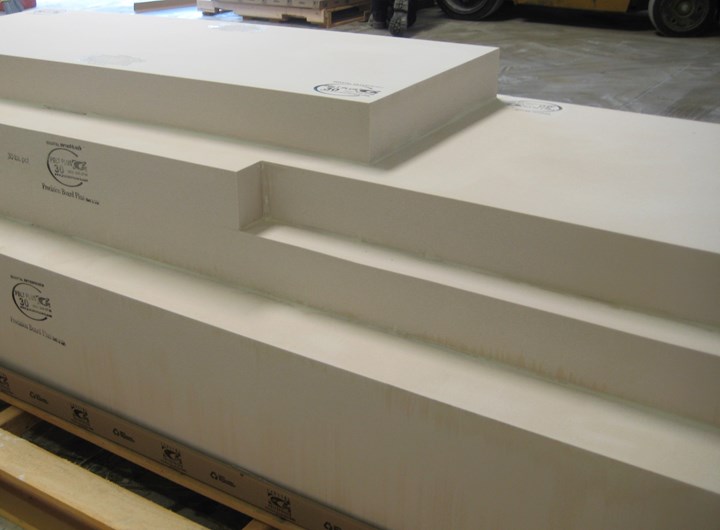

The tooling board company’s warehouse at its Orange, Calif., U.S. headquarters. Source | Coastal Enterprises

Many composites suppliers and fabricators have faced challenges over the past several months as a result of the coronavirus pandemic. High-density tooling board supplier Coastal Enterprises Co. (Orange, Calif., U.S.), a privately-owned company with about 25 employees, says that though it’s had its own share of challenges, the last few months have also opened doors to new and unexpected opportunities.

“The positive side of it is that through adversity, oftentimes, it's the fuel we need to find a better way,” says Chip Going, sales manager for Coastal Enterprises.

Going uses the word “nimble” to describe the company’s adaptability over the past few months. Coastal Enterprises’ relatively small size and private ownership, for example, have allowed it to quickly make high-level decisions, from adding new densities to its product lineup, to adding more custom bonding and cutting services, to slipping new, accelerated projects into the schedule. “Right now, things are changing so fast that for us to be able to react to people’s needs in real time is a huge advantage for us,” Going adds.

Many U.S.-based manufacturing companies have faced supply chain shortages over the past several months because they source their raw materials overseas, Going says. However, all of Coastal Enterprises’ raw materials come from U.S. sources, eliminating supply chain issues. “Top to bottom, we’re fully integrated,” Going says. “We do everything in-house, from mixing material, casting it, cutting it, packing it and shipping it. That allows us to be much more nimble in general, and in light of this crisis, we experienced zero supply chain issues.” The company also says it has continued to keep up with its lead times of 2-3 days for most projects.

This time can be seen as an opportunity for companies to rethink processes and material usage, and to explore new opportunities for innovation.

In addition, many manufacturing facilities are adjusting to operating with smaller, socially distanced staffs. “Companies are pushed up to their deadlines, with less people to do it,” Going says. “Sometimes with reduced budgets. They’re trying to complete the same project with less money and fewer people.” Companies with the ability to add custom services, like Coastal Enterprises’ custom bonding and cutting services, allow fabricators to lean on suppliers for services they normally may have done themselves.

All of these factors, Going says, have led to new opportunities for the company to serve new customers. “We’ve been able to step in and help companies whose supply chains have been disrupted to complete their jobs on time,” he says, adding, “It’s been a chance for companies to take a look at our products for the first time and, in some cases, find out that this is actually a great product option for them and their needs.”

However, Coastal Enterprises has had its share of adapting to new challenges, as well. Following federal and state guidelines, the company has worked to physically distance employees within its manufacturing facilities, develop staggered shifts for employees to reduce density within the facility, and encourage many workers to telework when possible. “It’s not easy, but it’s doable,” Going says.

Helping customers pivot

“You hear the word ‘pivot’ a lot,” adds Tai Freligh, marketing manager at Coastal Enterprises. “That’s another opportunity for us. I think people are discovering just how versatile Precision Board is.”

For example, the company has seen several of its customers pivot their usual manufacturing capabilities to help alleviate shortages in personal protective equipment (PPE), or to build products to help with social distancing such as sanitized wall panels or partitions.

One of Coastal Enterprises’ customers, which normally builds wall partition panels for offices and other buildings, pivoted to create partitions with antimicrobial film on them for use in hospitals, Going says. Coastal Enterprises worked with this customer to supply tooling board for use as core and as fixtures for producing the panels.

A custom-bonded Precision Board block. Source | Coastal Enterprises

Another company, Monster City Studios (Fresno, Calif., U.S.), which normally builds props for movie studios and themed environments for amusement parks, used the company’s tooling board to build molds for face shields. “We were able to quickly get them the material needed to start making molds for a prototype face shield design, getting the facility back into business again after it had been shut down,” Freligh says.

“Monster City Studios is a prime example of somebody doing something completely different from anything they’ve ever done before. And we’ve seen this all over the country, right?” Going says. “People are stepping up, filling a need.”

Looking ahead

Going and Freligh see this time as an opportunity for companies to rethink processes and material usage and to explore new opportunities for innovation. For example, Going sees tooling board coming into play for core and molding as manufacturers use composites to design and build physical barriers within aircraft interiors. “We’ll pivot to make sure that we use the resources that we have to manufacture stuff that’s helpful for people to figure out solutions moving forward,” he says.

Over the past few months, Going concludes, “people are being given the authority to take a step back and get creative. Because of this, there's a lot of positive that will come out from a manufacturing standpoint. Is it going to be messy over the next year to two years? Yes, but people have the opportunity to rethink things they maybe never would have had the chance to think about, which will be the catalyst for some serious innovations, especially in composites. Because of this radical pattern interruption, I think we’re going to see a huge fast-forward when we get back into things.”

Related Content

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreRead Next

Eastman Machine's customers shift gears to fight pandemic

Customers using cutting tables to fabricate composite parts and structures are turning to Eastman to retrofit for processing medical-grade fabrics.

Read MoreComposites suppliers, fabricators respond to coronavirus

Companies across the composites industry supply chain share how the COVID-19 pandemic is affecting their businesses, and how they are available to help.

Read MoreQuarantreat offers fast-build medical isolation studio for COVID-19 containment

Rapid dispatch design uses LitePan composite structural insulated panels and LiteTex thermoplastic composite laminates.

Read More

.jpg;width=70;height=70;mode=crop)