Donauwörth as composites pioneer

Airbus Helicopter Germany produces composite primary structure for 30+ years, first all-composite doors for A350 XWB and latest “kinked” composite blades for new “quiet” rotorcraft.

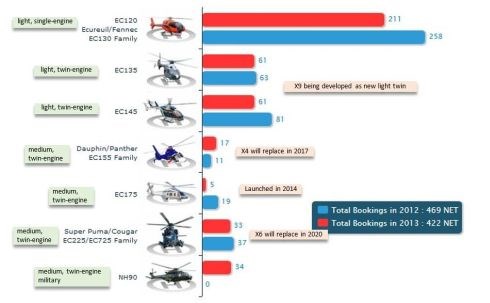

The X4 is one of three new Airbus Helicopters in development at Donauwörth.

SOURCE: Airbus Helicopters and AINonline.

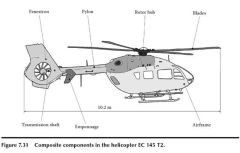

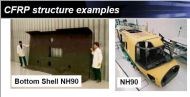

Airbus Helicopters (Marignane, France.), a division of Airbus Group, claims to be the world’s No. 1 helicopter manufacturer, with 46% market share in the civil and parapublic (e.g., search and rescue, medical transport, law enforcement) sectors. The company employs more than 23,000 people worldwide and its in-service fleet includes 12,000 helicopters (roughly 1/3 of the world’s civil and parapublic fleet) operated by more than 3,000 customers in approximately 150 countries. Its subsidiary, Airbus Helicopter Germany (Donauwörth, Germany) plays a key role in the company but also in the composites and rotorcraft industries. Donauwörth has become a center for production of large carbon fiber reinforced plastic (CFRP) structures, including the entire tail boom and fenestron (tail rotor shroud) for the EC 145 T2 and large unitized parts for the new soon to be revealed X4. Aviation Week reported that the site has also prototyped composite rotor blades produced with levels of automation reaching 80%. Indeed, Airbus has outlined automation and reproducibility as key needs and opportunities for composites in future rotorcraft. This blog gives an overview of composites in rotorcraft seen through the lens of this German hub of innovation and expertise

Donauwörth history and capabilities

Donauwörth was originally established in 1946 as the engineering company Waggon- und Maschinenbau GmbH Donauwörth (WMD) in the Swabia region of Bavaria. It began helicopter production as part of MBB (Messerschmitt-Bölkow-Blohm GmbH) in 1978, functioning as the manufacturing arm for designs developed at the Ottobrunn headquarters. MBB was taken over by Deutsche Aerospace AG (DASA) in 1989 and its helicopter division merged with that of Aerospatiale (Paris, France) in 1992 to form Eurocopter with headquarters in Marignane, France. Eurocopter was renamed Airbus Helicopter during the 2013 reorganization of EADS into Airbus Group.

Donauwörth has a long history in composites, including MBB’s significant development work in the 1980s and 90s and Aerospatiale’s use of composites in its glass fiber composite Starflex rotor system, first flown in the Ecureuil civilian helicopter in 1974 and in the Dauphin’s fenestron enclosed tail rotor, introduced in 1972 and which went all-composite in 1982. As part of MBB, DASA and then EADS Germany, Donauwörth collaborated with various Airbus and EADS divisions (in fact, EADS Innovation Works in Ottobrunn evolved from the MBB Central Lab) and notably developed an expertise in aircraft doors, including production for the Airbus A320 family, the A330 family and A380 aircraft.

Donauwörth now builds the EC 135 T2 and T3 variants, the EC145 C2 and T2 variants, and the EC635 and EC645 military versions of the 135 and 145, respectively. Airframer.net adds military helicopter components to its production, including main rotors for the Tiger and fuselage sections for the NH90. Donauwörth facilities include a composites center, a blade and mechanical center and the 30,000 m2 Systemhaus helicopter development center opened in 2013. Employment is listed as 5413.

SOURCE: Airbus Helicopters with descriptions and launch text by CW.

Composites in Airbus Helicopters

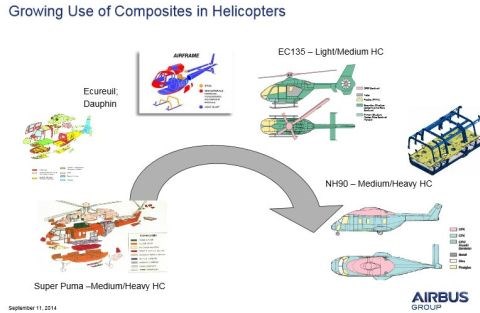

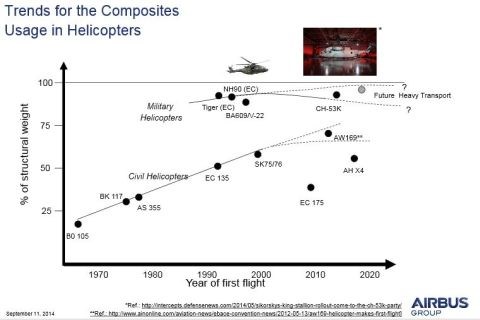

According to the book Composites Materials: Design and Applications, by Daniel Gay, by the end of the 1980s, composites were used not only in blades and hubs but comprised over 50% of the remaining rotorcraft structure. This structure became all-composite carbon fiber/epoxy during the 1990s.

SOURCE: Composite Materials: Design and Applications by Daniel Gay.

Composites use in Airbus Helicopters is shown in the slides below from a 2013 American Eurocopter presentation by Thomas Sippel titled “AEC Considerations in Rotorcraft Composites Development” and a 2014 presentation titled, “Composites in Aerospace, Future Challenges, Needs and Opportunities” by Dr. Christian Weimer, head of operations for composite technologies at Airbus Group Innovation Works, previously head of Eurocopter’s Institute for Composite Materials (Institut für Verbundwerkstoffe GmbH).

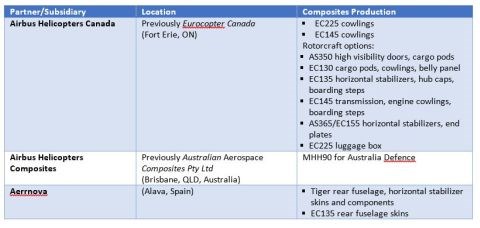

Airbus Helicopters partners in composites production include subsidiaries in Canada and Australia as well as Tier 1 supplier Aerrnova.

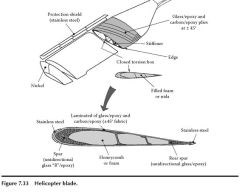

Composite rotor hubs

A helicopter rotor system is the rotating part which generates lift. It includes a mast, hub, and rotor blades. Notably, composites have performed in this flight critical structure for over 40 years, via the Starflex (glass fiber composite) bearingless main rotor hub which Aerospatiale pioneered and Eurocopter inherited, and the more recent Spheriflex (carbon fiber composite) system. Airbus Helicopters touts these as key safety technologies used across their product line, featuring a fail-safe design “through the application of composite materials.” This is because any damage evolves very slowly and is visible. They also reportedly ensure very fast response to pitch changes, excellent maneuverability and stability and are practically maintenance-free. The last benefit is because these systems replaced the old style bearings with laminated self-lubricating bearings and used the inherent flexibility of laminated composites for movement instead of mechanical hinges. According to Daniel Gay, the Starflex hub is made from a balanced glass fiber/epoxy layup of over 300 plies. Second Line of Defense shows a slideshow of the manufacturing steps for the Starflex (scroll to bottom of the page). The Ecureuil (EC130) also used glass fiber composites in the tail-rotor, formed by two blades attached to a composite beam. The latter, being both torsional and flexible, allowed this hinge system to be replaced as well.

Starflex bearingless rotor hub and production of the NH90 military helicopter.

Source: Airbus Helicopters.

New models and composites

According to Dr. Weimer, Airbus Helicopters definitely sees the use of composites in rotorcraft continuing to increase. Composites in the EC135 were credited with quiet operation (fenestron) and increased safety thanks to an energy-absorbing fuselage. It is hard to imagine surpassing the NH90’s reported 85% composite structure, yet Airbus indeed targets an increase should it proceed with a future heavy transport helicopter. Meanwhile, the composites content in civil rotorcraft is similar to that in commercial fixed-wing aircraft, averaging 50%. The EC175 (first deliveries were in Dec 2014) actually dropped in composites usage vs. the EC135. This is because aluminum was chosen for the airframe, perhaps because of cost or perhaps because this clean-sheet design was developed with its Chinese partner, Avicopter, which produces the main fuselage and is also creating its own variant of the rotorcraft, the Z-15/AC352 for the Chinese domestic market. The EC175 will compete in the new super-medium segment, initially against the AgustaWestland AW189, already in service, and eventually the Bell Helicopter 525 Relentless, still in development.

Source: Dr. Christian Weimer, Airbus Group.

Launched in 2014, the EC145 T2 is described as basically a new helicopter, even though it is a derivative of the long-running Bk115 that predates Eurocopter. Enhancements over its C2 predecessor include improved engines, new avionics and the largest shrouded Fenestron tail rotor (1.1m wide) that Airbus Helicopters has ever produced. Wolfgang Schoder, chief executive at Donauwörth, sites the new three-piece carbon fiber tail boom as one of the EC145’s key manufacturing advances. Designed and developed at Airbus Helicopters’ composite center of excellence in Donauwörth, the tail boom is a mostly monocoque structure, and not only saves ≈30kg vs. the previous all-metal design, but is stronger because it removes the usual stress point at the boom-vertical fin junction and is more able to cope with dynamic loads. Production was projected to ramp from 20 in 2014 to 50 in 2015 to possibly as high as 70 with a backlog of over 100 aircraft.

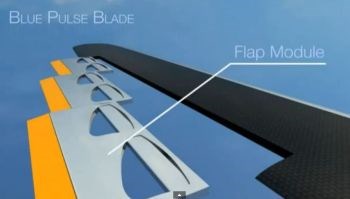

The new X4 helicopter will reportedly feature Blue Edge technology, part of Airbus Helicopters' Bluecopter program, which has also produced Blue Pulse technology.

SOURCE: Airbus Helicopters.

The X4 medium twin-engine helicopter is the next new development, designed to replace the long-running AS365 Dauphin/EC155 and the military version AS565 Panther. Scheduled to be unveiled unveiled on March 3 at the 2015 Heli-Expo show in Orlando, carbon fiber cockpit structures were shown to journalists in summer 2014, about the same time that fuselage components were delivered to the Systemhaus research facility. First flight for the X4 is scheduled for late 2015 with service entry in 2017. Another interesting aspect of the X4 is its use of Airbus Helicopters’ Blue Edge technology to reduce noise. The double arrow shape interrupts blade-vortex interactions (BVI) which occur when a blade impacts a vortex created at the blade tip. A five-blade Blue Edge main rotor has been flying since July 2007 on an EC155 testbed, demonstrating noise reductions of 3 to 4 dB.

The company has also developed a Blue Pulse technology which uses an active control system to reduce noise and vibration. The technologies, both developed within Airbus Helicopters’ Bluecopter program, were not developed to be used together. Piezoelectric actuators move the flap modules on the trailing edge of each rotor blade 15 to 40 times per second in order to completely neutralize the “slap noise” typically heard during descent. Blue Pulse technology has been flying since 2005, showing a noise reduction of up to 5 dB, and development of a production-ready system continues using an EC145.

Meanwhile, images have already made the rounds on the internet of what appears to be a heavily modified EC135 operating from Donauwörth. With a five-blade main rotor, wider-chord blades and the trademark kinked “Blue Edge” blades, speculation is that this is a testbed for the X9 development, currently scheduled to hit the market by 2018-2019.

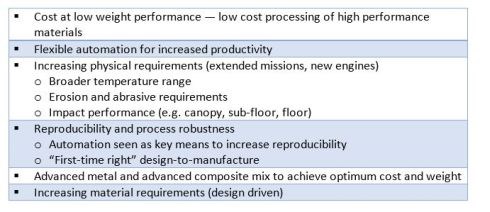

Needs and opportunities in helicopter composites

Dr. Christian Weimer’s 2014 presentation also outlined what Airbus sees as the future needs and opportunities for composites in rotorcraft. These include:

All-composite aircraft doors

Donauwörth’s long history in composites R&D extends beyond rotorcraft. Airbus Helicopters reports that 1,300 of its personnel work in development, production, and maintenance of fixed-wing aircraft components. Donauwörth has over 20 years of experience and produces more than 4,000 passenger and cargo doors per year for various Airbus aircraft. Upon receipt of the competitive contract to develop and produce the all-composite doors for the A350 XWB wide body aircraft, Schoder remarked that it demonstrated Donauwörth’s innovative strength and international competitiveness in carbon fiber technology. “The development and manufacture of aircraft components is another mainstay of Eurocopter’s activities in Germany, which complements our helicopter production.” He also said it confirmed Donauwörth’s decision to focus away from traditional metal structures to new manufacturing technologies based on composites. Benefits of the all-composite design reportedly include parts reduction, the application of advanced mechanical systems, additional safety features and equipment that is easier to maintain. A new building at Donauwörth was designed to enable automated production methods and quality control at high production rates.

Awarded in 2010, Donauwörth’s contract is for all A350 doors, each shipset including four pairs of passenger doors, two cargo doors and one baggage door. Korean Air Aerospace Division is a program partner, reportedly producing three of the doors, including the cargo doors.

According to an article by RTM press manufacturer WICKERT (Landau in Pfalz, Germany), it supplied a composite press system to Donauwörth, specifically developed for the production of the A350 XWB doors. The WKP 2500 S composite press for resin transfer molding (RTM) A350 door elements features integration of the injector, heating and cooling and press shuttle into the press control system. The press, which has one fixed upper arm and one fixed lower arm, features a 1200mm installation height, 2500 kN closing pressure, 2400 x 1800 mm mounting plates and 1000 mm piston stroke. Fully automatic mounting is carried out via shuttle which also handles return transport after processing. Cycle time at the Donauwörth production facility is reportedly 6 hours per aircraft door.

Wickert exhibited a complete A350 inner core door frame (left) at Composites Europe 2013 (Sep 17-18, Messe Stuttgart, Germany), manufactured using RTM with the WKP 2500 S Composite Press (right). SOURCE: Wickert

When asked if Donauwörth will get involved with further fixed-wing projects beyond the A350 doors, Schoder replied the door production comes out of the facility’s past and is an important business, but not its core. He said he had no intention to extend that cooperation or grow that partnership with Airbus Toulouse. And yet, it’s obvious the facility has developed the ability to supply large, high-quality, primary structure assemblies meeting full-rate production requirements, a feat which is still a struggle for some suppliers.

Related Content

Bio-based epoxy, recycled materials increase sustainability of all-terrain snowboards

Aiming for a smaller environmental footprint while maintaining high performance, Salomon’s Highpath snowboard line incorporates bio-based epoxy, glass and basalt fiber stringers and recycled materials.

Read MoreFrom the CW Archives: Fast-cure epoxies for automotive fabrication

Sara Black’s 2015 report on the development of snap-cure epoxies for automotive manufacturing still resonates today.

Read MoreJCB Aero aircraft interior flooring panels incorporate SHD composites

High-performance carbon fiber prepreg using SHD’s FRVC411 epoxy resin system resulted in a durable, compliant design for the MRO market.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More