Composite Tether Goes To Sea

Conoco and KOP have manufactured a prototype of a carbon fiber composite tether that could extend TLP production to depths exceeding 10,000 ft/3,000 m. The design has undergone extensive static testing and fatigue loading and has been verified through hydrodynamic model testing. Sea testing is being planned.

Conoco and KOP have manufactured a prototype of a carbon fiber composite tether that could extend TLP production to depths exceeding 10,000 ft/3,000 m. The design has undergone extensive static testing and fatigue loading and has been verified through hydrodynamic model testing. Sea testing is being planned.

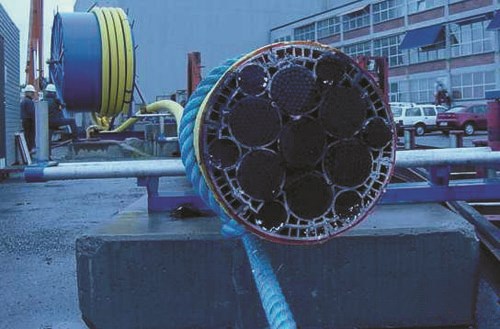

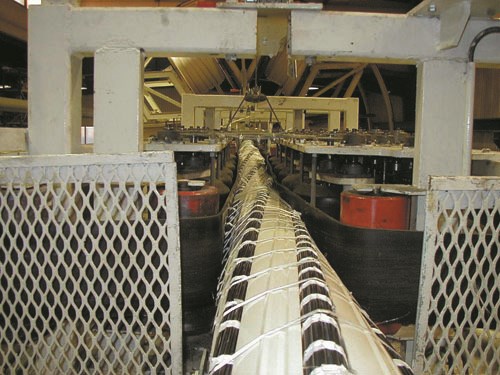

The first step in producing the prototype tether involved pultruding the carbon fiber epoxy rods. Small-diameter continuous rods (about 0.25 inch/6 mm) were pultruded from large tow PAN carbon fiber at the Exel Oyj Kivara Factory (Joensuu, Finland). The finished rods were transported on a 6 ft/1.8 m diameter spool to the umbilical manufacturing plant in Moss, Norway. Using wire-rope stranding methods, the rods were collected into 13 strands containing either 31 or 85 rods. The strands were covered with a polyethylene outer jacket for protection during handling. A light helical twist, about 2° to 3° on the outer rods, allows strands (and ultimately the completed tether) to be spooled without compromising much axial stiffness or creating torsional stress. In the finished tether, each strand is held in place with an extruded polyvinylchloride (PVC) profile that runs the length of the tether. The profiles separate the strands, but leave them free to move along the length of the tether, allowing them to adjust individually to stresses and better distribute the load. The strands and PVC profiles were assembled using an umbilical closing machine. In the final step, a polyethylene outer jacket was extruded and the finished tether was coiled on a 15 ft/4.6m diameter spool. The prototype tether is about 500 ft/150m long and 11 inches/280 mm in diameter. This design can accommodate as many as 100 rods in a strand, and as many as 40 strands in a tether, depending on the required strength and axial stiffness of the finished product. A continuous tether length of 10,000 ft/3,000m is attainable using current reeling facilities.

The tether’s end termination is a steel block similar to the anchors used for steel-wire tethers and suspension bridges. The block is machined with multiple cones, one for each strand of the tether. The individual metal cones more efficiently transfer the tether’s load to the steel anchor, and also serve to lock each strand into the steel block. Each cone is 5 to 10 times the strand diameter in length, at an angle of 3° to 5°. When a strand is potted, each cone is vacuum-injected with a metal-filled epoxy resin to eliminate air gaps and ensure consistent molding, then it is cured individually.

Conventional bottom connectors will be used to secure the composite tether’s termination to the seabed foundation. A top connector designed for steel tendons can be used in conjunction with a steel length adjustment joint where the composite tether connects to the TLP hull. A torsion resisting mechanism and tension monitoring unit are recommended for tendon tension adjustment and long-term monitoring.

Spoolable composite tendons are expected to be faster and easier to install than steel tethers. Because the finished tether can be spooled onto a relatively small installation vessel carousel, tethers can be transported and installed from conventional umbilical and flexible riser vessels, eliminating the need for expensive heavy-lift crane vessels. Alternatively, a combination of tugs, a modified cargo barge, and a DP vessel could be used instead of a reel ship. Both scenarios would significantly reduce installation cost and risk.

Related Content

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)