Composites upgrade marine infrastructure

All-composite docks best concrete in cost and time and aim toward future fastener-less construction for greater savings and sustainability.

In 2007, the St. Johns River Bar Pilots, who ensure the safe navigation of ships in transit between open seawater and the Port of Jacksonville, FL, US, needed to replace the T-head for the pier used to dock its two 22m-long pilot vessels. Licensed by the US Coast Guard and the State of Florida, the St. Johns Pilots assist local, state and federal authorities with seaport development and port security.

The crumbling concrete structure that had formed the T-head for 26 years actually collapsed into the river while final details for its replacement were still under discussion. At that time, the Pilots chose an all-composite system for the new dock. Designed and installed by Register Marine (Jacksonville, FL, US), it included glass fiber-reinforced composite pilings, structural frames and deck, all joined with methyl methacrylate adhesive as well as stainless steel bolts and fasteners. The new composite dock was designed to withstand 74-95 mph winds, per Category 1 hurricane requirements, as well as to provide enough energy absorption to prevent damage to the pier structure as the pilot vessels dock.

So it was that at the end of 2011, when the city of Jacksonville needed to create new marine infrastructure just upriver of the Pilots Pier near the mouth of the St. Johns River, that earlier experience helped Register Marine offer a solution to a much more demanding dock design.

Category 3 capability

Through the Jacksonville Port Authority, the city had federal funding via a Homeland Security grant to build a new facility that could survive a Category 3 hurricane and then offer immediate response as the storm receded. The result, Jacksonville Fire & Rescue Department (JFRD) Station 40, had been built not only to sustain Category 3 forces — 205-241 kph winds and 2.74-3.66m of sea storm surge — but also to provide shelter for emergency response crews and dozens of storm refugees. JFRD had purchased a new 22m fireboat boat, Marine One, which would be permanently moored at Station 40 on a new 22m by 2.4m floating dock. Additionally, a 67m long by 1.8m wide fixed portion of the new dock structure needed permanent lifts for a 9.14m fireboat and two same-sized Port Authority security boats.

“The first bids to build the dock with reinforced concrete were rejected because they were too expensive,” explains Register Marine president George Register. With all bids 50% over the budget, and no viable alternatives, the city believed it would have to forfeit the grant money and abandon plans for the new dock construction. But then Register found out about the project and met with city engineers. “We reoriented the program to use composites,” he says, “and were able to meet all of the technical and grant-funding requirements, including budget and timeline.”

Saving weight, waste, cost and time

“Designing a dock isn’t rocket science,” concedes Register, explaining that the basic components of pilings, decking and a means to connect these are pretty universal. That said, Register explains that each dock must be designed for its unique loads

and environment. “The Station 40 design cannot just be copied,” he adds.

Register had been working with pultruded composites in marine construction for years, including fiber-reinforced plastic (FRP) pilings, channels and decking. For the St. Johns docks, Register worked with Stuart LaHaise, president of Composite Products Plus (Jacksonville, FL, US) and a manufacturer’s representative for ACRA-LOCK methyl methacrylate (MMA) adhesive made by Engineered Bonding Solutions LLC (Titusville, FL, US).

He explains, “We developed a system where all of the composite pultrusions are held together using both ACRA-LOCK structural adhesive and stainless steel through-bolts.” In the future, Register would like to eliminate the use of stainless steel fasteners, but for now, they provide structural redundancy and, for that reason, were necessary to appease the structural engineer on the project.

Register Marine went through a rigorous design process, working with structural engineer Dan Charletta of Structures International LLC (Jacksonville, FL, US), while Dr. Bill Miller, senior coastal and hydraulics engineer at Taylor Engineering (Jacksonville, FL, US), completed the numerical modeling and storm force predictions. “It was important that Dan was amenable to FRP,” says Register.

The real challenge for the Station 40 dock was to meet hurricane requirements, corrosion resistance, energy absorption and environmental regulations without exceeding the very tight cost and timeline demands, which are common for such projects. “Because composites weigh so much less than concrete,” explains Register, “our all-composite approach was much more cost- and time-effective vs. traditional materials.” For example, Register Marine was able to build deck support sub-assemblies off site and deliver these to the build site prefabricated. This reduced onsite construction and shortened installation time. “We also offer much better waste control — our waste has been only 1-2%,” Register notes. He adds that with composite dock systems, there is nothing that leaches out into the water.

Pilings, bents and bays

For the fixed pier portion of the Station 40 dock, Register Marine used 356-mm outside diameter (OD) pultruded glass fiber-reinforced polyurethane tubular pilings supplied by Creative Pultrusions (Alum Bank, PA, US). These were installed on a batter — that is, an angle calculated to improve the piling’s ability to carry lateral loads (see Step 1, at left). Pilings were placed using a standard, barge-mounted pile driver with a hybrid drop/vibrating hammer. Dock pilings are driven in to a depth specified by the structural engineer to achieve the required bearing load, which is calculated from the expected axial and radial loads on the pilings. The pilings then were cut to the prescribed height using standard woodworking tools equipped with carbide or diamond blades/tips.

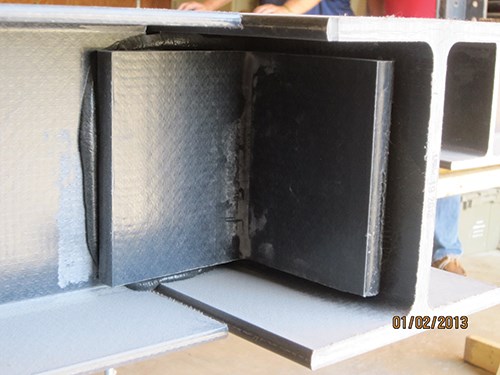

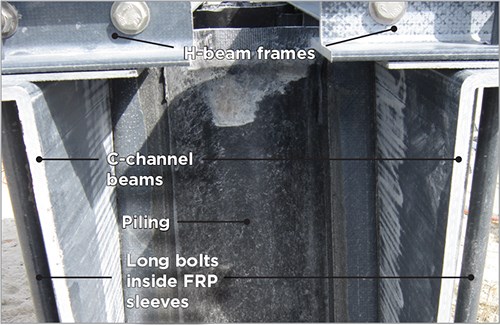

While the final pilings were being driven in, 610-mm-wide pultruded C-channels — again supplied by Creative Pultrusions, but this time formed from glass fiber-reinforced polyester — were bonded to the pilings using ACRA-LOCK adhesive. Once the adhesive set (10-15 minutes), the C-channels and hollow pilings were drilled, and stainless steel through-bolts were installed to tie them together and redundantly reinforce the joints (see Step 2). Thus, the vertical structural elements — called bents in standard bridge and dock terminology — each comprised two 610-mm C-channels and two pilings.

The horizontal framing and decking that span the bents are called bays. Before piling installation began, construction of the bays was already in progress at the Register Marine facility. Rectangular frames, 3.7m in length, were assembled from 152-mm-wide flange composite H-beams (glass/polyester from Creative Pultrusions) with two central cross-members spaced on 1.2m centers (Step 3). At each intersection of two H-beams, pultruded glass/polyester angles (L-sections) were bonded into the interior corner using ACRA-LOCK (Step 4). This was followed by drilling of through-holes and installation of stainless steel through-bolts (Steps 5 & 6). The H-beam intersections then received pultruded glass/polyester plates, measuring 6.4 mm thick, which were bonded onto the top and bottom of the frames. Both the interior angles and top and bottom plates were used to compensate for the anisotropy of the pultrusions. The completed frames (Step 7, p. 65) were then transported to the dock construction site, ready to install over the vertical bents.

As bents were completed and ready to receive a bay section, ACRA-LOCK was applied to the tops of the C-channels and a frame was placed between two bents, aligning each end on top of a C-channel (Step 8). Then holes were drilled through the reinforcing plates, H-beam flanges and C-channel flanges. Stainless steel long bolts, encased in protective FRP sleeves, were installed through these holes, attaching the bay frames to the C-channels (Step 9). This process was completed until the fixed dock was ready to receive the composite decking (Step 10).

Decking and completion

Although FRP decking is a standard Creative Pultrusions product, engineers had determined that the Station 40 decking should have 50% of its surface area open for dispersion of uplifting forces during storm surge waves. This helps the dock to meet Category 3 hurricane standards, and also allows sunlight to shine through, enabling sea oats and other anchoring grasses to grow beneath for coastal conservation. Creative Pultrusions worked with Register Marine to specify a glass/polyester pultruded deck panel that would meet the project’s requirements.

The 1.2m long deck sections were attached to the frames using 50.8 mm by 25.4 mm stainless steel clips with through-bolts that achieved a blind connection into the frame flanges (Step 11). “The number of clips needed and their spacing was calculated by the structural engineer to counter the uplifting force from waves after being dissipated by the 50% open surface deck grid,” explains Register.

As decking was being installed on the fixed pier, vertical pilings (not on a batter) were installed for the three small boat hoists. These smaller, 305-mm OD pilings were manufactured by Harbor Technologies (Brunswick, ME, US) using 107-oz glass fiber woven roving and 8084 polyester resin from Polynt Composites USA (previously CCP Composites, N. Kansas City, MO, US). The actuated hoists were then finished and topped with standard fiberglass planking while the floating dock was constructed using the same structural elements and decking as the fixed dock.

Register Marine met every deliverable specified in the contract, with five days to spare in the construction timeline. The project as a whole, including design and permitting, was completed in 16 months. Actual dock construction took only six months and was completed in April 2013. “Jacksonville Fire & Rescue Department is very pleased,” says Register, “and the dock has performed exactly as programmed and designed.”

Fastener-less future

Although the Station 40 project is considered an unqualified success, Register nevertheless sees room for improvement. “This design used pultruded components, which typically only have strength in the axial direction,” he notes. “We had to overcome this weakness through design.” Register has begun working on the next generation of composite dock systems with president Jeff Gray and project manager Dana Greenwood at Vectorworks Marine (Titusville, FL, US).

“By replacing off-the-shelf pultrusions with our own manufactured components, the C-channels and frames can be fabricated to have strength in all of the directions necessary for each design, tailored for the required performance and durability while minimizing weight.” Register explains that with pultrusions, “you simply replace wood, concrete or steel,” but this new development team wants to engineer the composites to take advantage of the benefits they offer, including the ability to use fire-retardant resins, electrical current insulation and 100% bonded construction, using structural adhesive to eliminate fasteners.

According to Register, stainless steel fasteners comprise 10% of his company’s current dock construction costs. “The development of an adhesively bonded construction without fasteners will not only reduce cost but also bring all components to the same material and service life,” he says. “The life of the composite parts is much longer than that of the stainless steel hardware in the marine environment.” He notes this bonded construction also will enable innovative design and assembly ideas that will minimize the number of structural components and many of the awkward installation details currently required to complete a project. The result will remain a very robust marine structure, but one with a more elegant design and more efficient construction process. “All of our projects are ‘design-build’ in order to ensure performance,” says Register, “but now they will be ‘design-build and manufacture.’”

Register also is seeking an additional advantage by designing prescribed energy absorption capacity into dock structures, which is expected to improve the durability and service lives of the docks and the marine vessels that use them “We have already demonstrated that we can compete with concrete,” says Register. “Now we are taking this technology to the next level.”

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)