Revisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

Source | OceanGate

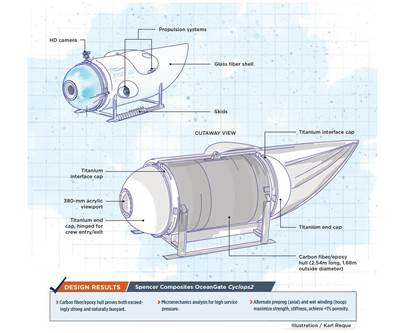

In June 2023, the world was shocked by the loss of the OceanGate Titan submersible. The incident sparked a burst of media coverage and in the weeks following the tragedy, which claimed the lives of five people including OceanGate CEO Stockton Rush, there was much speculation about the cause of the disaster. Many pointed to the use of carbon fiber composites, or at least the areas where carbon fiber was joined to titanium — a more traditional material used for submersible construction — as a potential cause of the vessel’s implosion.

On June 11, 2024, nearly a year after the Titan implosion, Wired released an in-depth article written by Mark Harris, outlining the events that led up to the disaster. Much of what is covered in the article, which is based on leaked documents and accounts from former OceanGate employees, serves to illustrate that the likely cause of Titan’s demise was, rather than any one material design choice, more closely linked to decisions that were made by Rush that disregarded the advice of the designers and engineers that he had surrounded himself with.

Naturally, at the time of the disaster, CompositesWorld (CW) was compelled to cover the story to lend additional insights from composites industry experts to the discussion. CW released a response from publisher and brand VP Jeff Sloan based on our coverage of OceanGate’s journey from initial prototypes through to the vessel’s preparation for expeditions. The editorial offered additional commentary regarding the complex design engineering, tooling development, fabrication processes and testing procedures that must be undertaken at every stage when making composite parts, particularly for such a demanding application.

In response to the mainstream press’s portrayal of Rush’s choice of a carbon fiber hull as the culprit, Sloan wrote: “Anyone who knows composite materials knows it’s not that simple, and it’s not fair to place blame for Titan’s failure at the feet of carbon fiber composites. In fact, this accident, the tragic loss of life notwithstanding, can and should provide an excellent lesson on the important and complex interdependence of materials, design, tooling and fabrication.”

Many of the points Sloan made in that initial commentary about materials selection, quality assurance and testing are further supported by Harris’ article. His discussion of the materials used for Titan treats carbon fiber more fairly than initial media portrayals, placing much more focus on necessary procedures, testing and precautions that should have been taken. One of the quotes from the article is from Chase Hogoboom, president and co-founder of Composite Energy Technologies, a company that has experience working with the U.S. Navy on submersible designs and the rigorous testing that goes into the use of carbon fiber for undersea applications. “Carbon fiber is a very sensible material if it’s been engineered correctly and manufactured in a controlled way,” says Hogoboom.

A year after the Titan disaster, there is still much we can learn from the incident. The reactionary judgment of the material choices has calmed and given way to a more rational study of the contributing factors that ultimately led to the vessel’s demise. Much of the evidence presented in Harris’ article indicates that Rush made many shortcuts in his race to complete a working submersible, often in the name of saving costs. Warnings were also repeatedly ignored and typical protocols were often circumvented. These findings highlight the importance of a thoughtful and exacting approach to design, materials selection, tooling, fabrication and testing in composites engineering. The tragedy serves as a lesson on the complex interplay of these factors in ensuring the safety and performance of advanced composite structures.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

Thermoplastic composite pipe on the rise in the deep sea

Demonstrators, pilot programs and qualification efforts are paying off as thermoplastic composite pipe (TCP) makers take orders for deep-sea oil and gas applications.

Read MoreComposite submersibles: Under pressure in deep, deep waters

Manned deepsea exploration calls for a highly engineered composites solution that saves weight and preserves life — at 6,500-psi service pressure.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More