Building a better corrosion-control composite

Many FRP products used in corrosive environments — pipe, tanks, ductwork, stack liners and so forth — are constructed with filament winding or pultrusion processes and contain 60 to 70 percent glass fiber reinforcement by weight.

When it comes to corrosion, the diversity of the applications and corrosive elements requires a number of resin chemistries and the proper selection from many fiber reinforcements the one best suited for each environment. Many FRP products used in corrosive environments — pipe, tanks, ductwork, stack liners and so forth — are constructed with filament winding or pultrusion processes and contain 60 to 70 percent glass fiber reinforcement by weight.

In corrosion-control applications, part construction requires that the structural portion of the laminate, which supplies the majority of the strength and stiffness of the part, be protected from direct exposure to corrosive contents by a corrosion barrier. The barrier is resin-rich and typically consists of an inner surface veil backed by a mat of either chopped strand mat or chopped roving. For example, when RL Industries (Fairfield, Ohio) constructed three composite tanks for a chemical plant in Saudi Arabia, intended for storage of a 32 percent solution of hydrogen chloride or a 20 percent solution of sodium hydroxide, cylindrical sections of glass roving impregnated with AOC LLC’s (Collierville, Tenn.) Vipel resin were filament wound over a corrosion barrier formed with chopped strand glass mat and two layers of carbon fiber veil. Nozzles and attachment features for the ladders and rails were integrated into the wound sections. Top and bottom end enclosures, vacuum-infused with glass reinforcement and structural sandwich core, also were integrated during the winding process. Tank sections were assembled on site, using laminating techniques similar to those used to join chimney liner sections.

According to Reichhold (Durham, N.C.), which supplies its Dion anticorrosion resins to the market, “corrosion barriers are typically 100 to 125 mils thick and consist of a surfacing veil saturated to a 90 percent resin content, followed by the equivalent of a minimum of two plies of 1.5- to 2.0-oz/ft2 chopped strand mat impregnated with approximately 70 percent resin. The structural portion of the laminate can be sprayed up/hand layed with chopped strand mat, chopped roving or chopped strand mat alternated with woven roving, or it can be formed by filament winding. An additional ply of mat is sometimes used as a bonding layer between a filament-wound structural overwrap and the corrosion barrier.” A resin-rich topcoat also is commony used to guard against UV degradation and exterior corrosion.

A variety of fiber reinforcements — including E-glass, C-glass, E-CR glass and carbon — are used in corrosion-control laminates. E-CR glass, a boron-free fiber manufactured specifically to resist acid and alkali exposure, is widely used in the veils and structural layers of corrosion-control laminates, especially in chemical processing applications.

It’s critical to choose the correct fiber for each environment. When a corrosive chemical comes in contact with a glass fiber, via a microcrack or some other small failure of the corrosion barrier, use of the wrong glass fiber type could lead to chemical degradation of the fiber and eventually destroy the resin bond, resulting in laminate failure.

Traditional E-glass does not stand up well to most chemical incursions. “When immersed in 5 percent hydrochloric acid for two hours at 80°C/27°F, elements of the E-glass fiber are leached and replaced with hydrogen,” explains Kevin Spoo, a research associate at Owens Corning Composite Materials (Toledo, Ohio). This results in a porous layer that is more easily cracked under stress. E-CR glass contains no boron, however, so under similar conditions, it resists leaching. Owens Corning’s Advantex brand glass, developed in 1996, is a boron-free glass formulation that mixes E-CR glass and a boron-free, modified E-glass fiber reinforcement. The resulting reinforcement reportedly has increased mechanical properties compared to standard E-CR and E-glass.

Another option comes from PPG Fiber Glass (Pittsburgh, Pa.), which recently released INNOFIBER CR, a boron-free modified E-glass designed to reinforce polyester, epoxy and vinyl ester resin systems in pultrusion and filament winding applications, as well as multiaxial weaving. According to PPG, INNOFIBER CR can be used in the laminate portion and the corrosion barrier of a structure. The company’s HYBON 2002 CR roving, a continuous filament, single-end roving product, meets ASME D-578 Section 4.2.2 standards for E-glass and Section 4.2.4 standards for E-CR glass.

Related Content

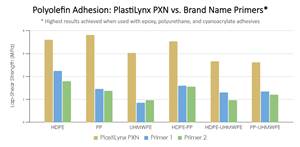

XlynX’s PlastiLynx PXN crosslinking primer enhances polymer adhesion

PFAS-free diazirine primer makes surfaces receptive to all manner of adhesives, including epoxies and polyurethanes, outperforming alternative options by 150-350%.

Read MoreScott Bader, Oxeco partner for high-performance bonding solution

Joint technology breaks barriers to bonding lightweight flexible solar panels to roofing structures made from aluminum, coated steel and composites.

Read MoreHenkel releases digital tool for end-to-end product transparency

Quick and comprehensive carbon footprint reporting for about 58,000 of Henkel’s adhesives, sealants and functional coatings has been certified by TÜV Rheinland.

Read MoreIPSA acquires bonding adhesives based on MMA technology

IPS Adhesives (IPSA) introduces a line of adhesives using acrylate and MMA technology from L&L Products for the bonding of dissimilar materials such as metals and composites.

Read MoreRead Next

Industrial corrosion control: Huge opportunities

Fiber-reinforced plastic is the ideal but still widely ignored option in environments that eat away at most metal alloys. Opportunities abound, but the key is still education.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More