Mar-Bal’s Waste-Safe fire-resistant wastebasket. It is made from thermoset composites with fiberglass reinforcement and is available in a range of colors and sizes. Photo Credit: Mar-Bal Inc.

Although the use of composites in high-performance end markets like aerospace and automotive often receive most of the industry’s attention, the fact is that most of the composite materials consumed are applied to non-high-performance parts. The industrial end market falls into that category, and here material performance often emphasizes corrosion resistance, weather resistance, good fire, smoke and toxicity (FST) performance and durability.

Durability was one of SABIC’s (Riyadh, Saudi Arabia) goals for its manufacturing facility in Bergen op Zoom, Netherlands. The plant began operations in 1987 and processes chlorine gas, strong acids and alkalis at elevated temperatures, which are highly corrosive environments where steel pipes could fail in only a matter of months. To ensure maximum corrosion resistance and reliability, SABIC selected glass fiber-reinforced plastic (GFRP) for critical pipes and equipment from the start, and materials and manufacturing improvements implemented over the years have increased the design life of the composite components to 20 years, so that they need to be replaced less frequently.

GFRP pipes, vessels and assemblies manufactured by Versteden BV (Bergen op Zoom, Netherlands) using resins supplied by DSM Composite Resins (now part of AOC, Collierville, Tenn., U.S., and Schaffhausen, Switzerland), have been employed from the beginning. A total of 40-50 kilometers of composite piping, consisting of approximately 3,600 pipe segments of various diameters, is installed in the plant.

The 40-50 kilometers of GRP piping installed at SABIC’s Bergen op Zoom, Netherlands, plant contain highly corrosive chemicals, including chlorine gas, sodium hydroxide and hydrochloric acid. Photo Credit: CW

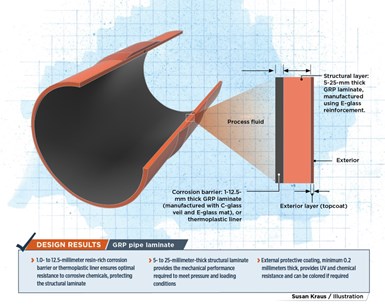

The composite components are produced using filament winding or hand layup, depending on the design, size and complexity of the part. A typical pipe structure consists of an interior corrosion barrier layer, 1.0-12.5 millimeters thick, for optimal chemical resistance; a 5-25-millimeter structural layer to provide mechanical strength; and an external coating about 0.5 millimeter thick to provide protection from the plant environment. The inner liner provides chemical resistance and acts as a diffusion barrier. This resin-rich layer is manufactured with C-glass veil and E-glass mat and has a standard nominal thickness between 1.0 and 12.5 millimeters and a maximum glass/resin ratio of 30% (based on weight). This corrosion barrier is sometimes replaced by a thermoplastic liner to prove greater resistance to specific materials. Liner materials can include polyvinyl chloride (PVC), polypropylene (PP), polyethylene (PE), polytetrafluoroethylene (PTFE), polyvinylidene difluoride (PVDF) and ethylene chlorotrifluoroethylene (ECTFE). Read more about this project here: “Corrosion-resistant piping over the long haul.”

Industrial tanks for storage of aggressive liquids is a common application of composites. In February 2021, Tecniplas (Cabreúva, Brazil), a manufacturer of tanks and special fiberglass-reinforced plastic (FRP) equipment, reported that it had completed installation of an FRP tank at a paper mill to extend the equipment’s useful life by 50%. According to Luís Gustavo Rossi, director of Tecniplas, the flow tower is used in the pulp bleaching process. “The customer has operated this type of equipment for a decade. However, in the last five years of use, some structural reforms were necessary, due to the high aggressiveness of the environment.” In addition to working with highly corrosive fluids, the tower operates at 70°C. With the support of the resin manufacturer INEOS Composites (Dublin, Ohio, U.S.), Tecniplas’ engineering department redid the structural calculations based on the ASME-RTP1 standard (for FRP vessels) and a 144 kilometer-per-hour wind load. With a diameter of 2,220 millimeters, the tower is 42 meters in height, with two 21-meter sections mounted in the field.

Composites can perform very well in applications that require good FST performance, but their use in trash receptacles is relatively rare. That said, according to the National Fire Protection Association (NFPA), every 24 seconds, a fire department responds to a fire in the U.S. In an effort to combat this problem, Mar-Bal Inc. (Chagrin Falls, Ohio, U.S.), a composites manufacturer and ISO 9001:2015-registered company, announced in July 2021 that it has developed the Waste-Safe fire-resistant wastebasket. Made at the company’s 110,700-square-foot facility in Painesville, Ohio, the fire-resistant wastebaskets are made from thermoset composites with fiberglass reinforcement and are available in a range of colors and sizes. The UL-classified and California State Fire Marshal (CSFM)-listed product line is able to contain a fire without burning, melting or collapsing, says Mar-Bal. When implemented, the wastebaskets are said to improve an organization’s overall fire safety plans and lead to an overall improved risk management plan. Designed for safety and efficiency, Waste-Safe wastebaskets will not burn or contribute to a fire, are low smoke and non-toxic and feature seamless construction.

Plate manufactured by Vantare with FCI anti-corrosion coating. Photo Credit: Vantare

In April 2021, FCI-Marbocote (São Paulo, Brazil), a company that specializes in the manufacture of mold release agents and anti-corrosion products, has launched its own coating for tanks that store drinking water. Named Ycon CS Acqua, the product was developed at the request of Vantare, a manufacturer of modular composite tanks. (CW has covered composite covers that protect water storage in Bogotá, Colombia.) Renato Ferrara, technical manager of FCI-Marbocote, explains that Ycon CS Acqua received the Innocuity Report, as required by Consolidation Ordinance No. 5, from the Brazilian Ministry of Health. “The tests were conducted by Newtech, a laboratory accredited by INMETRO [The National Institute of Metrology, Standardization and Industrial Quality], and the approval happened in the first round of rehearsals,” he observes. Based on isophthalic resin, FCI’s material is characterized by high levels of resistance (mechanical and chemical), adhesion and elasticity. “After being applied, Ycon CS Acqua promotes a film of high thickness and [is] totally inert [when] in contact with water,” Ferrara explains, noting that the product is ideal for the protection not only of composite substrates, but also of concrete, steel carbon and stainless steel.

Photo Credit: Solico

Also in April 2021, Solico (Oosterhout, Netherlands), a composites engineering specialist for the marine, architectural, defense and industrial sectors, launched its Amphora software for the design, calculation and optimization of composite storage tanks and silos. Composite materials are extensively used in the industrial and agricultural sectors to produce large, lightweight, corrosion-resistant, easy-to-install and low-maintenance silos and tanks for stored powders and liquids. In Europe, the design and workmanship of such above-ground storage tanks and vessels is typically defined by the EN 13121-3:2016 standard. Amphora is a user-friendly and customizable tool that uses specialized models to calculate and optimize construction variables for silos, vertical and horizontal tanks, so GFRP tank and vessel engineers may go through step-by-step geometry, load calculations and laminate thicknesses when building up a silo, eliminating uncertainties. The in-house-developed Amphora software also enables users to develop EN 13121-compliant designs based on their own materials and production parameters, per the creation of a database in the materials list feature.

In September 2021, SABIC (Riyadh, Saudi Arabia) reported that its subsidiary in Jubail, Saudi Arabia, called Petrokemya, which operates a petrochemical complex that produces a variety of feedstock chemicals such as ethylene, styrene, chlorine, crude industrial ethanol and more, required a combustion unit with several large components and pipes that must withstand hydrochloric acid without corroding.

The quench tank and scrubber during trial and fit testing prior to installation. Photo Credit: AOC

Design and manufacture of the combustion unit quench tank, scrubber, exhaust tank and associated vessels and piping was tasked to a team that included corrosion-resistant equipment fabricator Ollearis (Martorelles, Spain), contractor China Tianchen Engineering Corp. (TCC, Tianjin, China) and engineering firm John Zink Hamworthy Combustion (Tulsa, Okla., U.S.). These components were required to withstand contact with hydrochloric acid, meet several design challenges and be a cost-effective solution. Glass fiber-reinforced composites were chosen as a material able to withstand the highly corrosive chemicals, while offering a more cost-effective solution than specialized metal alloys. All major components were constructed from fiber-reinforced plastic (FRP), with a few minor exceptions including lifting and hold-down lugs (stainless steel), spray nozzles (thermoplastic or metallic) and scrubber packing.

To provide the most economic solution while satisfying performance requirements, Ollearis turned to three AOC Atlac resins. “We selected the resin types using the AOC Chemical Resistance Guide as well as the expertise from AOC’s technical service team, considering the fluids handled and the design temperatures detailed by the client. It was necessary to make sure the resins proposed would perform well under [the required] conditions,” explains Adriano Ureña, technical manager at Ollearis.

Ollearis selected Atlac 590 epoxy Novolac resin for the quench tank, Atlac 430 bisphenol A epoxy vinyl ester resin for the exhaust stack and Atlac 383 unsaturated bisphenol A polyester for piping installed around the scrubber and quench tank. The quench tank, scrubber and cylindrical parts of the stack were manufactured via a hybrid manufacturing process, combining wet filament winding with an exterior layer of bidirectional woven fabrics applied simultaneously. This combination produced parts with better mechanical properties in both the hoop direction (from the filament winding) and axial direction (from the fabrics, which align with the part axis). The addition of woven fabric also reduced the weight percentage of glass fiber per part, from 70% for a fully filament-wound part to 55%. This increases the amount of corrosion-resistant resin per part. Other components were produced via hand layup.

Related Content

Composites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

Read MoreYour must-have composites industry guide for 2025

Welcome to CW’s annual SourceBook, your guide to suppliers of machinery, materials, software and other services for the composites industry.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreComposites end markets: Industrial (2024)

The use of composites in industrial applications is increasing, driven by the need for higher performance and longer life, whether its parts for industrial machinery, EOAT components, corrosion-resistant equipment and more.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)