The promise of nanomaterials to deliver unprecedented mechanical properties, along with tailorable electrical and thermal conductivity for composites, has been heralded for decades. Because of their unique properties and tremendous surface area, nanomaterials have the potential to push product performance beyond current macroscale composites. Though nanomaterials such as graphene and carbon nanotubes (CNTs) are commercially available from a number of companies and websites, widespread application in composites is not as apparent.

Meanwhile, materials and terminology are rapidly evolving; CW provides a primer on current nanomaterials, as well as significant developments in new materials and the supply chain.

Nano landscape for composites

Nanomaterials may be metal, ceramic, polymer, carbon-based or from natural sources like cellulose. Nanomaterials form a composite when used to reinforce a polymer, ceramic or metal matrix, and they are typically classified by shape (morphology) as either particles, fibers or platelets (see “Nanomaterial types and definitions,” below). As the material decreases in size from micrometer (10-6 meter) to nanometer (10-9 meter), surface area increases so that the nanomaterial-matrix interface comprises more of the composite’s volume. This is why finished product property improvements of 20-50% can be achieved with one to two orders of magnitude less loading vs. micromaterials like carbon black and milled fiber. This is also why, just as the properties of a macrocomposite hinge upon mechanics at the fiber-resin interface, understanding and controlling the interfaces of a nanocomposite are even more important for managing material properties and performance.

However, the promise of nanomaterials has been hindered by difficulties in scaling up cost-effective manufacturing processes of high-quality materials with minimal flaws. In addition, achieving homogeneous dispersion of nanomaterials within matrices has been a challenge because of the tendency for nanomaterials to agglomerate. The latter can be overcome by functionalization of the nanomaterial surface. Common techniques, which are often combined, include modifying the electrical charge of the nanomaterial or matrix, modifying the pH or adding a surfactant.

The composites industry typically thinks of a nanocomposite as any matrix with a nanomaterial dispersed into it. However, microcomposites may be distinguished from nanocomposites based on the primary scale of the interfaces. Fig. 1 provides examples of various micro/nano composite combinations and interfaces. A micro scale (micronic) matrix is reinforced with nanoparticles, nanofibers or nanoplatelets, as seen in A, B and C, respectively, while a nanocomposite is differentiated as a matrix phase mixed at the same scale as the nanomaterial, as shown in E and F.

Fig. 1 Common micro/nano composite structures for ceramic materials. Micro/nano composite comprising micronic matrix with (A) rounded nanoparticles, (B) high aspect ratio nanoreinforcements, (C) platelet-like nanoreinforcements and (D) both rounded and elongated nanoreinforcements; (E) bi-phasic composite made by two immiscible ultra-fine phases; (F) multi-phasic composite made by three (or more) immiscible nanophases. Source | “Structural Ceramic Nanocomposites: A Review of Properties and Powders’ Synthesis Methods” by Paola Palmero, Nanomaterials (Basel). Jun 2015

2D nano to 3D multifunctional composites

Within the nano landscape, perhaps the most active region is that comprising 2D nanomaterials. The most popular of these is graphene, which has gained substantial popularity thanks to its extraordinary properties. Graphene is the lightest weight (0.77 mg/m2) and strongest known material (100-300 times steel), harder than diamond yet more elastic than rubber, with electron mobility 100 times faster than silicon, electrical conductivity 13 times better than copper and a very high surface area. Graphene appears able to bridge certain gaps in conventional property constraints. For example, when added to rubber, graphene can simultaneously increase tire grip and reduce wear. Formula 1 fans know from watching race cars swap between soft tires (high grip, less wear resistance) and hard tires (less grip, more wear resistance), that these two properties do not normally coexist. “Carbon black has been the normal filler for rubber in tires, but graphene offers a much higher performance at a much lower load factor, replacing 1-2% carbon black with only 0.01% of graphene,” explains Terrance Barkan, executive director of The Graphene Council (New Bern, N.C., U.S.), an industry resource and support organization.

Researchers have been intent on evolving these materials, synthesizing hundreds of 2D layered nanomaterials over the past decade from polymers, metals and carbon allotropes like graphene (see “Nanomaterial types and definitions”). These 2D nanomaterials can then be combined, stitched together, stacked and/or arranged to form an almost infinite variety of 3D architectures to create novel, multifunctional materials. Graphene and other 2D nanomaterials have been combined into 3D architectures with large pore volumes, low density, increased mechanical properties, high specific surface areas, rapid electron and mass transport (used in cooling very hot surfaces) as well as unique optical properties and photonics capabilities.

Early entrants move forward

NanoStitch vertically aligned CNT film products were introduced by N12 Technologies (Somerville, Mass., U.S.) in 2015. When interleafed in composite laminates, NanoStitch increases interlaminar shear strength (ILSS) by >30% and compression after impact (CAI) by 15%. CW reported in 2018 that N12 Technologies agreed to incorporate the 60-inch-wide, continuous CNT film production line at the University of Dayton Research Institute (UDRI, Dayton, Ohio, U.S.) as its second manufacturing facility. “We have now fully validated production operations in the Kettering, Ohio, facility,” says Christopher Gouldstone, N12 director of production development, noting the company still maintains its corporate and applications headquarters in Somerville. He says one of the biggest applications highlights for NanoStitch in 2019 is becoming the official composites technology partner for the Santa Cruz Syndicate World Cup Mountain Bike Team. “After a collaborative development process to implement NanoStitch into Santa Cruz Bicycle designs, the Syndicate is racing on impact-resistant NanoStitch-reinforced wheels this season,” says Gouldstone. “N12 continues to apply NanoStitch to improve impact, compression, shear and fatigue properties of composites for multiple markets including aerospace and consumer goods. We have also ramped up development for multifunctionality, using the high conductivity of vertically aligned CNTs for electrostatic grounding, strain sensitivity and surface heating.”

Thermoplastic nanocomposite replaces aluminum

Meanwhile, one of the first commercial thermoplastic nanocomposites was launched earlier in 2019 by Alpine Advanced Materials LLC (Dallas, Texas, U.S.). HX5 is a high-performance material designed to replace 6061 T6 aerospace-grade aluminum, improving performance while cutting weight by up to 50%. HX5 is being commercialized through an exclusive license from Lockheed Martin Corp. (Bethesda, Md., U.S.), where the product was developed as APEX (Advanced Polymers Engineered for the Extreme) and tested and proven in parts for aircraft, helicopters, amphibious transport vehicles, missiles, rockets and satellites.

“Alpine Advanced Materials has full access and global rights to the APEX technology for both military and commercial applications,” says Jon Bennett, vice president of corporate development for Alpine Advanced Materials. “HX5 can be machined, coated, painted, welded and adhesively bonded like metal, yet can be processed using injection molding.” Because Alpine is not currently permitted to share many details, CW has compiled a history of the material’s development from publicly available information.

Fig. 2 Thermoplastic nanocomposite brackets. This front view of a missile forward destruct bracket shows the benefit of injection molding with HX5 thermoplastic nanocomposite, reducing cost by 93% and weight by 15% com-pared to the aluminum baseline. Source | Alpine Advanced Materials LLC

According to Lockheed Martin’s 2013 APEX brochure, HX5 is compatible with the full palette of thermoplastic composites processes including compression molding, extrusion, thermoforming, automated fiber placement, filament winding and 3D printing. It also enables joining methods such as welding and overmolding. According to articles published from 2011-2016, development of the thermoplastic nanocomposite was overseen by Dr. Slade Gardner, now chief technology adviser for Alpine Advanced Materials and previously Lockheed Martin fellow in Advanced Manufacturing and Materials for Lockheed’s Space Systems Co. Gardner assembled a team of researchers that developed the formulation for APEX by 2008 and was prototyping parts for customers by 2009. The team began producing prototype spacecraft hardware in 2010, including a forward destruct bracket for missiles that was 93% cheaper and 15% lighter than the aluminum baseline (Fig. 2). “The aluminum part had a production lead time of 28 days; conversely, we molded 300 APEX parts in a single workday,” said Gardner in a 2014 Lockheed news article.

Back view of the thermoplastic nanocomposite bracket. Source | Alpine Advanced Materials LLC

The team began working to combine injection molded APEX with long-fiber composites to fabricate hybrid structures that offer maximum affordability and high performance. In one application — a next-generation, low-cost solid rocket motor case — 40 rocket nose cones were injection molded in two work shifts to demonstrate large-scale parts capability. “Our nose cones represent a 98% cost savings and a 99% improvement in lead time,” said Gardner. In 2011, APEX was approved to replace a more expensive continuous fiber-reinforced composite in the F-35 fighter jet’s wingtip fairings. The material was also used in more than 1,000 clips that stabilize the A2100 satellite main structure, and for clips, brackets and cable trays in other Lockheed missile defense products.

Gardner described the APEX material as a short fiber- and nanofiber-reinforced blend of “ultrapolymer.” It is also explained as a platform not limited to a single polymer, thus enabling customized, manufacturable formulations, including use with continuous woven and unidirectional fiber reinforcements. HX5 has passed fire, smoke and toxicity (FST) testing for aircraft interiors and high-temperature performance testing at 520°F/270°C.

“Alpine has plans to commercialize a variety of specialty materials, but HX5 is our flagship product for the foreseeable future,” says Bennett. The company does not sell the HX5 material but designs and manufactures custom parts. “We are prototyping HX5 parts that will be deployed across many industries,” he adds, noting replacement of aluminum in commercial aircraft and rotorcraft with a specific focus on interiors and piece parts for light weighting, which in turn reduces carbon emissions. HX5 is well-suited for redesigning aluminum or conventional composite assemblies to reduce part count.

Though the first HX5 parts will be injection molded, Alpine plans to exploit other advanced manufacturing processes, like overmolding. “Alpine also remains committed to improving the United States’ competitive position through participation in numerous defense development programs,” says Bennett.

Nano-CMCs for hypersonics

Further off the ground and at much higher speeds is another emerging application area for nanomaterials: Nano ceramic matrix composites (CMCs) for hypersonics. Hypersonic is an aerodynamic term for speeds much greater than the speed of sound, typically less than Mach 5. More broadly, hypersonics is a category of military weapons and vehicles designed to travel at hypersonic speeds. Such technology is in development throughout the world, including in the U.S.

Speeds beyond Mach 5 demand lightweight structural materials that can withstand 2480°C temperatures without melting or deforming, while resisting erosion and projectiles. This means they must be hard, mechanically tough and fracture-resistant. These vehicles also require specific electrical and thermal properties to conduct electricity and/or shield enclosed components. Even the latest metal technologies are struggling to meet all these demands.

Refractory ceramics — including metal carbides, metal nitrides and metal borides — have the lightweight durability to handle such extreme environments, but their synthesis and densification requires high pressures and temperatures above 1980°C, making them energy-intensive and expensive. Pure refractory ceramics are also too brittle.

The Graphene Applications Development Center (GADC) has recently been formed to develop graphene-enhanced thermoplastic composites. Read more here.

The US Naval Research Lab (NRL, Washington, D.C., U.S.) is using its expertise developing novel, high-temperature and fire-resistant phthalonitrile resins to advance a potentially inexpensive method for the direct fabrication of nanocrystalline-shaped refractory ceramics. The technology uses novel polymeric compounds to synthesize and densify these ceramics in-situ, in one step without the need for sintering ceramic powders at high pressures and temperatures. This development is led by Dr. Matthew Laskoski, NRL research chemist and acting head advanced materials section, and outlined in his 2018 article “Naval Research Lab designs composites for new platforms,” published in Vol. 5, No. 2 Naval Science and Technology Future Force magazine.

In this process, a new carbon-rich resin with polyphenol-type chemistry is blended with metallic powders via ball milling, a common technique used in nanomaterial processing. The resulting ceramic precursor can be compacted into discs, cones, spheres or other application-specific shapes. A reactive melt infiltration process — such processes are commonly used to produce (CMCs) — produces densified carbides in a 1370°C, pressureless, argon-filled furnace. The dense carbides are thus formed in a single-step reaction at lower temperature than and without the pressure of conventional sintering and hot-pressing techniques. Because the crystal size of the carbides is less than 40 nanometers, the resulting nanoceramics are not as brittle as courser-grained materials.

Another advantage is that the thermoset polymer acts as a meltable source of carbon that reacts with the metallic powder particles. It also facilitates reinforcing the ceramics with metals, carbon fibers and secondary ceramics. (An example of secondary ceramics can be seen in Fig. 1 (E) where the bi-phasic composite comprises a primary ceramic matrix and secondary ceramic reinforcement.) The resulting CMCs provide an avenue for further control of mechanical, thermal, electrical and ablative properties.

According to Laskoski, refractory carbides such as zirconium carbide and titanium carbide are unaffected by extremely high temperatures and are impervious to fire, plasma or atmospheric heating during hypervelocity travel. However, NRL’s polymer-derived nanocrystalline ceramics extend beyond carbides to include nitrogen-rich resins that can react with metals to form metal nitrides. NRL has developed silicon nitride, zirconium nitride and titanium diboride composites as well as methods to reinforce resulting CMCs with tough fibers. These refractory ceramics exhibit high strength, thermal stability and variable electrical and thermal conductivities that allow them to meet the demands of hypersonic vehicle components.

Engines for such vehicles absorb large quantities of heat and must dissipate it effectively, which even the most advanced metal alloys cannot do without loss of strength and structural integrity. Laskoski asserts that metal nitride and boride components are more apt to solve this challenge, while silicon nitride composites offer potential for high-strength, oxidation-resistant communications radomes. NRL is developing additive manufacturing technology that will incorporate nanostructures into these materials and further tune dielectric, thermal and electromagnetic shielding properties at a higher resolution than possible with currently available materials.

Nanocomposite toxicity and safe handling

Because nanomaterials are smaller than human body cells and blood cells, there are concerns about its toxicity, not just from worker exposure during materials manufacture and processing, but also when parts are machined, sanded and recycled. The Graphene Council recently published a webinar where the National Institute for Occupational Safety and Health (NIOSH, Washington, D.C., U.S.) discussed these issues and listed its resources, including three 2018 publications: “Protecting Workers during Nanomaterial Reactor Operations,” “Protecting Workers during the Handling of Nanomaterials” and “Protecting Workers during Intermediate and Downstream Processing of Nanomaterials.”

NIOSH states that it has completed extensive toxicological studies on only a few nanomaterials, including carbon nanotubes (CNTs). Because rats and mice exposed to CNTs and carbon nanofibers (CNFs) have shown persistent pulmonary inflammation, tumors and fibrosis (progressive lung scarring that makes breathing difficult), NIOSH emphasizes it is important to control worker exposure throughout nanomaterial production. Harvesting nanomaterials from reactors and cleaning reactors results in potentially high exposures. Workers may also be exposed during spraying and machining (for example, ball milling) as well as handling nanomaterials for weighing, packaging and mixing/compounding. NIOSH states that control of worker exposures appears feasible with standard techniques including source enclosure, local-exhaust ventilation, personal protection equipment (PPE) and best practices in cleaning and housekeeping for fine particulates.

The NIOSH recommended exposure limit (REL) for CNT/CNF is below 1 μg/m3 as an 8-hour time-weighted average (TWA). Analytical techniques such as scanning and transmission electron microscopy (SEM, TEM) may be used to ensure this threshold is maintained. NIOSH specifically advises that it is unsafe to use the OSHA permissible exposure limit (PEL) for graphite (5,000 μg/m3) or carbon black (3,500 μg/m3), and also that more research is needed to fully characterize the health risks of CNTs and CNFs, including long-term animal studies and epidemiologic studies in workers.

“CNTs have been quite well studied,” says Jo Anne Shatkin, president of Vireo Advisors LLC (Boston, Mass., U.S.), a workplace health and safety consultancy. “Ten years ago, we didn’t know, but now studies are showing the more drastic toxicity we feared has not really materialized.” She notes that the concern about high-aspect-ratio nanomaterials like CNTs is that they behave like carcinogenic silica and asbestos fibers. “But very few of the CNT materials studies meet that fiber paradigm at this point,” she explains. “However, there are still a lot of challenges. We have mostly tested pristine nanomaterials, not functionalized, as they are in use. Uncertainty remains because nanomaterials are so varied in composition, form and functionalization.” All these factors can affect toxicity, including the functionalization method and chemistry used. “You are creating properties that make the CNT react better with a polymer, but we don’t know how that affects the material’s interactions with blood or body cells,” she says. We’re not yet at a predictive stage. That is what we are exploring now. can we come up with a standardized model for evaluating exposure and toxicity that accounts for all of these variables?”

Shatkin describes work being done and a number of standard test methods under development at the American Society for Testing and Materials (ASTM, Conshohocken, Pa., U.S.) and the American National Standards Institute (ANSI, Washington, D.C., U.S.). “The ISO/ANSI TC 229 Nanotechnology Standards Development Group has dozens of standards for testing nanomaterials,” she says, “as well as occupational health and safety methods, such as how to conduct SEM and TEM for particle distribution measurements relative to PELs and RELs.” Shatkin notes that both ISO and ASTM have a standard in development that looks at the risk of nanomaterial release from composites via machining, sanding and other secondary operations. Here, at least, a preliminary green light has been given. Shatkin says work completed by the industry consortia NanoRelease shows that sanding and machining parts that contain nanomaterials do not pose new health and safety threats. “You do get release of nanomaterials, but they are bound to the polymer, not free nanoscale particulates,” she explains. “So, our current guidelines for particulates from machining composites are sufficient.” However, companies — especially those with limited workers and resources — may not see machining dust as a serious health threat. Thus, they may not always follow guidelines and best practices for PPE and respirators, not to mention enclosures and ventilation equipment. But because there is still uncertainty, such complacency isn’t an option when working with nanomaterials.

Nanocomposites are indeed enabling higher performance, greater multifunctional capabilities and potentially lower-cost and lighter-weight structures for numerous applications and markets. “There is a huge opportunity for benefit with nanomaterials, and we’ve learned a lot,” says Shatkin, “but there’s still a lot of uncertainty. Our best path forward is to be cautious, minimize exposure and make sure, as much as possible, that we make manufacture, handling and use as safe as possible.”

Related Content

MATECH’s FAST technology achieves ultra-high density C/C composites

Targeting demanding hypersonic missile applications and ballistic reentry, the patent-pending process increases C/C composite ablation and oxidation resistance by 20 times.

Read MoreThe future of quartz and oxide fibers at Saint-Gobain Advanced Ceramic Composites

New business builds on 100-year legacy in quartz, prepares for growth, while starting production of oxide fibers to meet increased demand for CMC by aerospace and industrial sectors.

Read MoreBio-based SiC ceramics from wood polymer composites

Austrian research institute Wood K plus makes 95% silicon carbide ceramics more sustainable (>85% bio/recycled content), enables 3D shapes via extrusion, injection molding and 3D printing.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreRead Next

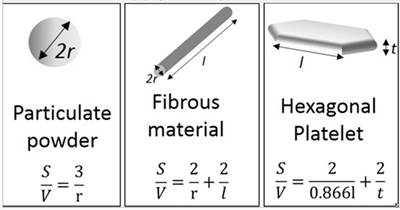

Nanomaterial types and definitions

Nanomaterials range in size, material, characteristics and usage in composites manufacturing. Provided here are types and definitions of those currently available.

Read MoreJoint venture to develop graphene-enhanced thermoplastic composites

XG Sciences, Sinochem Plastics, Yuyao PGS New Material Technology partner on advanced composites for automotive and industrial applications in China.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More