Automotive CFRP: Repair or replace?

As more carbon composites are used on structural car components, how will crash damage be assessed and repairs be made?

The amount of carbon fiber-reinforced plastics (CFRP) used in the global automotive industry is still small, confined mostly to racecars, supercars and high-end luxury vehicles. However, recent strategic alliances between automakers and carbon fiber suppliers in response to increasingly tough fuel-economy and carbon-emissions standards make it a good bet that ultralightweight carbon composites will soon grace production passenger cars. And as processing speeds go up and raw material costs come down, carbon fiber-intensive volume-production cars will take to the roads in greater numbers. The inevitable accidents, however, will pose two challenging questions for OEMs, dealerships and body shops: How do they determine the extent of damage to CFRP structures? How do they decide whether to repair or replace those damaged structures?

On the small number of high-end autos on which carbon fiber composites already are used for body panels, those damaged hoods, deck lids/trunk lids, roofs, fenders and door panels are generally removed and replaced. Despite their cost, there is little economic incentive to attempt repairs on such parts, and this is unlikely to change in high-volume applications. However, as CFRP moves into more critical structural components on the chassis, it may not make sense to replace major sections of the vehicle structure. But, what then? Is there a way to repair/rebuild critical structures economically? In dire damage scenarios, will the entire vehicle be junked — an undesirable option for both owner and insurer? HPC recently sought out automakers whose cars already have significant structural CFRP content to get a glimpse of what repair strategies might emerge as CFRP goes mainstream.

Cues from motorsports

Ian Thomson, technical director of startup CFRP parts producer Moldex Composites Pvt. Ltd. (Surat, India), has more than 25 years’ experience with advanced composites for Formula 1 (F1) and endurance sports-car racing. A specialist in crash/energy-absorbing structures, he has patched a lot of damaged CFRP in his time. “Now, people seem a bit nervous about doing this, and the trend is to just bin a damaged part,” he says. “But in the old days, in the 1980s and early 1990s with Williams, Ferrari and Sauber, we’d sit around and work out how to make a repair and then just go do it. Of course, we didn’t tell the drivers,” he laughs.

Thomson describes seeing a lot of heavy curbing damage in nonstructurally critical areas, such as cases of wheels being pushed into the chassis after a “slight brush” with a wall. The team would start with a visual inspection and follow it with a coin tap test. “Sometimes we’d also use ultrasound to check for disbond,” he says. “Then we’d go around and literally patch the area. We’d bag it and use heat lamps or silicone heater blankets to cure the patch. In Formula 1, we already had all the tools to do that in-house, and it always impressed the boss when we could repair something.”

Thomson referred to a favorite book on repairing aircraft composite structures and kept an eye on what the aerospace industry was doing, then he adapted its techniques to race cars. Since carbon fiber composites on vehicles at that time were predominately unidirectional laminates, for nonstructurally critical areas, they would use patches approximately 1-mm/0.04-inch thick and extend the patch 25 mm/1 inch beyond the damaged area. But for structural areas that were more critical to suspension or driver safety, they would use huge overlap joints for extra security and then conduct a proof load test (using either a simple torsion test or a push/pull test for suspension joints) and compare measurements against those recorded throughout the season for each chassis that was built. “This helped remove the ‘myth’ among race engineers and drivers of a chassis going ‘soft’ — something that used to happen with a riveted aluminum chassis, but not with carbon composites,” he adds.

“We’d take the outer skin off, pare it back, and then take out the core and bond in a nice patch by creating a scarf joint, with a gradient whose ratio was 7 mm [0.28-inches] long for every 1 mm [0.039 inches] in thickness.” They would use the same kind of prepreg featured on the original part, but one with a more flexible curing window that would crosslink at a lower temperature (~80°C/~176°F). “We carried around a 3M prepreg with a 12-month ambient temp outlife that was originally developed for the military for patching bullet holes, and we’d use a 3M film adhesive to bond prepreg into the damaged part,” he recalls. “If the damage was really bad and we had to make another precured part to bond in, then we’d use a paste adhesive for attachment.” The default solution was another 3M product called 9323 adhesive, a versatile material that adhered well to most substrates. “We kept patching these cars and running them — sometimes as much as 10,000 miles [16,093 km] — until it was no longer worthwhile doing so, weight-wise.”

He acknowledges that repair strategies for road cars could differ based on the damage location. “There are a lot of body shops in Europe that can do repair work on composites, but if the damage involves the chassis, you really want it to go back to someone who knows what they’re looking at,” he recommends, recalling a recent case where there was a problem with a CFRP sports-car chassis racing at the Twelve Hours of Sebring event in the U.S. As it happened, there was a quality composites company nearby. Thomson and a structural engineering colleague in Europe talked the U.S. composites company through the repair. “It came down to the courage of the technical director, who appointed someone locally to deal with this problem, and his faith in me and my colleague. The composites company was asking the right questions, so we all felt comfortable. They made a very good repair on that chassis. Although it was in a critical area, it was a flat spot, so the repair was relatively easy to make.”

McLaren and the MonoCell

As McLaren Automotive Ltd. (Woking, U.K.) readied its new CFRP-intensive MP4-12C supercar for launch in 2011, the automaker committed to making the ownership experience as positive and affordable as possible with regard to maintenance, repair and parts availability (see “McLaren: Multilevel customer support,” under "Editor's Picks"). That’s a good thing, since this midengine two-seater features a one-piece, all-CFRP MonoCell, a monocoque passenger cell that would be beyond the capabilities of most body shops to even evaluate, let alone repair (see top photo).

Although the MonoCell is a predictable form onto which key components are mounted, and provides a stronger and simpler solution to chassis construction vs. metals, it’s also expensive. So McLaren’s first line of defense for postcrash cell repairs is to avoid them. The vehicle features aluminum crash structures, front and rear, that mimic the chassis structure of race cars. “We put a lot of effort into making sure the MonoCell is very well protected and that there is always a sacrificial element that will fail first,” says Claudio Santoni, function group manager, Body Structures, at McLaren Automotive. The company says these “bolt-on/bolt-off” structures not only absorb significant energy in a crash but they also are easy and relatively inexpensive to repair or replace. “This vehicle was designed with a very high level of modularity,” says Santoni.

He claims that multiple high-speed crashes into a concrete wall with the same MonoCell has proven their strategy: The cell remained undamaged even after three hits, with all damage limited to metal structures around the MonoCell (see third photo from top). “If we had done that with an aluminum cockpit, it would have been bent and cracked,” he says. “While you could have pulled such a car straight again, the welds are so fragile that it would have been very dangerous. What we’ve done here is a different concept, and we believe it has a clear advantage over aluminium and steel vehicle structures, which are more often repaired but run the risk of retaining undetected weaknesses.”

Santoni adds that incidents on the road during the car’s development program also indicated that the McLaren strategy is sound. After sacrificial elements were replaced, the vehicles were back on the road in no time. Based on more than 20 years’ experience in building carbon fiber supercar and sports car chassis, the McLaren team reports that the most common forms of chassis damage are caused by rocks striking the underfloor and well-intentioned but uninformed mechanics outside the McLaren network who position a car jack in the wrong place and damage the floor.

In such cases, after a careful visual and, if necessary, ultrasound inspection, McLaren leaves it to trained mechanics in its service network to execute simple repairs, which are done via infusion techniques at room temperature. More complicated fixes are dealt with by the engineering team that designed the MonoCell. In an extreme case, where damage is sufficient to affect the chassis, the vehicle would probably have had a severe crash, sustaining other damage. In such situations, Santoni says his team at the McLaren Technology Centre has lots of experience rebuilding individual sections of the MonoCell (and fixing other CFRP vehicle structures), so repairs are possible on sections that aren’t critical to crash performance — but if there was any doubt, the company would replace the MonoCell rather than risk a repair. Adds Santoni, “One of the commercial opportunities that industrialization of carbon chassis production gives us is exactly this: the ability to take this ‘no-risk’ decision-making to our quality control.”

Doctors without borders

As Automobili Lamborghini SpA (Sant’Agata Bolognese, Italy) made preparations for the 2011 launch of its newest two-seater, midengine rocket, the Aventador LP700-4, the company went to great lengths to improve on previous weight and structural rigidity benchmarks. The keys to reaching these goals was greater use of carbon fiber composites than on its predecessor, the Murciélago, and development assistance from The Boeing Co. and the University of Washington’s Automobili Lamborghini Advanced Composite Structures Laboratory (ACSL), both located in Seattle, Wash.

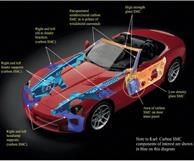

Like the MP4-12C, the Aventador features a one-piece, all-CFRP monocoque coupled, front and rear, to rigid aluminum subframes, but Lamborghini has used very different design and construction methods than its U.K. competitor. This unibody design encompasses a complete passenger cell, including the A- and B-pillars, the roof and the rear bulkhead that form a full roll cage for F1-type occupant protection (see photos four and five). Despite its performance, the entire chassis weighs only 147 kg/324 lb. The car also makes extensive use of CFRP on vertical body panels, the rear engine decklid and the rear air scoops.

Recognizing early on that such extensive use of carbon fiber composites would make field repairs a challenge, Lamborghini collaborated with Boeing and the ACSL to develop a strategy for assessing the level of damage sustained by Aventador CFRP elements and then provide specialized field support to customers. Casper Steenbergen, head of repair at Lamborghini’s Advanced Composite Research Center (ACRC), says, “We set up a complete strategy in order to determine whether to repair or replace pieces of a car if it becomes damaged. Of course, we made a lot of analyses with FEA and, from there, identified a few zones that are more critical than others to the safe operation of the car.”

The strategy for composites repair is based largely on the experience and knowledge gained from the collaborative research effort, begun in 2008, says Paolo Feraboli, Ph.D., assistant professor of aircraft materials and structures and ACSL director. Previously a contract engineer/scientist at Boeing and an engineering intern at Lamborghini, Feraboli says Boeing held workshops in Seattle a couple of years ago to train Lamborghini engineers and ACSL members to perform complex repairs on carbon fiber composites. In turn, the ACSL used this knowledge to support Lamborghini’s own ACRC in Sant’Agata, developing a repair strategy and establishing a global repair network for these vehicles. ACSL continues to support Lamborghini’s efforts to develop new ways to make repairs faster using leaner processes.

A customer with a damaged Aventador would first have it towed to the nearest Lamborghini dealership or repair shop, where the car would be examined. Next, a damage report (containing written and photographic documentation) would be prepared and submitted, along with a quick claim, via Lamborghini’s Web-based portal. Experts from several departments at Lamborghini’s ACRC would examine the information and try to determine the extent of the damage. If they suspect more serious damage, they would send a technician from an external company that specializes in nondestructive inspection (NDI) to take a closer look. The tech would bring field-portable ultrasound and thermography units and examine the vehicle for hidden damage in critical zones of the car.

A second report, including the tests results, would be sent back to Sant’Agata, where it would be examined alongside the original report. If the ACRC’s multidisciplinary team determines that damage has occurred to a critical chassis component, one of its specially trained technicians, who understands both carbon composites and the vehicle’s engineering, would be dispatched to fix the car. The automaker calls this elite group its “flying doctors” — there are only four of them, worldwide, at the moment — and says they are on call 24/7/365 to travel to any location where an Aventador’s composite structure has been damaged.

Equipped with everything necessary to make an advanced-composite repair in the field, the technician is prepared to make a relatively straightforward patch or a more elaborate co-plate (cut from a large piece of carbon composite) that would be used to strengthen the damaged zone. Because the vehicle combines a number of CFRP forms — including prepreg and RTM/braid on both Class A and non-Class A parts — the technician comes prepared with all the materials that might be needed to fix whatever is damaged (see “CFRP repair: Aventador,” under "Editor's Picks". Notably, Steenbergen says each flying doctor’s tool kit contains a hot bonder connected to two different heater blankets, each with its own controls, so two different materials with two different curing cycles can be repaired at the same time.

Depending on the extent of damage, the repair might take between 1 and 14 days. Steenbergen says that, thus far, only one accident was severe enough to require this level of support. Of course, a repair strategy like this is far less costly than replacing a major chassis component or scrapping a car.

Repairing bonded substructures

Because carbon fiber composite elements frequently consolidate multiple metal parts, and because adhesive bonding is an economical and load-capable method for attaching composite parts to the body in white, repairs could be problematic. But according to Mike Shinedling, Viper program manager, SRT Engineering, Chrysler Group LLC (Auburn Hills, Mich.), that need not be the case. Three-piece carbon-reinforced SMC fender supports on earlier versions of the Dodge Viper, for example, were bonded using a Pliogrip structural adhesive from Ashland Inc. (Covington, Ky.), then riveted together (mechanical fasteners fix the part while the adhesive cures) and bonded to the vehicle’s steel spaceframe. But when a Viper sustained damage to this structural part, mechanics at Chrysler dealerships would heat the part, remove it, clean the area and attach a new fender support assembly, using another grade of Pliogrip adhesive.

“With modern adhesives, it’s not a big deal to heat and separate bond joints so the parts are serviceable,” Shinedling says. “For us, bonding is a more efficient way to join structures by spreading loads out with the function of the part. And since it provides a barrier, it eliminates galvanic corrosion issues too.” He does acknowledge that for a mechanic in the field, it’s not always easy to judge whether a carbon fiber composite part is best repaired or replaced, but he adds, “Just like with metal parts, replacing the part will be the best solution every time.”

Challenge & opportunity

Of course, the big question, right now, is how BMW AG (Munich, Germany) intends to deal with repair of CFRP chassis components for its forthcoming i3 and i8 electric vehicles, due to launch in 2013. BMW declined to participate in this story, but with target production volumes of 100,000 under discussion for these platforms — orders of magnitude greater than the supercars mentioned here and, presumably, produced at an order-of-magnitude less cost — they will need to be repaired more cost-effectively in more places if BMW is to keep its customers happy. Once again, the composites industry is faced with the challenge and opportunity to step up and work in league with auto manufacturers to make composites-intensive (particularly carbon fiber composites-intensive) vehicles a reality by helping them develop easy, inexpensive methods to assess damage to structural components in the field and then repair them. One thing is sure: Proponents of automotive aluminum and steel will be watching.

Related Content

SMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreRead Next

How to patch a racecar

The current state of the art in automotive CFRP repair borrows heavily from experiences gained in the aerospace/aviation and racing fields.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)