Composites boon from hydraulic fracturing?

Hydraulic fracturing — commonly known as frac'ing — has become an efficient, if controversial, method for oil and gas extraction. Composite materials are helping pave the way in this very demanding application.

Hydraulic fracturing is fueling an energy boom in the U.S. According to the Society of Petroleum Engineers, 60 percent of all new oil and gas wells globally are being “frac'ed” and 2.5 million fracs have occurred since 2012, with more than 1 million in the U.S. The U.S. Energy Information Administration (EIA) forecasts an increase in domestic oil production from 6.89 million barrels/day in 2012 to 8.15 million bbl/d in 2014, with current drilling activity focused mostly on “tight” (low permeability) onshore formations including shale where horizontal drilling and fracking yield high initial production volumes, i.e. a lot of cash quickly.

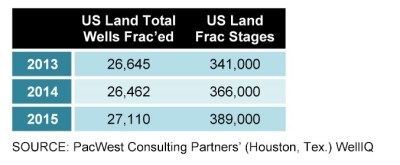

Composites have actually helped fuel this fracking revolution. According to the New York Times blog “A Turnaround in U.S. Oil Output” by Clifford Krauss, “Just a decade ago, complete wells were fracked at the same time with millions of gallons of water, sand and chemical gels.” Now plugs and balls are used to split each well into 20 to 40 isolated sections or “stages,”, increasing the pressure in each, which extends the system of fractures further from the wellbore and boosts the amount of oil and gas produced. Videos from Baker Hughes (Houston, Texas.) and Magnum Oil Tools (Corpus Christi, Texas.) illustrate this process. The table below shows the continued increase in stages, with each stage requiring a plug or ball.

Composite balls and plugs, typically made from glass fiber and epoxy or phenolic resin, are easier to mill out than metal versions and can withstand higher pressures and temperatures than traditional plastic and dissolvable salt balls. Frac balls typically measure from 1.0 to 5.75 inches/25.4 to 146 mm in diameter, while frac plugs commonly range from 4.5 to 5.5 inches/114 to 140 mm in diameter and 22 to 30 inches/559 to 762 mm in length.

The use of composite bridge plugs (same as frac plug but without flow path through the plug), frac plugs and frac balls is pervasive, including the “big four” oil service companies — Baker Hughes, Halliburton (Houston), Schlumberger (Houston) and Weatherford International (Zug, Switzerland). Other suppliers include Torquato Drilling Accessories (Old Forge, Pa.), Team Oil Tools (Tulsa, Okla.), and a wide array of smaller companies. Protek Systems (Grapevine, Texas) describes itself as a “boutique composite frac ball manufacturer,” and Boss Hog Frac Plugs (Houston) also supplies only composite products. Though Weatherford manufactures its products through its A&M Composites division (Big Spring, Texas) and possibly other locations, subcontract manufacturing of composite frac balls and plugs appears to be common. Such manufacturers include The Gund Co. (St. Louis, Mo.), Downhole Composites (Houston) and General Plastics & Composites (Houston, Tex.). There are also numerous manufacturers that use unreinforced phenolic, polyetheretherketone (PEEK), nylon and polyamide imide.

CW described 2002 state-of-the-art composite bridge plug technology as filament wound glass fiber and high-temperature epoxy resin for 4.5-inch/110-mm casing, pressure-rated to 8,000 psi/550 bar and able to withstand 250°F/120°C for at least one week with a drill-up time of less than 30 minutes. The same size plug today is temperature-rated to 300˚F/149˚C and capable of withstanding 12,000 psi/83 MPa, with Boss Hog claiming drill-outs in less than 6 minutes.

Even though Weatherford says its erosion-resistant frac balls are five times stronger “than anything on the market,” it is apparently seeking even higher performance with a November 2013 patent application titled, “Filament Wound Composite Ball.” Meanwhile, General Plastics & Composites’ 2012 patent uses “three dimensionally woven reinforcement . . . to alleviate the interlaminar shear limitations found in balls manufactured by typical composite laminates.”

However, the next wave of frac’ing technology may actually reduce the number of composite frac balls and/or plugs significantly. The goal, as always, is to cut time and cost. One approach is to use dissolvable frac balls, but made from stronger materials. Baker Hughes’ IN-Tallic frac balls are made from controlled electrolytic metallic (CEM) nanostructured material that is reportedly lighter than aluminum and stronger than some steels, but disintegrates when exposed to brine fluids. Terves Inc. (Euclid, Ohio) is developing TervAlloy magnesium and aluminum nanocomposite frac balls to withstand 15,000 to 20,000 psi/1034 to 1379 bar but disintegrate (turn to powder) when exposed to an electrolyte fluid or electrical or thermal stimuli. Both systems are designed to work with current frac sleeves and composite frac plugs but eliminate the milling out of frac balls and the potential for debris clean up, reducing well completion time and cost. However, Terves claims TervAlloy offers disintegration in hours versus the 1.5 days reportedly required for IN-Tallic frac balls. Terves is also claiming reduction in water use of up to 40 percent.

Composites may also be used in frac sleeves. These are lengths of tubing that include packers, pins or other means to wedge inside the well and isolate separate zones. They also have ports for releasing frac fluid and a seat for receiving frac balls. Multiple zones can be fractured with a single trip downhole by dropping a frac ball that isolates the zone and slildes open a port, releasing pressurized fluid to achieve fracturing. Moving toe (well bottom) to heel (curve from vertical to horizontal), the next ball is dropped to isolate and fracture the next zone. Weatherford’s SelectZone system has been used in North America’s Bakken shale oil reserve to deploy 25 to 30 separate frac zones within 24 hours compared to a typical 6- to 8-day installation for a typical composite plug and perforate (plug-and-perf) operation. Weatherford also claims this sliding sleeve system can cut water use by 30 percent via not having to push plugs downhole.

CCDI Composites (Santa Ana, Calif.) received a patent on Dec. 12, 2013 for a “Pin-less composite sleeve.” This sleeve refers to a composite tube at both ends of a composite bridge plug or frac plug that is used to encase the functional elements in the center section. The patent explains that composite sleeves are typically bonded and mechanically pinned to the frac or bridge plug mandrel. In wells at 350˚F/177˚C and 10,000 psi/690 bar, typical epoxy adhesives may fail, so multiple mechanical shear pins are used to affix the sleeve to the mandrel and withstand fracking pressure loads. The patent describes using an internal annular groove, helical groove and other measures to achieve the strength needed for elevated temperature and pressure service.

The continued opportunity for composites is to increase productivity at high temperature and pressure. In the U.S., demand for hydraulic fracturing crews often exceeds supply. Technology that can cut the process from eight to two days, for example, effectively quadruples the number of wells a single crew can complete, and reduces drilling rig rental cost. According to the 2012 Mines Magazine article, “Balls bump up efficiency of hydraulic fracturing,” a mere 10 percent increase in productivity in the Bakken Field would equal 50 million barrels, which is double the amount of oil recovered from Alaska’s Prudhoe Bay.

Related Content

CCG meets customer demand with StormStrong utility pole lineup

Additional diameters build on the portfolio of resilient FRP pole structures for distribution and light pole customers.

Read MoreCSub delivers one-piece composite truss bridge in Norway

EPC supplier has fabricated, transported and delivered a 42-meter composite bridge intended for pedestrians and bicyclists.

Read MoreSwedish parking garage to incorporate decommissioned wind blades

Architect Jonas Lloyd is working with Vattenfall to design the multistory building with a wind blade façade, targeting eco-friendly buildings and creative ways to remove blades from landfills.

Read MoreComposites end markets: Infrastructure and construction (2024)

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More