Covestro kicking the tires on polycarbonates for automotive

Although development work has only just begun, the company's Makrolon polycarbonate, in a carbon fiber-reinforced composite, is proving highly impact resistant and offers a Class A surface.

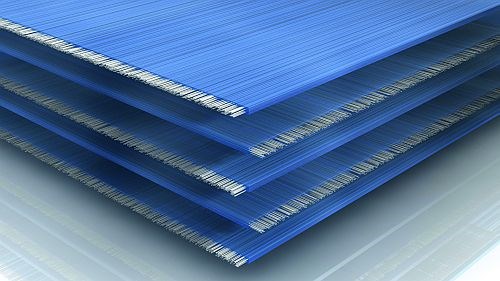

Covestro LLC is in the early stages of developing a carbon fiber/polycarbonate composite material for application in first-surface interior and exterior automotive parts. The blue color is meant to show a breadth, not a limitation, in color and polymer possibilities.

SOURCE: Covestro LLC.

Paul Platte, senior marketing manager automotive and transportation at Covestro LLC (Pittsburgh, PA, US), spoke at CompositesWorld’s Thermoplastic Composites Conference for Automotive in Novi, MI, US (June 15-16) and revealed that the company is assessing application of carbon fiber/polycarbonate composites in first-surface exterior and interior automotive structures.

Covestro’s research is still in early stages, Platte said, but what he reported is promising. The company is working on development of thermoformable Makrolon polycarbonate tape or sheet products, ranging from 0.5 to 1.7 mm thick. Finished parts are “expected” to produce a Class A surface, would have properties similar to aluminum and could, said Platte, be used to fabricate automotive body panels. Tests, Platte said, show that the material can withstand up to 47J of impact energy, and it has passed the UL94 test for flammability.

Other properties of this material include a 1.5 specific gravity and low thermal conductivity — although Platte noted that carbon fiber-reinforced polycarbonate is 10 times more conductive than unfilled polycarbonate. This material would have to be coated to protect against UV exposure, and it is not, said Platte, compatible with the E-Coat plating/painting process.

Covestro’s work has focused mainly on use of carbon fiber reinforcement, but glass fiber will also be developed. The company is also researching a variety of polymer blends and assessing what is of value and interest to the market. In addition, the material can be backmolded (i.e., with ribs) to provide additional reinforcement. Platte said the company expects to see polycarbonate composites in consumer products by 2018-2019, and in vehicles by the early 2020s.

Covestro’s work on polycarbonate composites has grown out of technology acquired when the company bought Germany-based Thermoplast Composite GmbH in March 2015.

Related Content

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

.jpg;maxWidth=300;quality=90)