How to patch a racecar

The current state of the art in automotive CFRP repair borrows heavily from experiences gained in the aerospace/aviation and racing fields.

The current state of the art in automotive CFRP repair borrows heavily from experiences gained in the aerospace/aviation and racing fields. This repair was made to a car owned by the Swiss Formula 1 race team, Sauber (circa. July 1997).

Step 1

Damage (white scars/scuffs) sustained by Formula 1 car when wheel was pushed into the CFRP chassis during brush with a wall during a race.

Step 2

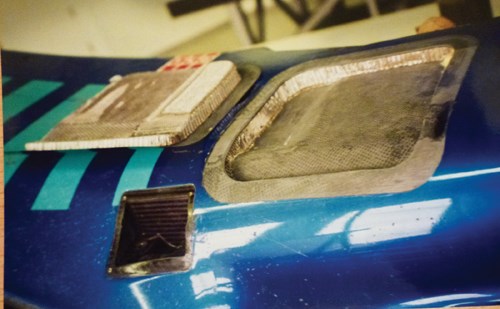

Outer skin and core removed from damaged area. Outer skin is chamfered with a 30-mm/1.2-inch wide beveled edge prior to being joined to patch.

Step 3

Repair patch is a precured outer skin with honeycomb that will be bonded in with a paste adhesive.

Step 4

Repair patch is a precured outer skin with honeycomb that will be bonded in with a paste adhesive.

Related Content

-

Heat-activated foaming core rapidly achieves net-shape 3D parts

CAMX 2024: L&L Products exhibits its InsituCore foaming core structural technology, which can be used to create foam core composites minus machining or presses, as well as the Phaster A K-700, a rapid-cure adhesive.

-

Henkel receives Airbus qualification for European aerospace manufacturing facility

The adhesive company’s Montornès, Spain, plant has been approved as a standard and raw materials supplier for various Airbus platforms, adding to its work in lightweighting, fuel efficiency and automation.

-

BiDebA project supports bio-based adhesives development for composites

Five European project partners are to engineer novel bio-based adhesives, derived from renewable resources, to facilitate composites debonding, circularity in transportation markets.

.jpg;width=70;height=70;mode=crop)