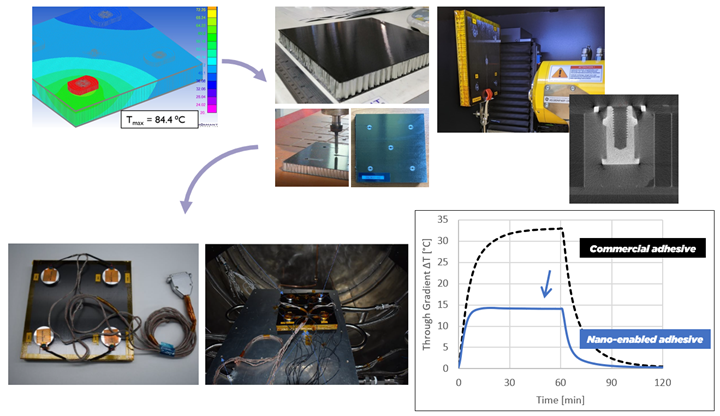

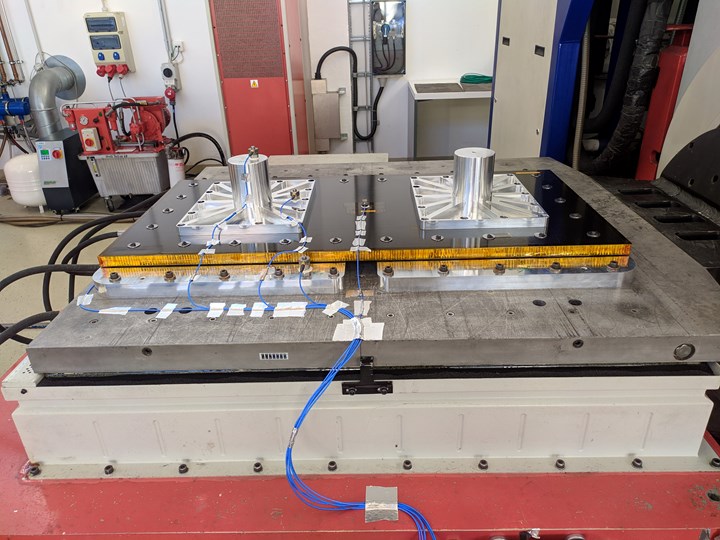

The HITEC project aimed to mature materials and manufacturing technology for producing thermally and electrically optimized, nanomaterial-enhanced carbon fiber composite sandwich panels for use on space structures such as satellites. Graphene-enhanced prepregs and adhesive were both developed, used and tested during the program. Photo Credit: Adamant Composites, via ESA

Adamant Composites Ltd. (Patras, Greece) was founded in 2012 with the goal of translating academic research on nanomaterial-enabled composites into real-world applications. Recently, this work has included a linerless liquid oxygen (LOX) tank, and a partnership with graphene producer Levidian (Cambridge, U.K.) to develop new graphene-enhanced composites products.

Adamant Composites also recently undertook a 3.5-year research project with the Materials and Processes division of the European Space Agency (ESA, Paris, France), aimed at maturing nanomaterial and graphene-enhanced composite technologies for qualification in satellite structures.

One challenge in designing space structures such as satellites is that in space, temperature conditions vary widely. For example, at any given time, part of a satellite’s surface may be subjected to hot, direct sunlight, while the other half is pointed away from the sun and subjected to cold, airless shadow. The vacuum of space is also highly insulating, which can lead to potentially damaging electrical charge buildup on the satellite’s surface.

Traditionally, satellites have been made from conductive metals, but as these materials are replaced with stronger, lighter weight, less conductive carbon fiber-reinforced polymer (CFRP) materials, the likelihood of thermal or electrical buildup becomes greater, which can lead to damage such as surface buckling, warping and more.

Therefore, to protect both the satellite surface and interior equipment, measures need to be taken to minimize buildups by dissipating heat and electricity more evenly across the surface and through the part. There are several solutions available today, such as the addition of heat-conducting metallic pipes, wires or strips to provide conductive paths over the satellite’s surface. These, however, add additional weight and material to the part, minimizing the advantages of switching to CFRP.

In project HITEC (High Thermal and Electrical Conductive Bonding Materials for Space), which began in 2019 and concluded in fall 2022, Adamant Composites and ESA sought to tune a composite structure for optimized thermal and electrical conductivity without the use of additional conductive tools.

Building on previous fundamental studies performed by Adamant Composites, it was decided that thermally and electrically conductive nanomaterials to enhance CFRP panels would be examined as a potential solution. One advantage to the use of graphene or a similar nanomaterial is that a small amount of the additive can increase certain desired properties to such a significant extent that other materials in the part can be reduced — leading to overall weight savings.

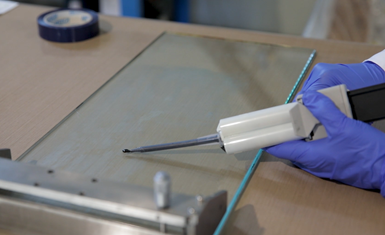

For the HITEC project, Adamant Composites helped develop a graphene-enhanced, electrically conductive adhesive to bond metal hardware to composite panels. The adhesive is now formulated and sold as FXbond by Adamant. Photo Credit: Adamant Composites

Supported through ESA’s General Support Technology Programme (GSTP), the project was designed to evaluate the use of nanomaterials within a carbon fiber/epoxy prepreg material and an adhesive — for joining structural parts and attaching onboard electronics — used to manufacture small-scale prototype satellite panels. Graphene was used within the adhesive, and another proprietary, conductive nanomaterial was added to the prepreg.

“The original idea was to demonstrate a full lifecycle design of a space panel, from design to processing to testing, including new materials such as graphene,” explains Athanasios Baltopoulos, commercial director at Adamant Composites. “The goal was to bring the technology for the CFRP and graphene adhesive up to a technology readiness level [TRL] of 6, meaning it’s qualified to be engaged in an application for launch.”

Adamant Composites designed and manufactured the panels, the Applied Mechanical Laboratory of the University of Patras (Greece) performed materials-level testing and Beyond Gravity (Dresden, Germany) performed part-level testing.

First, the panels were designed via finite element analysis (FEA) modeling, to help understand the needed material makeup based on the load, thermal and electrical conductivity requirements.

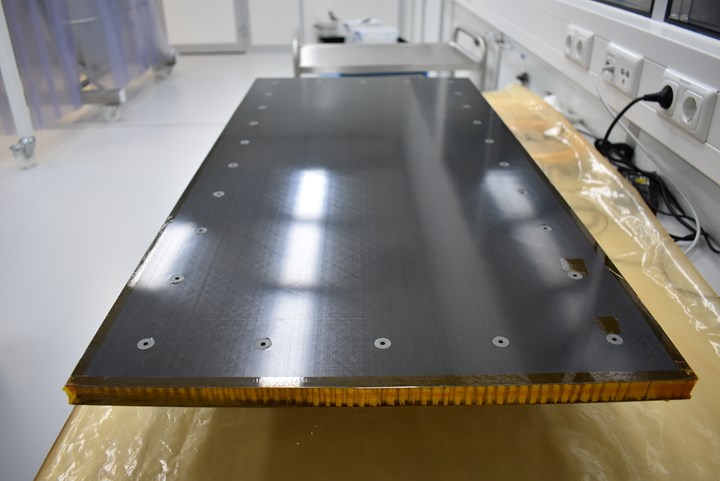

Two 0.5 × 1 meter, 22-millimeter thick CFRP and aluminum honeycomb sandwich panels were manufactured for testing using hand layup and autoclave cure under vacuum — one panel with nanomaterial enhancement, and one without for comparison. Holes were then drilled into each panel and metallic inserts were installed using specially designed graphene-enhanced adhesive.

As a quality control, Adamant Composites evaluated the panels using laser tracking to assess flatness, and a hammer testing technique to evaluate resonant frequencies, and compared the results to the simulations. The panels were further subjected to a variety of tests. For example, IMA Materials Research and Application Technology GmbH performed vibration testing to simulate launch conditions, and Beyond Gravity GmbH performed thermal cycling under vacuum to test strength and durability in space-like conditions.

Thermal sensors were placed on the CFRP skins during testing to track temperature distribution at various temperatures — -22°C, -30°C and 60°C. Along with the testing done to the panels themselves, X-ray tomography was used to evaluate potting quality.

A nanomaterial-enhanced and graphene-free test panel were each tested at the material and parts level, including vibration testing to simulate a satellite launch, shown here. Photo Credit: Adamant Composites, via ESA

The results? Compared to the standard CFRP panel, nanomaterial enhancement was shown to increase electrical conductivity substantially, and also boosted heat propagation with a decrease of the thermal gradient by up to 64% through the panel thickness. Heat was dissipated evenly through the top and bottom skins rather than building up in one area. In addition, the panels were shown to maintain needed structural performance through vibration and thermal cycling tests.

If used in an actual commercial project for space use, the parts could be redesigned further to remove extra conductive elements, enabling a lighter weight, more compact component. After developing materials for this project, Adamant Composites now offers a product line of nanomaterial-enhanced CFRP prepregs called FXply, in which the company adds different kinds of nanomaterials to commercially available prepreg materials, and FXbond, a graphene-enhanced adhesive product.

The HITEC project team started with FEA modeling (top left) which informed the layup of nanomaterial-enhanced CFRP and aluminum honeycomb sandwich panels. Holes were drilled into these and metal inserts installed using graphene-enhanced adhesive (top right). Various testing methods were then performed such as x-ray tomography and via thermal sensors (bottom left). Photo Credit: Adamant Composites

“We had started working on these products before, but through HITEC we really matured the process and product into something repeatable and space-ready,” says Nicolas Blasakis, materials and process engineer at Adamant Composites. “We envision these products on solar arrays, satellites and other space applications.”

Future studies will continue to evaluate how these materials can be used, both on their own and alongside other conductive materials, on their way to ultimately enable lighter, stronger space-ready components. And ultimately, “the goal is to make them fly for in-orbit demonstration and validation, to test these materials’ capabilities in a real space environment,” says Baltopoulos, noting that Adamant Composites is looking for partners and opportunities to continue working on these efforts further.

Related Content

Goodman Technologies develops aligned nanoforest technologies for composites integration

GTNANO ANT, validated through multiple Phase I-III SBIR/STTR projects, are compatible with a wide range of composite materials and processes, demonstrating ILSS, toughness and fatigue resistance.

Read MoreViritech and Haydale pursue new functionalized materials for Type V composite vessels for hydrogen storage

Goal is considerable weight savings via lightweight, impermeable pressure vessels without a liner, further advance in Graph-Pro structural storage tanks with integrated fixation.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreUniversal Matter acquires main operating business of Applied Graphene Materials

UMI aims to combine its graphene capabilities with AGM’s dispersion technologies to accelerate the growth of graphene-based solutions.

Read MoreRead Next

Ultra-lightweight skis demonstrate potential of graphene-reinforced composites

With a graphene additive, Folsom Custom Skis evolved and optimized the material makeup of its carbon fiber composite touring skis for higher performance at a lighter weight.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)