ClockSpring|NRI provides composite strengthening solutions for pipelines and other critical infrastructure applications. Photo Credit: Global Shop Solutions

ClockSpring|NRI (Riviera Beach, Fla., U.S.) engineers, designs and manufactures composite strengthening systems to restore, protect and reinforce pipes, pipelines and civil structures. The company works with moisture-curable carbon fiber, fiberglass, Kevlar and other aramids, and serves a range of markets, including construction, industrial, marine, military, mining, municipalities, offshore, oil/gas and refining/petrochemical.

From leak repair and pipeline integrity solutions to corrosion protection, corrosion repair, coating repair and mechanical reinforcement, ClockSpring|NRI says its solutions help restore and protect degrading or failing assets at a fraction of replacement costs. In addition, the company can retrofit and reinforce defects and anomalies to original specifications, and can repair and reinforce pipelines or civil structures while they remain operational, reportedly saving clients millions of dollars in costs and lost revenues.

In 2012, company leaders recognized a need for a comprehensive business management system, as the system they were using offered little more than basic inventory management and financial capabilities. With this old system, determining job costs with any degree of certainty presented an ongoing challenge. After reviewing several leading vendors, ClockSpring|NRI purchased Global Shop Solutions (The Woodlands, Texas, U.S.) ERP software in late 2012, and went live in March 2013.

Since then, ClockSpring|NRI can now determine the true cost of every job as soon as the product is completed, thanks to Global Shop Solutions ERP software’s ability to track every aspect of a job — from the cost of raw materials to labor (direct and indirect), machine usage, overhead and more. Important production management metrics such as available capacity, time to complete a job and inventory accuracy can also be determined with precision.

“A large part of my job involves making business decisions based on understanding where our efficiencies and inefficiencies are and how we can improve on them,” Chris Lazzara, president of ClockSpring|NRI, says. “Global Shop Solutions gives us solid data that we can rely on, and it does it in real time. Overall, visibility of data is by far the biggest benefit we’ve gotten out of the system.”

With Global Shop Solutions ERP software, ClockSpring|NRI can track the entire job quoting process, from customer to conversion. Management can view conversion ratios in a one-standard, all-encompassing format. The ability to see capacity use days or even weeks in advance enables a more proactive approach to managing incoming sales orders. On the purchasing side, visibility of historical costs has dramatically improved the ability to understand and manage gross margins.

“Running the purchase price vantage report allows us to see what we bought a part for in the past and what it costs now,” Jordan Griffith, VP of operations, explains. “This helps us make better purchasing decisions and gives us a much clearer picture of our gross margins. With Global Shop Solutions, we can narrow gross margins down not just to product lines or categories, but to individual products. That way, we can understand our efficiencies and either change our manufacturing methods or reduce inefficient products and focus on higher margin products.”

In addition, the software integrates quality management into the job production process. Lazzara says, “We now have increased visibility around the true cost of quality to our organization. Not just what it costs to remake a part, but our total cost of quality. Which means we now know what we’re really spending to manufacture our products. In the past, we could track scrap and things like that, although not as accurately as we do now. But until we got Global Shop Solutions, we could not determine overall cost of quality.”

The ability to track job performance data has also assisted with the development and implementation of a three-tiered bonus program for production workers to further boost productivity. The tiers measure quality, reliability and integrity, respectively. When workers hit performance goals in all three tiers, they receive a bonus at the end of the month.

As senior managers, Lazzara and Griffith make extensive use of Global Shop Solutions ERP software’s Dashboards, which provides a quick, high-level snapshot of the company at any given time.“In addition to Global Shop Solutions’ robust capabilities, we really liked the simple, intuitive user interface,” Lazzara says.

Efficiency and cost of production are key in today’s fiercely competitive manufacturing markets, Lazzara and Griffith agree, which depends on visibility of data.

“Having good visibility of our margins has allowed us to identify and focus on our core competencies,” Lazzara adds. “That, in turn, has enabled us to simplify our offerings in the market to 10 to 15 products. We still accommodate customer needs beyond those core products. But now we can educate the customer on what it will cost before we take the sale, and then let the customer decide whether or not to make the product.

“At the same time, the efficiencies we have developed through Global Shop Solutions allow us to reinvest more money in the business,” he concludes. “The more we deploy resources to their best and highest use, the more we can grow the business. The visibility of data in Global Shop Solutions allows us to determine where to invest our money to grow the business and get the best return on that investment.”

Related Content

Urban furniture project demonstrates green potential for composite 3D printing and recycled materials

Large-format AM specialist Caracol and partners designed custom, 3D-printed outdoor furniture with glass fiber-reinforced recycled polypropylene, and conducted an LCA to evaluate and improve the process.

Read MoreComposite materials, design enable challenging Corvette exterior components

General Motors and partners Premix-Hadlock and Albar cite creative engineering and a move toward pigmented sheet molding compound (SMC) to produce cosmetic components that met strict thermal requirements.

Read MoreBio-based epoxy, recycled materials increase sustainability of all-terrain snowboards

Aiming for a smaller environmental footprint while maintaining high performance, Salomon’s Highpath snowboard line incorporates bio-based epoxy, glass and basalt fiber stringers and recycled materials.

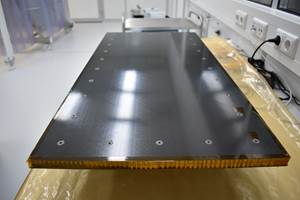

Read MoreNanomaterials optimize performance of space-ready carbon fiber composite panels

A recent ESA project led by Adamant Composites aimed to mature nanomaterial-enhanced CFRP for lighter weight, more thermally and electrically conductive materials for manufacturing satellite structures.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)