Composites and metal vie for fuselage and driveshafts in "Racer" next-gen, high-speed rotorcraft

New compound helicopter demonstrator set to fly in 2020 with hybrid fuselage and flexible metal driveshafts for twin pusher turboprops but will trial carbon composite shafts by 2021.

The Clean Sky 2 program is developing two types of future fast rotorcraft:

- Tiltrotor - generates lift and propulsion from rotors mounted on swiveling engine pods/nacelles on fixed wings or from tilting rotors driven through gearboxes from fixed engines.

- Compound rotorcraft – combines a rotor with a supplementary form of propulsion such as thrust engines or propellers.

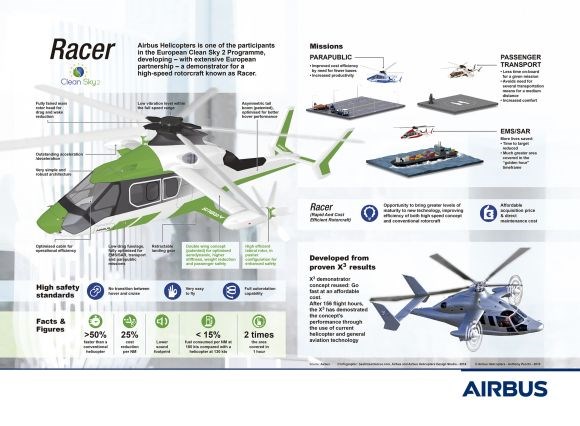

The Racer (an acronym for Rapid And Cost-Efficient Rotorcraft) demonstrator displayed by Airbus Helicopters (Merignane, France) at this year’s Paris Air Show (Jun 23-25, Le Bourget Airport) is a compound rotorcraft. Its box-wing design with pusher propellers received a US patent in 2016 and offers performance and safety improvements, according to Airbus Helicopters head of research and technology Tomasz Krysinski.

Racer was developed out of the previous X3 high-speed compound helicopter demonstrator, which set an unofficial speed record of 255 knots (472 km/h; 293 mph) in June 2013. Krysinski says the Racer’s box-wing generates more lift than the X3’s wing-stubs while the box-wing and pusher prop combination reduces power demand by 10% in forward flight.

The Racer future fast rotorcraft was developed from Airbus Helicopters’ previous X3 model. SOURCE: Airbus Helicopter

The Racer future fast rotorcraft was developed from Airbus Helicopters’ previous X3 model. SOURCE: Airbus HelicopterOne reported goal is to deliver 50% more speed than conventional rotorcraft but at only a 25% cost increase. The Racer is initially designed as a 5-tonne class light helicopter. Aimed at search and rescue, passenger transport and possibly military applications, it will cruise at 190 knots (350 km/h) with much lower fuel consumption than an equivalent conventional helicopter flying at 140 knots. One way it will do this is using an “eco mode” concept for the RTM322 engines which manufacturer Safran Helicopter Engines (Bordes, France) is testing. This “eco mode” will use an electrically powered “stop and start” of one engine while in cruise to reportedly generate fuel savings of 15% plus a longer range.

Other key features include main landing gear that retract into the Racer’s lower box-wing instead of the fuselage. Wheels can thus be located further apart, allowing a wider footprint for improved stability on the ground and use of simpler retraction and extension mechanisms.

Meanwhile, the Racer’s upper wing-box enables routing of bearingless, flexible driveshafts from the twin RTM322 engines to the propellers. Stiffer than a conventional wing, the box-wing deforms less, which Krysinski says enables simplification of the driveshaft design. He notes that Airbus Helicopters tested the principle of the flexible driveshaft on the X3 but the design has now been optimized in the Racer, both in terms of manufacturing processes and reduced mass. For the planned initial flight in 2020, the driveshafts will be metallic, but a second iteration will use carbon fiber composite driveshafts the following year.

Composites will also be used in the airframe, albeit alongside metal. Airbus Helicopters claims the Racer’s hybrid metallic-composite airframe has been specifically designed for low weight and low recurring costs. According to an article in Vertical magazine, composite specialist Aernnova (Miñano, Spain) will supply the aft fuselage.

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

Donauwörth as composites pioneer

Airbus Helicopter Germany produces composite primary structure for 30+ years, first all-composite doors for A350 XWB and latest “kinked” composite blades for new “quiet” rotorcraft.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More