio nanoreinforcements. However, E and F illustrate bi-phasic and multi-phasic nanocomposites, respectively, where the nanoscale ceramics are immiscible.

Fig. 1 Common micro/nano composite structures for ceramic materials.

SOURCE | “Structural Ceramic Nanocomposites: A Review of Properties and Powders’ Synthesis Methods” by Paola Palmero.

Palmero describes the in-situ crystallization of second-phases on the surface of matrix particles — in other words, the matrix is the first phase and another ceramic is the second phase — as one of the key processes involved in manufacturing ceramic nanocomposites. After crystallization, the size and shape of the ceramic crystals or grains are managed, which is crucial, as these determine the ceramic compositeʼs bulk properties. For example, elongated grains are known to have an in-situ toughening effect. Palmero notes that the ability to tailor the desired nanostructured features in these sintered composites is vital but challenging, mandating stringent process control throughout mixing, forming, sintering and densification.

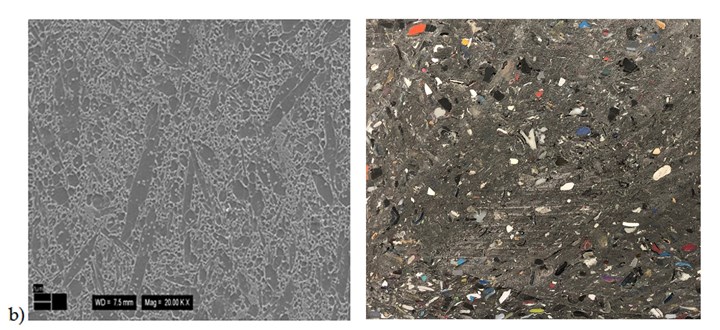

A similar illustration and discussion is seen in Fig. 6 in the Intechopen.com book, Physical and Metallurgical Characteristics of Fiber Reinforced Ceramic Matrix Composites. Section 9.1.2 discusses the microstructure of silicon nitride(Si3N4)/silicon carbide (SiC) nanocomposites, which are made by sintering (hot pressing). Their microstructure contains large elongated particles of β- Si3N4 (whiskers) which are surrounded by finer particles of β- Si3N4 with needle shapes. The scanning electron micrograph below from Fig. 7b shows this structure at 20,000th magnification.

These cross-sections of bi-phasic ceramic nanocomposites (left) and recycled plastic composites (right) are actually quite similar, even though they differ greatly from the cross-sections of conventional continuous fiber reinforced composites.

SOURCE | Figure 7, Section 9.1.2 from Physical and Metallurgical Characteristics of Fiber Reinforced Ceramic Matrix Composites by Zdeněk Jonšta, Evelyn A. Bolaňos C., Monika Hrabalová and Petr Jonšta (left) and cross-section of composite railway crosstie, IntegriCo Composites (right).

Benefits of bi- and multi-phasic composites

So why is this of benefit to the composites industry? Because material scientists are using this new definition of composites to achieve unique, tailored combinations of mechanical, thermal, electrical and ablative properties. For example, the Naval Research Laboratory (NRL, Washington, D.C., U.S) has developed silicon nitride, zirconium nitride and titanium diboride composites as well as methods to reinforce them with tough fibers. These refractory ceramics exhibit high strength, thermal stability and variable electrical and thermal conductivities that allow them to meet the demands of hypersonic vehicle components — something that organic polymer composites and even advanced metal alloys cannot do.

… these materials could also provide valuable solutions for planned space exploration … [and] open new avenues for fully biobased composites

NRL is also developing additive manufacturing technology that will incorporate nanostructures into these materials and further tune dielectric, thermal and electromagnetic shielding properties at a higher resolution than possible with currently available materials. Even if you don’t necessarily agree with the defense applications planned for these materials, they could also provide valuable solutions for planned space exploration and missions to Mars. But they may also open new avenues for fully biobased composites which offer not only high performance here on earth, but also the ability to do so sustainably and in a way that materials and end-products can be manufactured and recycled using less energy and resources.

I’m not suggesting that fiber-reinforced composites are exiting the stage or even fading. But as technology develops, so too should our understanding of what composites can be and what they can offer.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreRead Next

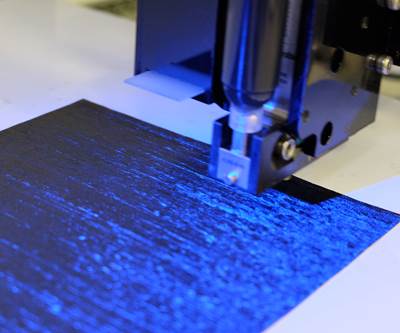

Magnetic 3D printing the next generation of tailored composites

Fortify uses magnetic fields and digital light processing to produce tailored microstructures for high-resolution, 3D printed composite parts — and enables the next generation of multiscale, multifunctional composite metamaterials.

Read MoreNanomaterials: Products, supply chain mature for next-gen composites

Development spans 3D and thermoplastic nanocomposites, nano-CMCs for hypersonics and nanomaterials safety and toxicity.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More