There is a strange dichotomy in publishing that has become more obvious since the advent of the Internet. I will use CW to explain this dichotomy. Each month, CW publishes a magazine for its subscribers (you). This magazine is printed and sent through the mail to some of you, or rendered in digital format and sent via email to others. We know a lot about our subscribers — job title, place of work, where that facility fits into the composites supply chain, markets served by facility, etc. We take it on faith that you read CW each month, but it’s very difficult for us to know what actually happens to that magazine after you receive it.

Conversely, on the CW website, we know a lot about the behavior of our audience. We know which stories are accessed the most (and the least). We know how much time, on average, an audience member spends reading a story. We know geographically where our site audience comes from. But we have precious little information about who the people are that use the CW site. We don’t know where they work, what their job is or where they fit into the composites industry’s supply chain — if, in fact, they fit into the supply chain at all.

What I can tell you, however, is that the digital community of composites professionals is a particularly active group. We know this because the level of activity on the CW website is distinctly and positively out of proportion to the size of the composites industry itself. We can only hypothesize about why this is so, but I suspect it’s rooted in dynamism built into the composites industry. That is, the variety of resins, fiber and processes engenders a high level of activity and change that compels composites professionals to seek information that helps them keep abreast of the latest developments. And, of course, CW’s core mission is to keep abreast of the latest developments in the composites industry.

As each year comes to an end, we often pause to take stock of the work we’ve done and how it might inform the work we will do in the future. How have the stories we published been received? What was well liked and what was not well liked? The behavior of users on the CW site help us answer these questions.

So, with 2020 nearly complete, I thought you might find it interesting to see some of what I see. Particularly illuminating are the top 10 most-viewed stories published by CW from Jan. 1 to Nov. 13, 2020 (the day I am writing this).

- “Designing the ultimate stand-up fishing kayak” (Hannah Mason)

- “3D printing CFRP molds for RTM exoskeletons and more” (Ginger Gardiner)

- “Carbon fiber pressure vessels for hydrogen” (Gardiner)

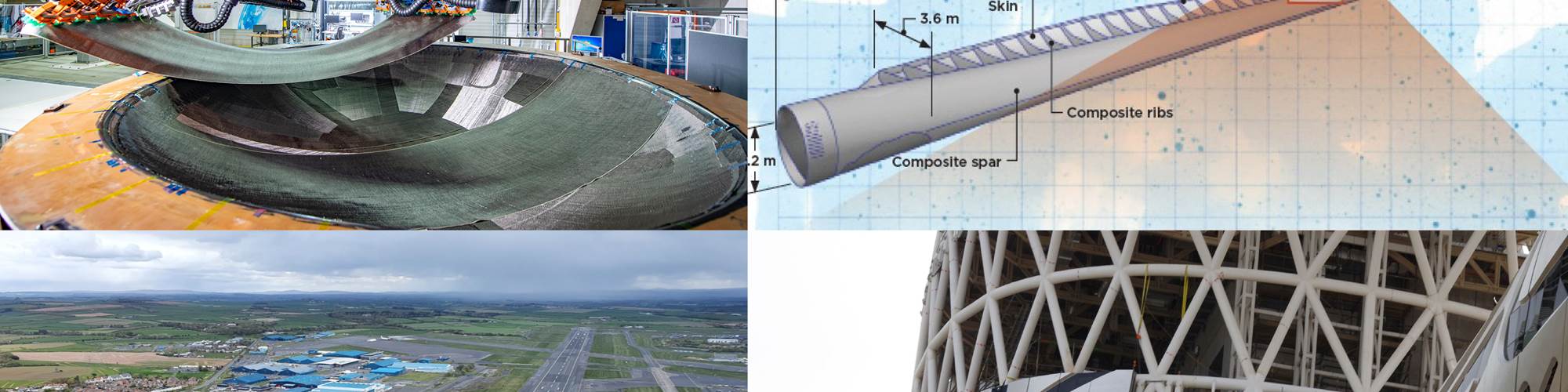

- “Update: Lower wing skin for Wing of Tomorrow” (Jeff Sloan)

- “Surface treatment for adhesive bonding: Thermoset vs. thermoplastic composites” (Mason)

- “High-rate, automated aerospace RTM line delivers next-gen spoilers” (Sloan)

- “Building the Museum of the Future” (Gardiner)

- “Automated aerocomposites production: Liquid molding or welded thermoplastic?” (Gardiner)

- “Composite aerostructures in the emerging urban air mobility market” (Sloan)

- “Reimagining wind blade design” (Sloan)

What does this list tell us? First, that the top-ranked story is about a fishing kayak might seem surprising, but on occasion some of our content, especially if it focuses on a consumer product, escapes the bubble of the composites industry and finds interest with a larger audience — in this case, people who like to fish from a kayak.

Second, despite the beating the aerospace industry is taking from the coronavirus pandemic, there is still clear interest in how composites are applied to aerostructures. Third, Ginger’s story (#7) on liquid molding versus welded thermoplastic tells us that these two processes are worth continuing to pay attention to. Fourth, the presence of stories about 3D printing, building and construction, pressure vessels and wind blades provide clues about end markets and processes that stimulate reader interest.

As 2021 begins, we are embarking on a fresh slate of stories for the CW audience. We have much planned, but we always have room for more. If you have some of your own ideas about stories or topics we should consider covering, please know that we always like to hear from our audience with ideas. Contact me at jeff@compositesworld.com and we can talk. Have a good 2021, and I hope to hear from you soon.

Related Content

Revisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

Read MoreAs 2023 begins, a look back at trending CW topics in 2022

With 2022 now behind us, CW’s editor-in-chief Jeff Sloan takes a look at the CW stories last year that received the most reader attention.

Read MoreRemembering Don Adams

When one thinks of composites test methods, one thinks of Don Adams. Don passed away at the end of 2022. We remember him here.

Read MoreUp, not out: The next chapter of CompositesWorld

I have been editor-in-chief of CompositesWorld for 17 years, which translates into a lot of editorials. This will be my last as I become publisher of CW. We welcome Scott Francis back to the brand to take my place.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)