Share

Shape Corp. is the first company in the Americas to own one of TTI’s radius pultrusion lines. Source | Shape Corp.

Pultrusion is one of the oldest forming processes for thermoset composites and is said to have been the first continuous fiber thermoset forming process. Today, it is used to produce products ranging from utility poles to window frames, as well as ladders, rebar and wind turbine components. Easy to automate with low labor, and capable of producing highly structural components — some quite large — at reasonable cost and speed, traditional pultrusion can produce profiles (hollow or solid, symmetrical or asymmetrical) in nearly any shape that can be squeezed through a die. However, that shape must have a constant cross-section/thickness. Also, unlike thermoplastic extrusion or extrusion of metal tubes and pipes — where pressure and heat can be applied to profiles during production, or afterward to finished parts, to bend them into new shapes — it has been difficult to use pultrusion to produce anything other than straight, linear profiles. That, of course, has limited the use of pultrusion in many industries, particularly in high-volume segments like automotive, which would like to use pultrusion except that there are not many straight beams on cars that would be good candidates.

That’s beginning to change thanks to Thomas GmbH + Co. Technik + Innovation KG (TTI, Bremervörde, Germany), which has developed a patented process to overcome many of the limitations of traditional pultrusion. In fact, the first curved pultruded automotive part has just gone into commercial production with the launch of the 2020 Chevrolet Corvette sports car by General Motors Co. (Detroit, Mich., U.S.) (see the full feature on the Corvette pultruded rear bumper beam). Tier 1 supplier Shape Corp. (Grand Haven, Mich., U.S.) is producing a curved rear bumper beam for the car using TTI’s radius pultrusion moving-mold process in carbon fiber-reinforced polyurethane-acrylate.

Here’s why that’s a big deal.

Moving vs. stationary

In conventional linear pultrusion, a reciprocating pulling system with grippers is used to draw dry reinforcements from their creels, through a bath where they are impregnated with liquid thermoset resin. Next, the impregnated reinforcements are pulled into a stationary heated die where the profile is shaped and fully cured. Upon exiting the die, the moving profile cools (still being drawn along by the pull-off unit) and then is cut to length and packaged.

Initially, fiber reinforcement was limited strictly to unidirectional rovings — in other words, continuous glass, carbon, or other fibers oriented 0 degrees to the axis of pull. However, over time a variety of multiaxial fabrics — both weaves and non-crimp fabrics (NCF) — have been incorporated into pultruded profiles, enabling a range of fiber orientations without distortion/fiber movement. Nearly any thermoset resin system can be used to impregnate reinforcements in pultrusion, although a significant amount of applications use polyurethane. In recent decades, pultrusion has even been modified to allow use of prepolymerized thermoplastics.

Many features of conventional pultrusion have been turned upside down in TTI’s radius pultrusion process, but the most important aspect to understand is that with radius pultrusion, the die isn’t stationary; rather, it moves and pulls material to create either a linear constant cross-section or a constantly curved profile.

The die, or a series of dies, not only moves back and forth over the profile, shaping and curing the material while both advance along a track — in this case with the profile moving in a single direction and the die moving in both directions — but the die also pulls the dry reinforcements through the resin bath and the cured profile along toward the grippers and cutter. To produce a linear cross-section, both mold and profile move along a straight section of the track; to produce a curved cross-section, the mold and profile move along a curved section of the track.

TTI’s radius pultrusion equipment allows the machine axis to be rotated either horizontally or vertically, making it possible to produce a profile with a continuous curve and a constant 2D or 3D radius, or alternating straight and curved sections, or, more remarkably, a profile that looks like a coil spring.

“In this technology, the die effectively replaces the reciprocating puller, which is replaced by stationary grippers that open and close but don’t otherwise move,” explains Sebastian Mehrtens, TTI head of sales. “The grippers close and support the cured profile when it reaches a pre-specified length and is ready to cut, but otherwise remain open and let the profile move toward the cutting unit.” To reduce risk of fiber pullout from the hot material, heated dies are chrome plated.

Additionally, TTI’s radius pultrusion equipment allows the machine axis to be rotated either horizontally or vertically, making it possible to produce a profile with a continuous curve (hoop structure) and a constant 2D or 3D radius, or alternating straight and curved sections, or, more remarkably, a profile that looks like a coil spring. “When the curved section occurs parallel to the long [pulling] axis, rotation and linear [pulling] movement are vertical, which is to say that they curve up or down, as in the case of a bumper beam,” explains Jens Bölke, TTI head of composites and new technologies. “On the other hand, when the curve occurs parallel to the short [cross-pulling] axis, rotation and linear movement is horizontal, which means that it curves left or right as in the case of a window profile for a glass-topped sunroof system.”

The main design limitation that radius pultrusion has at the moment is that it’s not yet able to produce profiles that are both curved and have a variable cross-section. A couple of other practical limitations are that while there is no theoretical limit to the maximum radius, the largest TTI has produced is 1,500 centimeters in diameter and, in the case of a coil spring-like structure, the maximum radius is presently 40 millimeters. Several years ago, the company noted that future work in radius pultrusion would focus on producing curved wave-spring structures and possibly venturing into thermoplastic profiles via reactive polymerization.

Benefits and application possibilities

There are many advantages to radius pultrusion:

- It operates at roughly the same speeds as conventional linear pultrusion (up to 2 meters/minute).

- It generates little scrap.

- It can produce solid or hollow structures with high fiber volume fractions and 2D or 3D curvatures.

- There is little shrink; profiles exit with low residual stresses and are able to hold tight tolerances.

- Many different resin systems — ranging from polyurethane and epoxy to vinyl ester and unsaturated polyester — can be used.

- Many types of reinforcements, including unidirectional rovings as well as a variety of fabrics — with or without veils for improving surface finish and drapeability — can be used.

In addition to straight or curved bumper beams, which already are in production, other potential automotive applications include roof bows, drivetrain and chassis components, antiroll bars, side-intrusion beams for doors and coil springs. Other markets being targeted include building and construction, architecture, agriculture, marine, infrastructure, medical components and sporting goods. TTI reports that other commercial applications of its technology include use as lost cores during bicycle-rim production.

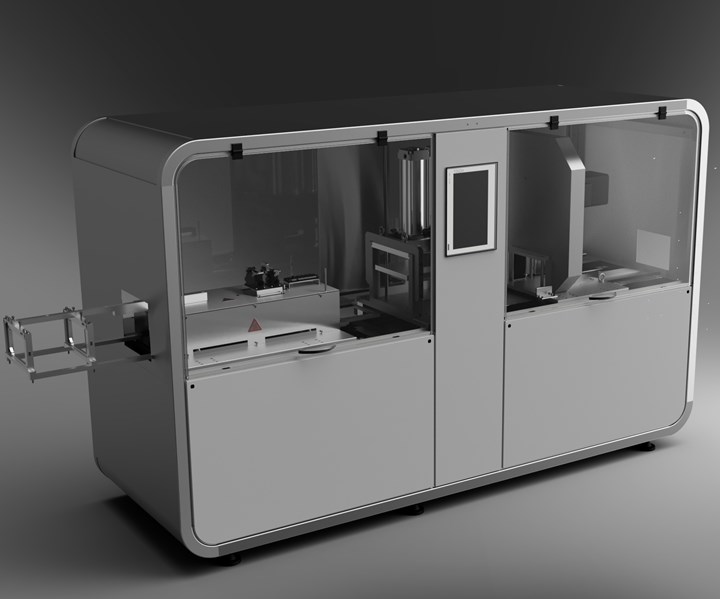

TTI currently builds and sells radius pultrusion equipment, licenses the process and produces conventional linear and radius pultruded parts for customers. TTI's newest innovation is its pullCUBE system, which was originally set to be launched at JEC World 2020 and now will be presented in live, online sessions in May (dates available at www.pullcube.de). Said to be the world’s shortest pultrusion equipment at 3.5 meters (versus conventional pultrusion machines, which can be 15-20 meters long), the compact system can produce straight and curved profiles on the same machine and comes equipped with a mold, gripper unit and cut-off saw. “Since it’s 75% shorter than conventional pultrusion equipment, pullCUBE uses significantly less energy during operation and generates 75% less dry fiber waste during initial setup,” adds Bölke. “Also, unlike conventional pultrusion systems, which require a purge of material roughly every 15-30 minutes during production, our new equipment doesn’t require a purge cycle at all during normal production runs.”

The newest technology from Thomas GmbH + Co. Technik + Innovation KG is the company’s pullCUBE compact pultrusion machine. Said to be the world’s shortest pultrusion system, the equipment is 3.5 meters in length — 75% shorter than conventional pultrusion lines that can be 15-20 meters long — and can produce straight (conventional) or curved (radius) pultruded parts. The unit’s diminutive size contributes to significant savings in energy, dry fiber waste, shipping costs, and warehouse space; it doesn’t require regular purging throughout the production process, further reducing resin and fiber waste; and the fully-enclosed design helps increase worker safety. Source | Thomas GmbH + Co. Technik + Innovation KG

Furthermore, the diminutive system is far easier to ship, can be moved with just a forklift, is faster to set up than conventional lines and requires far less space on a plant floor. “This could have interesting benefits in some applications,” notes Mehrtens. “For example, the machine could be set up near a bridge renovation to produce structural elements as needed. Or, it could be set up as new highway was laid and could produce rebar that could be cut to custom lengths right at the job site.” Still another advantage of pullCUBE is worker safety, since the unit is fully enclosed and operators won’t burn hands on hot mold surfaces or be pinched by grippers or cut by the saw.

Related Content

Industrial equipment manufacturer expands global footprint, reaches into new markets

India-based CW Top Shops honoree EPP Composites reflects on a recently successful vertical filament winding application and new pultruded FRP rebar capabilities, as well as future opportunities.

Read MoreSeat frame demonstrates next-generation autocomposites design

Light weight, simplified/cost-effective manufacturing, passenger comfort and safety informed materials and process innovations and won awards for the 2022 Toyota Tundra‘s second-row seat frame.

Read MoreExel Composites pultruded rods enhance Umbrosa parasol durability

The Belgium-based manufacturer chose pultruded fiberglass ribs for many of its umbrella and parasol designs to effectively endure exposure to high wind speeds, saltwater, rain and UV.

Read MoreServo-based pultrusion machines for composite profile production

CAMX 2023: Kent Pultrusion is displaying its turnkey ServoPul servo-driven pultrusion lines and secondary equipment for handling composite profiles.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;width=70;height=70;mode=crop)