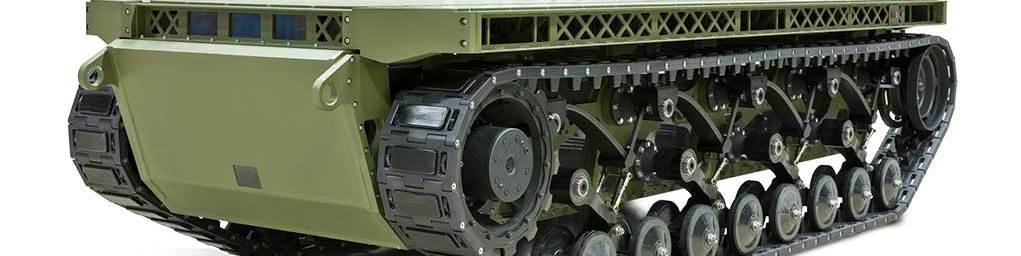

These composite half leaf springs were built by Thunder Composite Technologies for an autonomous, remote-controlled, battery-electric tank prototype developed by General Dynamics. The leaf springs were manufactured via Thunder Composites’ automated, continuous pultrusion process. Photo Credit, all images: Thunder Composite Technologies

Historically, land-based defense has been a difficult market for composites to break into, instead relying on legacy tank designs and materials. “To enter into that market, you have to really come up with a cost-competitive, automated system, or unique low-cost tooling that can be automated. They’re looking for weight savings, but they don’t have the big budgets to develop one-off systems [to replace the manual layup tooling currently available],” explains Andrew Glover, president of Thunder Composite Technologies Ltd. (Windsor, Canada) and owner/engineering manager at parent company Harbour Technologies (Windsor).

He continues, “The defense industry for land systems is completely different than the aerospace defense market, which is already in the composites realm. The defense industry is actually very similar in nature to the heavy truck market, and some vehicle platforms use some of the same steel tooling. For example, the tooling for a particular semi-truck roof structure might be used in defense for a similar part on a defense vehicle.”

Building on more than a decade of experience in automated, high-volume processes for automotive composites, Thunder Composite Technologies recently achieved its goal of entering into the defense market, developing a suspension system and composite half leaf spring for an autonomous, all-electric tank platform for global aerospace and defense company General Dynamics (Reston, Va., U.S.).

Entering automotive: Automated, continuous composite processes

Harbour Technologies is a family-owned company that has been building automated systems for a variety of manufacturing processes for more than 50 years, with customers in automotive, aerospace, defense, medical, nuclear parts manufacturing and more.

Composites fabrication company Thunder Composite Technologies spun off in 2009, offering engineering, prototyping, production and machining of composite components, as well as automation equipment and moldmaking via Harbour Technologies. For the automation equipment, Glover says the company can either develop a custom automated line for in-house production, or deliver systems for production at a customer’s facility.

Thunder Composite Technologies uses its automated pultrusion and RTM to design and manufacture leaf springs (top), tie rods (bottom) and other components for the automotive and defense markets.

Combined, Harbour Technologies and Thunder Composite Technologies operate out of four production facilities, with about 80,000 square feet of manufacturing space. “It’s a full turnkey package. We not only design and engineer the product, but we design, engineer and build the entire production system,” Glover says.

This emphasis on automation as well as the company’s proximity to Detroit, Mich., U.S. allowed it to quickly enter the automotive composites prototyping and production market with leaf springs, followed by steering axles, sway bars and more.

Glover explains that for its mainstay leaf spring components, Thunder Composite Technologies uses a patented process it calls hybrid pultrusion — essentially, an automated system for continuously pultruding composite parts with variable thickness. The process is said to be highly scalable, allowing for high volumes at relatively low cost, with cycle times as low as three to four minutes per part, depending on the application.

The system starts with a traditional pultrusion process, producing a part with a uniform thickness from continuous fibers and with a high fiber-to-resin ratio. This uniform pultruded “core” is moved into a secondary system, which winds wetted continuous rovings around the original part, resulting in a stronger part with tailorable material performance based on application requirements. This secondary step is similar to a filament winding system, Glover says, but with more control. “The whole system travels [along the part], and it’s a CNC-controlled system. We’re able to selectively add individual rovings onto the core structure, at any degree angle that we determine in the software.” A heated mold travels along the system and pulls the material through it to cure the finished part.

To optimize its composite leaf spring designs, Thunder Composite Technologies has developed a software program to reverse-engineer steel leaf springs. Mechanical properties of the steel part are input into the software program, which then produces a digital model of a comparable composite leaf spring, accounting for the new material properties and optimizing to prevent failure. “In our system, the unique thing is that it reduces the amount of engineering, so we come right out of the gate with a real close product that can be utilized in spring applications,” Glover says.

Using this software and its hybrid pultrusion process, Thunder Composite Technologies has produced composite leaf springs and half leaf springs for a variety of applications and customers in the automotive market.

Eventually, the opportunity arose to translate this knowledge and experience into the land-based defense market.

Opportunity for composites in next-gen defense vehicles

Thunder Composites says next-generation land-based defense systems are being designed to be smaller, more easily transportable, battery-electric and autonomous — and may provide more opportunities for composites to enter into the market.

Glover explains that next-generation defense vehicles are being developed that look and operate differently than legacy manned tanks, and that’s where the opportunity exists for composites. “They’re going all electric and autonomous, driven by remote control. The vehicles are getting smaller, stealthier and you don’t have to worry about the survivability of the vehicle as much when you eliminate the human factor. The payload is radically different,” he says.

Like the commercial automotive market, land-based defense vehicles can also benefit from the lightweighting that composites offer, though, Glover explains, the goal is less about fuel savings or range, but about more efficient tank transport by land or air. “You can make it lightweight enough to be able to carry more of them in a transport vehicle at once,” he notes.

Over the past few years, “we’ve become a go-to for the defense market for companies that want to take a steel component and reengineer it into a composite,” he says. One project Thunder Composites produced was a series of carbon fiber composite oil pans for defense vehicles, which Glover says included a unique resin system to enable high performance at high temperatures. The part was built via a low-vacuum resin transfer molding (RTM) system Thunder Composite Technologies developed that, Glover notes, uses relatively low-cost tooling and can achieve a Class A finish.

In late 2018, Thunder Composite Technologies was approached by General Dynamics to design and build a full suspension package for a 10-ton, remote-control, battery-electric tank prototype, including eight composite half leaf springs per vehicle built with glass fiber composites via the company’s hybrid pultrusion process. Completed in 2021, the package mixes steel, aluminum and composite components, all of which Thunder Composite Technologies designed, manufactured and machined in-house.

Thunder Composite Technologies designed the entire suspension package for General Dynamics’ land systems prototype, including composite leaf springs.

Thunder Composite Technologies and Harbour Technologies anticipate that additional opportunities for composites will arise as the land-based defense market continues to move toward portable, autonomous vehicles, and that automated processes will be key.

Meanwhile, the companies continue to develop automated processes for both their automotive and defense composites customers. For example, Glover says, “We’re developing a fully automated, continuous process to make coil springs, and we can do any size coils with quick changeover tooling. We see that market as being just massive,” he says. “We’ve been working on the system since probably 2012, and it’s finally at the engineering point where we’re ready to start producing on the system.”

Related Content

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

Read MorePlant tour: Renegade Materials Corp., Miamisburg, Ohio, U.S.

Renegade Materials is known for high-performance prepregs for aerospace applications. Following its acquisition by Teijin in 2019, the company has expanded capacity and R&D efforts on a range of aerospace-targeted materials.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreMilliken & Co. partners with MMI Textiles to offer Tegris thermoplastic

The commercial market partnership enables easier access to the Tegris thermoplastic composite fabric for defense customers in the quantities that they require.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)