Composites Recreate Ultimate Alien

Largest-ever theme park ride icon comes to life in glass/epoxy laminates.

When Universal Studios (NBC Universal, Hollywood, Calif., U.S.A.) envisioned a ride based on its Men in Black (MIB) movie series for its Orlando, Fla., U.S.A., theme park, Cinnabar California Inc. (Los Angeles, Calif., US.A.) got the nod to design and build the largest architectural icon ever produced for a theme park.

Cinnabar is in the business of creating and building unusual facades and architectural icons for theme parks, sets for stage, film and TV, museum exhibits, three-dimensional billboards and other specialty structures. Company president David Park explains, "We find solutions for our clients that will give them an artistic finish that is engineered to last."

Men In Black challenge

In the Men in Black science-fiction comedies, lead actors Tommy Lee Jones and Will Smith play ultra-secret agents assigned to track and control a sizable alien immigrant population from other planets. The theme park ride takes park guests through simulated New York City streets, where they are stalked by a series of unfriendly aliens, including the biggest, baddest of them all in the final ride sequence.

Dubbed "the bug" and called "the ultimate alien" by Cinnabar's technical director, Charles Dore, the massive mechanically animated creature stands 12.2m/40-ft tall and hovers 16.8m/55-ft wide, belching smoke over the ride's car tracks. The six-eyed bug gets no holidays: it has been in continuous motion for 12 to 15 hours a day, 365 days a year for four years, and Cinnabar guarantees its performance for six more.

The MIB icon presented Cinnabar with a multifaceted challenge: produce a lightweight structure that would not only meet requirements for durability and safety, but conform to exacting mechanical and artistic demands as well. Although a urethane foam substructure with a urethane hardcoat could have fulfilled artistic and weight requirements at low cost, Dore notes that the material lacks durability and cannot achieve the theme park's specified Class A fire rating, with Class I flame spread and smoke requirements (ASTM E-84 "Standard Test Method for Surface Burning Characteristics of Building Materials," ASTM International, W. Conshohocken, Pa., U.S.A.). "Only fiberglass composites met all requirements," says Dore, although he notes that fire officials initially expressed reluctance to allow resin in the structure. However, Vipel K022-AAA-00 corrosion and fire retardant Bisphenol A epoxy vinyl ester resin from AOC LLC (Collierville, Tenn., U.S.A.) was finally accepted as a fire-safe matrix and adhesive.

Creature features

The creature's body would be anchored to a concrete base and steel support structure. Moving parts - the bug's 9.1m/30-ft long claw, which swings down in a 90Int arc to threaten approaching riders, and its 6m/20-ft diameter head, subject to compound motion as it swivels - would be thin composite "skin" shell structures attached to articulating devices made from steel tubing and driven by computer-controlled actuating mechanisms. Each shell would have to support its own weight in the spans between attachment points with a safety factor of five, the standard for loads overhead of personnel.

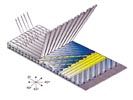

A significant design challenge was presented by the composite-to-steel interface between the bug's irregularly shaped composite "skin" and its steel "skeleton." Cinnabar's solution was notable for its simplicity: The fiberglass shells would be attached to structural composite beams, or stringers, which, in turn, could be mechanically fastened to the articulating arms when the bug's body parts were delivered to the ride site. The use of threaded inserts in the stringers was judged unreliable for the fatigue service. Instead, stringers were to be through-bolted to steel straps which would be connected to the steel tubes of the articulating arms at the ride site via an adjustable armature, consisting of a turnbuckle and steel rods (see illustration, at left). A torsion wrench would be used to correctly position and tension the parts, after which each turnbuckle would be wired to prevent loosening.

Ten years or 10 million cycles

A related challenge involved structural fatigue of the thin fiberglass laminates that would provide the "skins" for the claw and head. To determine the laminate properties that would be sufficient to resist fatigue, Cinnabar first built a scale model (1 inch to 1 ft) of the entire ride layout, including the "bug" and other features, from which a digital solid computer model and drawing were developed. Then Dore sought the expert advice of Robert A. Schofield, Naval Architect (Melbourne, Fla., U.S.A.). Based on Cinnabar's mathematical model, Schofield technicians performed structural analysis of the moving parts, using the Schofield-developed CLAM composites stack ply laminate analysis program. The laminate data was imported to CosmosM finite element analysis (FEA) software from Structural Research & Analysis Corp. (SRAC, Los Angeles, Calif., U.S.A.) to determine the long-term fatigue strengths and time-based modulus (tendency to creep) for the anticipated 10 million animation cycles during the structure's 10-year service life. Loads were primarily bending loads, with a few columnar loads, says Schofield. Loads on the moving head were inertial loads only, imposed by the mass of the laminate.

Based on Schofield's analysis, Cinnabar determined that stitched nonwoven glass fabrics would function best in this application. Their greater tension and compression properties lend them better fatigue performance than woven fabrics, especially in applications where moving parts can cause wovens to crimp and fray.

A final design consideration was maintenance. "There are lights and other things that have to be changed throughout this creature," Park points out. "We had to plan for people to be stepping on unexpected places." For example, the extension of the head's lower jaw is not supposed to be a platform, but was designed to be man-rated, just in case. For this reason, in addition to the quadraxial fabric used in the standard laminate schedule, four additional biaxial plies would be applied to build up the lower jaw.

Alien anatomy

Fabrication took place near the theme park site, at Cinnabar's Orlando production facility. The computer model was used to create instructional code for the CNC machine that routed basic shapes from urethane foam for the creature's head, claw, teeth and body molds. The resulting partially sculpted foam was finished by hand to refine the imagined lumps and bumps of a scary creature from outer space. With the exception of the creature's teeth, the foam forms became the molds for each part. (Unlike conventional composite molding, where the molded part takes its shape from contact with the mold surface, the creature's external features were layed up over the foam molds, with the visible portion on the outside.)

For the layup, Cinnabar selected Vectormat stitched (binder-free) chopped strand mat and Vectorply LTM biaxial and QXM quadraxial nonwoven fabrics made by Vectorply Corp. (Phenix City, Ala., U.S.A.) using E-glass fibers from PPG Industries (Pittsburgh, Pa., U.S.A.). Designed with integral chopped glass mat layers on one side to promote interlaminar adhesion, LTM and QXM are made by scattering chopped 2-inch glass fibers over the oriented fiber layers, then stitching them all together with polyester yarn in a single operation. Trevor Humphrey, vice-president of operations for Vectorply, says, "The binder-free mat enables the manufacturer to wet out the product much faster and obtain higher glass-to-resin and strength-to-weight ratios."

For the claw, the 8.4-mm/0.33-inch thick skin consisted of a layer of 628.5 g/m2 (18.54 oz/yd2) Vectormat E-M-0020-7, laid down first against the foam mold; six plies of 1,562.80 g/m2 (46.09 oz/yd2) Vectorply E-LTM 3610-7, a 0°/90° biaxial fabric with 305 g/m2 (9 oz/yd2) mat layer, followed by an outer layer of Vectormat for better aesthetics.

The ply schedule for the 6.35-mm/0.250-inch thick skin of the bug's head consisted of a layer of Vectormat followed by four plies of 1,180.30 g/m2 (34.81 oz/yd2) Vectorply E-QXM-2608-10 (0°, +45°, 90°, -45°), with a 275 g/m2 (8.1 oz/yd2) mat layer, and an outer layer of Vectormat.

Using the same ply schedule, the alien's teeth (the largest 3.5m/11.5-ft long) were made separately in two-piece open molds.

To cover the static concrete portion of the bug body, Cinnabar hand layed laminate facades featuring chopped strand mat followed by a layer of QXM fabric, with the mat side down for better adhesion, topped off with a decorative sprayup of resin and chopped glass.

After the parts were laminated and cured ambiently for two to seven days, depending on the size and mass, molds were removed and parts were postcured at 93.3°C/200°F. Postcure can take from several hours to several days depending on the part, Dore says, to "provide the ultimate in physical strength and rid the laminate of any unreacted styrene." Cinnabar's largest oven handles parts up to 11m by 4.9m by 5.5m (36 ft by 16 ft by 18 ft).

Head and claw stringers were molded using seven plies of biaxial fabric. Cured stringers were cut with a diamond blade to approximate the shapes of the interior (underside) surfaces of the skin laminates and allow about 305 mm/12 inches between the stringer and the steel tubing of the articulating arms. Stringers were positioned in the shells perpendicular to the skin's inside surface with a 9.525-mm/0.375-inch gaps between skins and stringers, then four plies of biaxial fabric were draped over the stringer at 2-inch intervals, forming hat structures that were bonded to the skin using the Vipel resin. Four identical doubler plies of biaxial fabric were laminated over the top of each cured stringer and about 12 inches down each side where bolt holes would be drilled, to take shear and tensile loads.

As the finishing touch, Cinnabar then applied to all visible "skin" surfaces a thin (3.8-mm/0.15-inch) film of Class 1 vinyl ester syntactic fire-retardant foam from HK Research Corp. (Hickory, N.C., U.S.A.). The foam was sanded smooth, and a coating of HK's UPE surfacing primer was sprayed over the foam as a base for final decorative painting with Class A fire-retardant coatings. "We had not less than 10 scenic artists working on the finish of the alien at one time," Dore notes.

And on to the next project …

Since the bug, Cinnabar has fashioned roller-coaster-type cars for Spiderman rides at University Studio's theme parks in Orlando and Osaka, Japan, a 36.6m/12-ft high elephant (on its way to Missouri, U.S.A.), rock-climbing walls and, in a change of pace, a support and enclosure for laser eye surgery instruments - all from composites. Although the company uses carbon, aramid, polyester and S-glass fiber reinforcements when specified, its engineering team finds that 99 percent of its structures - despite their unusual natures, varied functions and the array loads they must bear - can be manufactured using E-glass in multiaxial fiber architectures.

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)