Universal Matter acquires main operating business of Applied Graphene Materials

UMI aims to combine its graphene capabilities with AGM’s dispersion technologies to accelerate the growth of graphene-based solutions.

Universal Matter UK Ltd., a wholly owned subsidiary of Universal Matter Inc. (UMI, Mississauga, Ontario, Canada and Houston, Texas, U.S.), has acquired all shares of Applied Graphene Materials UK Ltd. (Cleveland, U.K.) and Applied Graphene Materials LLC (AGM), the main operating subsidiaries of Applied Graphene Materials plc.

The acquisition took place on March 28, 2023, for a total consideration of $1.3 million USD. The sale and purchase agreements relating to this transaction were signed on February 21, 2023, and UK NSI Act approval was received on March 24, 2023.

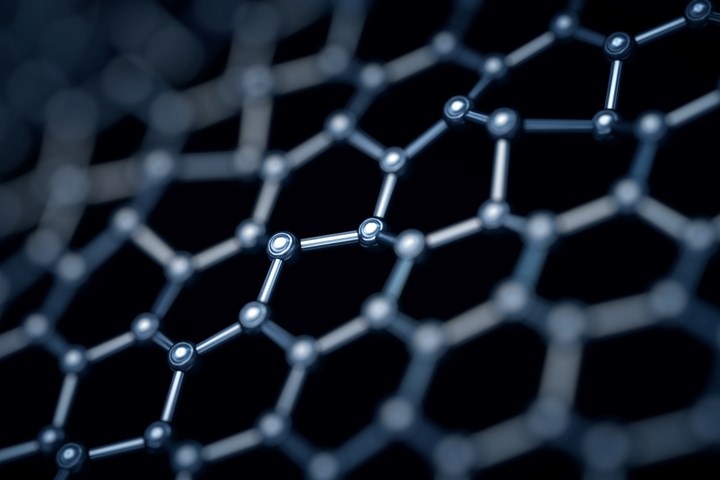

The acquisition aims to accelerate the growth of novel graphene-based solutions by combining UMI’s proprietary graphene capabilities and AGM’s dispersion platform technologies. This combination will also help create a compelling value proposition for many industries by further capitalizing on UMI’s unique flash joule heating (FJH) process for upcycling carbon waste into high-performance, sustainable graphene solutions.

UMI, a privately-held Canadian corporate, was formed in July 2019 and is a high-tech advanced materials company seeking to create strong circular economies by upcycling a range of carbon-based materials, including waste streams, to manufacture and supply high quality and sustainable turbostratic graphene (TG).

UMI’s proprietary flash joule heating (FJH) process can reportedly transform a variety of carbon-containing feedstocks into high value graphene materials using a highly efficient and low-cost manufacturing process. UMI says its unique pathway for producing graphene is strongly protected by background IP and trade secrets that the company has built up during the last three years.

UMI operates its Innovation Centers in Mississauga, Ontario and Houston, Texas. The company has also recently acquired an 18,000 square foot building in Burlington, Ontario for housing its demonstration plant, which is expected to be operational in the third quarter of 2023 with a nameplate capacity of ~1 ton per day at full utilization. The combination of feedstock flexibility and the FJH process technology can produce tuneable graphene products with a range of physical properties.

AGM’s market leading product technologies have been designed to deliver next generation performance requirements for protective industrial coatings and other applications. This includes graphene dispersion technologies, application and formulating know-how, and compelling test results to support market adoption in coatings, composites and beyond. In addition, AGM’s dispersion solutions are said to be easy and safe to use in industrial settings, and have appropriate regulatory approvals for volume deployment.

UMI says that AGM’s dispersion technology will be further leveraged to enable the deployment of graphene materials into many of the strategic market segments that UMI is pursuing. AGM’s pipeline of ongoing customer engagements for evaluating its products and technologies will also significantly accelerate UMI’s overall product/market adoption strategies, UMI says.

“The acquisition of AGM fits exceptionally well with UMI’s growth strategy by significantly enhancing our dispersion and application capabilities for advanced paints and coatings. Moreover, it will provide UMI with an important European footprint for strengthening our growth potential,” says John van Leeuwen, CEO of Universal Matter.

Related Content

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

.jpg;width=70;height=70;mode=crop)