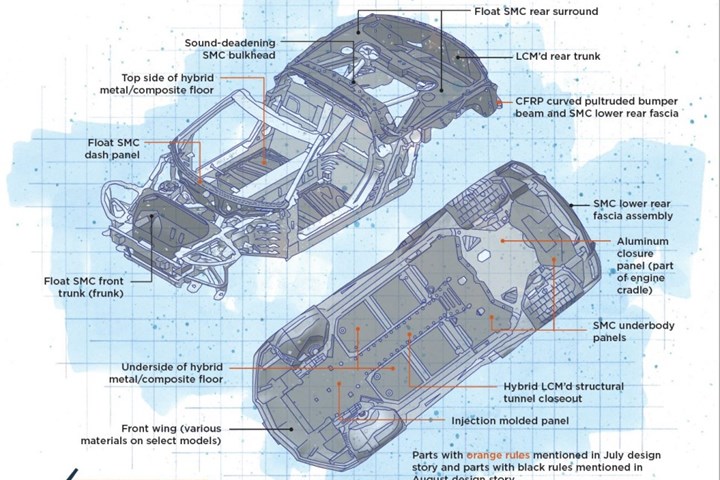

Design results of the mid-engine Corvette. Source | Sue Kraus

For Part 2, read “Composites-intensive masterwork: 2020 Corvette, Part 2”.

The much-anticipated eighth-generation Chevrolet Corvette (C8) from General Motors Co. (GM, Detroit, Mich., U.S.), which has been generating accolades since its official reveal on July 18, 2019, began commercial production earlier this year. The new Corvette Stingray convertibles and coupés are notable not only for their beauty and the fact that GM has produced a high-performance, street-legal, mid-engine rocket ship starting at less than $60,000 USD — one-third the price of comparable-performance mid-engine cars — but they also sport an impressive array of new and genuinely innovative composites content, which we’ll describe here and in Part 2 next month.

New engine configuration changes everything

GM engineering went into preliminary design knowing they’d be working on a mid-engine vehicle — the first production Corvette in eight generations to sport that configuration. “We evolved the front-engine architecture as far as we could for performance, so shifting to a mid-engine design was the next logical step to improve an already great car and be the segment leader,” explains GM’s Tadge Juechter, executive chief engineer-Global Corvette. Equipped with the Z51 performance package, the 2020 Corvette Stingray can accelerate 0-60 mph (0-97 kmh) in 2.9 seconds and reach top speeds of 194 mph (312 kmh). Pushing the engine toward the vehicle’s rear affected many things, including the car’s center of gravity, the relative position of occupants, transmission location and design of underbody panels and trunk storage. The mid-engine design also introduced higher operating temperatures and noise to new areas of the car.

The eighth-generation Chevrolet Corvette — all eight generations (C1-C8) shown above, left to right respectively — from General Motors Co. started production earlier this year. This mid-engine sports car is not only impressively fast, and the most composites-intensive Corvette yet, but it features an array of genuinely innovative composites applications. Source | General Motors Co.

“Because of the mid-engine, we had to do things differently,” explains Ed Moss, Corvette body structure engineering group manager. “From the start, we had so many discussions about how to lay out the body structure. At one point, everything was on the table as we discussed the best way to design and build each system. For example, we debated metallic versus composite for wheelhouses. If we’d kept the C7’s composite wheelhouses, we’d have to bond to the hinge pillar [A pillar], which is immediately adjacent to the front wheel in a mid-engine vehicle, leaving very little package space. We went with metal there. We even briefly discussed metal versus composite body panels. However, it would’ve been economically infeasible to create the C8’s styling lines in metallics.”

“A real challenge we faced was how to handle air induction,” recalls Chris Basela, Corvette body structure lead engineer, explaining the need for a different method to funnel cooling air into and across the naturally aspirated, 495-horsepower, 6.2-liter V8 engine, which generates 470 foot-pounds (637 Newton-meters) of torque. “We tried all kinds of designs that forced air to take really torturous paths, creating eddies and flows we didn’t want. It took lots of iterative work with the powertrain team to develop the best path for airflow because the car needs to breathe freely with no restriction. We also needed access to the air box and had to work around rear trunk space. Another issue was heat and engine noise in the passenger compartment, because occupants no longer sit behind the engine but are positioned directly in front of it. And we were especially conscious of cabin air quality as laws had changed in Europe and elsewhere since the C7, so we worked really hard to reduce VOCs [volatile organic compounds].”

“Even working out how to assemble the car was a challenge,” adds Moss. “With a front-engine design, you have a long hood and large engine compartment, providing operators plenty of room to build the car from inside the compartment, even with the front bumper beam already welded on. On the mid-engine Corvette, with its very short front clip, we keep the front of the car open as the vehicle is built out, then bolt on the front bumper.”

“It was quite a balancing act to get the proper shapes, while ensuring our suppliers could produce the parts and our team in Bowling Green [GM’s Kentucky-based Corvette assembly plant] could assemble them,” continues Basela. “In the end, there was only one carryover composite from the C7’s body to the C8.” This was tough Class A, 1.2 specific gravity (SG) sheet molding compound (SMC) developed for the 2016 Corvette and used in a variety of exterior closures on the new vehicle.

Vehicle architecture

For four generations (C5-C8), Corvettes have featured a three-layer, multi-material body structure: the frame, usually a mix of aluminum or steel — this time with a carbon fiber-reinforced composite (CFRP) part; the body structure, which is largely bonded composite to capitalize on design and manufacturing flexibility; plus bolt-on closeouts (body panels), which have been composite since Covette’s June 1953 debut. This layered hybrid structure not only provides affordable lightweighting in high production volumes — particularly for cars of this performance class — but also permits multiple vehicle variants to be produced at low tooling investment. In fact, for the current C8, GM managed to produce all Class A composite body panels (bonded inners and outers) on both the base model coupé and convertible using just 20 tools.

GM and its suppliers have already won many awards for innovative composites use on the 2020 Corvette Stingray. Among those standing above are key GM engineering team members at last November’s 49th annual Automotive Innovation Awards Gala, where GM won SPE Automotive Div.’s Vehicle Engineering Team Award. A number of composite parts on the vehicle also were finalists or category winners at the event. Source | SPE Automotive Div.

In addition, Corvettes have always been engineered with an open-roof architecture, regardless of whether they are actually convertibles or coupés with fixed or removable roof panels. Because open-roof vehicles are generally less stiff than those with fixed roofs, an important focus for each Corvette’s engineering is always to create the stiffest foundation possible to improve suspension and steering. Historically, tunnels (housing transmissions and driveshafts on front-engine vehicles) have dominated Corvette body structures and have been key enablers for achieving high torsional rigidity. In the case of the new Corvette, GM achieved even higher rigidity. With the roof removed, the C8 body is 53.78% stiffer than a benchmark high-performance mid-engine competitor, 29.27% stiffer than a second high-performance mid-engine competitor, and 13.79% stiffer than the C7. Two composite parts made important contributions to vehicle stiffness—one directly attached to the frame structure (rear bumper beam) and another attached to the underbody (lower tunnel closeout).

Frame structure

The C8’s frame is largely aluminum alloy with one CFRP part developed to meet GM’s stringent dollar-per-kilogram targets. In contrast, the C7 frame was all-aluminum and the C6 was mostly steel.

The only composite part directly mounted to the frame that travels with the body-in-white (BIW) through the electrophoretic rust-coat process (which GM calls ELPO), is a unique CFRP rear bumper beam. This part helps stiffen the frame and contributes to rear-impact performance. Its curved shape — possible thanks to a novel process called radius pultrusion developed by Thomas GmbH + Co. Technik + Innovation KG (TTI, Bremervörde, Germany) — enables it to match rear styling cues and fit in limited package space while maintaining dimensional integrity close to engine-bay heat. As the auto industry’s first curved pultruded part (see our full feature on this part in the CW May 2020 issue), the hollow, two-chambered beam was produced by Shape Corp. (Grand Haven, Mich., U.S.) on equipment developed and built by TTI. The beam weighs just 1.3 kilograms and features a bonded/bolted tow-hook eye capable of 25 kilonewtons of pull-out force.

An auto industry first, the 2020 Corvette sports a curved rear bumper beam in pultruded carbon fiber composite produced with 87 individual carbon tows and eight carbon fiber non-crimp fabrics (NCFs) impregnated with polyurethane-acrylate resin. The hollow, two-chambered beam is 66% lighter than the outgoing aluminum beam and met GM’s demanding dollar-per-kilogram targets. Source | Shape Corp.

Body Structure: part A

Virtually all of the C8’s body structure components are composite and are bonded and/or bolted to the frame after the latter undergoes ELPO. Notable composite parts at this level include structural underbody closures and the floor — which we’ll cover in this issue — and front and rear trunks, induction ducts and the rear surround and bulkhead — which we’ll cover, along with body panels and trim, next month.

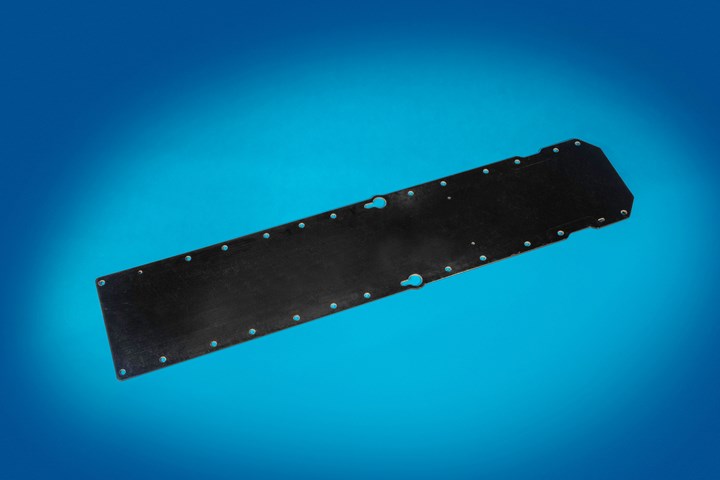

This hybrid-composite, lower-tunnel closeout is produced using a variant of liquid compression molding. It eliminated secondary attachments, lowered mass by 3 kilograms and reduced labor, tooling and capital costs vs. aluminum. Source | SPE Automotive Div.

The removable lower-tunnel structural closeout on the C8, which acts as an access door, contributes more than 10% of the vehicle’s torsional rigidity and acts as a primary load path during a crash. This hybrid-composite panel consists of three layers of glass fiber preform. These consist of continuous/woven and chopped/random fibers at 38% fiber volume fraction (FVF), with veils added to top and bottom face layers on each stack for improved surface finish. Glass preforms are interleaved with two layers of preforms made using Toray (Tokyo, Japan) T700 12K standard-modulus carbon fiber in the form of NCF biaxial fabric at 21% FVF and a vinyl ester (VE) matrix. The closeout is produced by Molded Fiber Glass Co. (MFG, Ashtabula, Ohio, U.S.) using its proprietary PRiME (Prepositioned Reinforcement ensuring Manufacturing Excellence) process, a type of liquid compression molding (LCM).

Aside from a single aluminum closeout near the rear wheels that is part of the engine cradle, the remaining underbody panels consist of either compression molded SMC or injection molded thermoplastics. Among other benefits, these panels reduce underbody turbulence and drag, improve fuel efficiency and keep moisture, dust and stones out of the vehicle’s engine and driveline. Further, they provide the dimensional foundation for multiple exterior and interior interfaces.

The low-density but structural SMC panels feature new formulations (in this case, 40% FVF chopped fiberglass/unsaturated polyester (UP) resin) developed by MFG. The material is called “float” SMC because each panel’s density is less than 1.0 (average SG=0.97) and thus can float in water. MFG produced all structural SMC and LCM’d parts on the car.

An important contributor to vehicle lightweighting on the C8 is the extensive use of “float” SMC. With specific gravity values less than 1.0, this low-density but structural SMC developed by MFG is used in a variety of non-Class A parts, including underbody panels, the dash panel, air-induction ductwork and the front trunk. Source | Molded Fiber Glass Co.

The vehicle also sports a hybrid floor optimized for torsional bending and side-pole impact protection (engaging the rocker panels and tunnel, to which it is joined). Floor panels feature cabin-facing stamped aluminum bonded to sheets of road-facing 1.5-SG composite (60 wt-% continuous and woven glass fiber/VE) produced via the PRiME process. Before heat-bonding both layers with Pliogrip 9100 polyurethane structural adhesive from Ashland Global Holdings Inc. (Wilmington, Del., U.S.), MFG cleans and preps the materials.

All composite parts directly bonded to the C8 frame are first subjected to laser ablation, a process developed by GM, MFG and Adapt Laser Systems LLC (Kansas City, Mo., U.S.) for the 2016 Corvette, and adapted from a composites industry method for mold cleaning. Laser ablation replaces hand sanding and reduces labor, time and cost, eliminates dust and improves repeatability. Laser path, angle of attack and energy level are customizable for each part’s material and geometry. To maximize manufacturing flexibility, the entire underbody, including the floor, is connected to the frame and itself via bonding and screws.

In the August issue of CW, we’ll continue covering composites innovation on the new Corvette, resuming with additional components at the body structures level and finishing with exterior closures (body panels), plus additional trim and upgrades. See Part 2.

Related Content

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreRead Next

Corvette: A multi-material success history

At the launch of the 2020 C8, Columnist Dale Brosius reflects on the iterations of multi-material innovation in the manufacture of Corvettes over its history.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)