Heavy-duty infusion: Scaling up for scrubbers

Infused 3-D woven fabric preforms best steel in beams and unitized deck structures built for the caustic confines of massive flue gas desulfurization systems.

The flue gas desulfurization (FGD) process removes sulfur dioxide (SO2) — one of the elements in acid rain — from fossil fuel power-plant emissions. FGD systems, commonly called scrubbers, encompass a wide variety of designs. Two common types of scrubbers use water filled with limestone reagent, which reacts with SO2 and other harmful elements, to remove them from the power-plant exhaust. These “wet scrubber” processes produce not only emissions that are compliant with Environmental Protection Agency (EPA) regulations but also a resalable gypsum byproduct. However, older scrubber designs feature housings and structures made either from concrete lined with glazed porcelain tile or steel clad in thin sheets of nickel alloy, says Ed Wesson, engineering manager at RPS Composites Alabama Inc. in Mobile, Ala. (formerly Non Metallic Resources). “This cladding is expensive — about $50/lb for nickel alloy steel — and it is troublesome, as it tends to come off of the steel substrate,” he explains. When the cladding peels, corrosion of the underlying steel is immediate, he maintains. “Basically, it is like being in an acid-rain storm, except concentrated inside the scrubber housing.” The concentrations of limestone particles are very high and they move at high speeds, producing a continuous sandblasting effect. The scrubber’s water/limestone reservoirs often are heated (~130°F/~54°C), intensifying an already corrosive environment.

As the prices of nickel-coated steel and nickel-alloy scrubbers continue to rise in the cost-sensitive power industry, Wesson notes that RPS is one of a handful of capable companies, including Augusta Fiberglass (Blackville, S.C.), Ershigs (Bellingham, Wash.), Plasti-Fab (Tualatin, Ore.), Kenway Corp. (Augusta, Maine), RL Industries (Fairfield, Ohio) and Bedford Reinforced Plastics (Bedford, Pa.), that can provide large composite scrubber structures as an economical alternative to conventional metalwork.

RPS operates a 100,000-ft2 (9,290m2) facility where it uses vacuum infusion processing to build a variety of heavy-duty internal structures for wet scrubbers, including 25-ft to 38-ft (7.6m to 11.6m) long beams with 12-inch by 25-inch (0.3m to 0.6m) cross-sections and decks ranging from 14 ft by 21 ft (4.3m by 6.4m) to 15 ft by 60 ft (4.6m by 18.3m). Decks, at 1.4-inch/0.036m nominal thickness, have integrated 16-inch (0.4m) tall ribs along 4-inch/0.1m wide built-in stiffening beams. Notably, these multi-ton fiberglass composite structures are layed up quickly and infused in one shot, the latter often accomplished in less than 10 minutes, depending on beam geometry, thanks to a unique 3-D woven reinforcement that is a key component in a molding process optimized to produce large parts with maximum performance at minimum cost.

Engineering before beginning

Although a typical beam-and-deck project lasts about 14 months from design finalization to end of production, the RPS predesign timeline is even longer. “You have to convince the customers of the concept first,” says Wesson. “Metal is still our biggest competition,” he notes, “and the customer is not going to pay for all of the design work and testing required to show how the same structures in composites perform equally well or better.” Wesson notes that the power-generation industry is very conservative, and both OEM and refit projects have supply chains with many links. For example, one or more power companies could be involved as plant owners and customers, plus a project management firm, an engineering services provider, a construction contractor and others — each with a set of qualifications that must be met.

“If you do get the job,” Wesson relates, “you have to do a lot of engineering work very quickly as well as prove out your manufacturing process. The customer gives RPS its working envelope: the overall scrubber dimensions and the required number of spargers (plastic pipes that direct flue gas into the reagent bath) and risers (larger-diameter fiber-reinforced plastic pipes that duct scrubbed gas up out of the bath). Wesson then sizes the beams to produce the specified stiffness and calculates the beam and deck dimensions from moment-of-inertia formulas modified for anisotropic materials. Mike Rogers, RPS senior designer, develops the structures in SolidWorks 3-D solid modeling software (Dassault Systèmes SolidWorks Corp., Concord, Mass.).

As part of the initial design prove-out process for its heavy-beam infusion process, RPS manufactured two beams and had them tested at North Carolina State University’s Constructed Facilities Laboratory (Raleigh, N.C.) to validate the computer modeling and failure mode. For the latter, the beams were loaded using a four-point bending setup and averaged more than 650,000 lb (294,835 kg) before failure. RPS worked for approximately two years on product and process development before its first product delivery. Now that a process is in place for performance prediction and beam manufacture, delivery is in weeks, not years.

RPS currently manufactures beams for scrubbers developed by Advatech LLC (Franklin, Tenn.), and Chiyoda Corp. (Yokohama, Japan), as well as decks with integrated beams for Chiyoda scrubbers (see the sidebar "Wet scrubber primer" at the end of this article, or click on the title under "Editor's Picks," at top right).

Advatech beam production

The Advatech beams are essentially solid rectangular box beams infused in one shot. Wesson credits infusion speed to the 3-D woven structure of 0.75-inch/20-mm thick UniGirder 3-D woven unidirectional E-glass preforms supplied by 3TEX (Cary, N.C.). In conventional layups, several hundred plies of unidirectional fabric are cut, kitted and then layed up. The uniaxial fibers nest tightly, making it difficult for resin to flow through them. Although flow media help move resin along the bag surface, it is difficult for resin from the bag side of the structure to migrate to and thoroughly wet out the tool side.

The 3-D weaving process, however, aligns UniGirder’s multiple layers of unidirectional E-glass to create vertical “elevator shafts” that enable resin to drop through and spread out at every ply of the fabric, from the bag face to the tool. This enables fast and thorough wetout without sacrificing high fiber volume fraction. “We don’t add more empty space, we use less,” says 3TEX technical product manager Don Wigent. “We simply organize and align all of the spaces to alleviate the traditional problem of trying to shove resin between alternating fiber bundles. The result is a network of infusion flow paths within the fabric architecture, large to small, like arteries.” For example, an internal 3TEX test shows a 751-oz/yd2 (25,464-g/m2) UniGirder preform infused in less than 18 seconds, with every level of the 0.7-inch/18-mm thick stack fully impregnated with resin.

The preforms save the molder many hours of layup time. UniGirder ships as flat slabs in truck-length reusable crates, not on rolls. This enables RPS to lay down the large volume of required reinforcement — 780 oz/yd2 (26,447g/m2) per ply — in just seven plies, with minimal cutting.

Further, the UniGirder preform is already within 10 percent of its final thickness. By contrast, a conventional layup of comparable areal fiber weight involves multiple fabric plies that trap air as they are stacked. For example, the 29 plies of 26-oz/yd2 (882-g/m2) unidirectional E-glass required to match the areal weight of a UniGirder 751-oz/yd2 (25,464-g/m2) preform create a stack twice as thick prior to application of vacuum. The change in thickness that results as the laminate is compacted can cause wrinkling, fiber misalignment and a knockdown in final structural properties, not to mention dimensional tolerance issues. For a 0.5-inch/12.7-mm thick part this can be a problem, but with a 25-inch/635-mm thick part, it can cause structural failures due to a mismatch of mating surfaces as beams and decks are bolted together.

Each Advatech beam is made with as many as seven plies of UniGirder 780 oz/yd2 (26,447g/m2) fabric sandwiched on either side of a composite flow core, which channels resin through the beam’s length. Developed by Eddie Lane (OCV Reinforcements, Toledo, Ohio), André Cocquyt (GRP Guru, Brunswick, Maine) and Wesson, the laminate schedule results in a high-quality structure that is easily infused and achieves more than 60 percent fiber content by weight and a stiffness as high as 7 Msi/48 GPa in the critical flanges (e.g., beam caps).

Beam layup begins by kitting the UniGirder preforms into seven-ply “logs.” The flow core is sandwiched between two logs in a pneumatically actuated fixture that combines these into a complete beam preform. The preform then receives an abrasion-resistant surface layer (prefabricated in-house) and is fastened together with steel bands similar to those used on wooden pallets. An overhead crane transfers the now 4,000-lb/1,814-kg preform to an adjustable-width steel mold, which is cooled and heated with water to control exotherm and cure.

Technicians then lay out vacuum hoses and plug feed lines into the mold. Although infusion is complete in minutes, the beams are left to cure for up to 24 hours. Wesson explains, “I prefer a long, slow cure to avoid residual stresses and also to ensure 100 percent wetout, which is critical for composite structures in such a caustic environment.” Fast infusion is still a distinct benefit, Wesson points out, because the window for infusing the preform is not very wide. The resin needs to flow while temperatures are between 80°F and 100°F (27°C and 38°C). With structures this large, thousands of pounds of resin are infused, and exotherm begins quickly. When the resin reaches 100°F, the resin flow is too slow to wet out the fibers completely. Inadequate wetout could dramatically reduce the structural performance and the corrosion resistance of these structures.

Most of the beams for the Advatech-type scrubbers are infused with a vinyl ester infusion resin from AOC LLC (Collierville, Tenn.) that is specially formulated to meet Wesson’s specified viscosity flow profile. Each demolded beam is tested on an in-house deflection test rig, which can apply up to 40,000 lb/178 kN of force, according to the specification for each type of beam. After passing the deflection test, beams are cleaned up cosmetically and receive a final abrasion-resistant coating.

Manufacturing Chiyoda decks

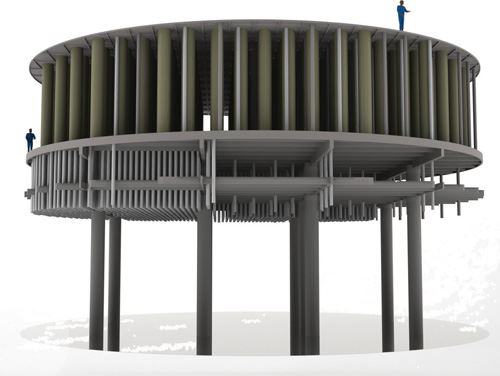

RPS also is building the upper and lower decks for a 95-ft/29m diameter Chiyoda scrubber in pieces that will be assembled on the construction site. A common beam-stiffened deck panel weighs 9,000 lb/4,082 kg and measures 14 ft/4.3m across, 21 ft/6.4m in length, with a 1.4-inch/35.6-mm thick surface that increases in thickness to 16 inches/406 mm along the 4-inch/102-mm wide beams. Deck panels can be as large as 15 ft by 60 ft (4.6m by 18.3m) and also must contain materials and coatings that ensure extreme abrasion resistance.

One of RPS’ key innovations circumvents the traditional approach of mechanically attaching beams to decks, which results in issues during installation and problems with performance during the structures’ 30-plus-year service life. Wesson explains: “Integrating the beams into the deck sections replaces uncontrolled work in the field with controlled, quality production in our shop and also reduces expensive installation time on site.” The result is of great value to RPS customers: less risk and downtime, control over quality, longer life and little threat of structural failure, thanks to the one-piece, seamless construction. The integrated beams are formed from two to four plies of the 780 oz/yd2 UniGirder fabric preform. A conventional layup would require 50 to 100 plies of heavyweight E-glass fabric.

The integrated deck structures begin with several layers of abrasion-resistance-treated chopped strand mat as an outer sacrificial layer that will help to ensure a long service life. Next, three to eight plies of 3TEX 158-oz/yd2 heavyweight unidirectional fabric is kitted for the 1.25-inch/33-mm thick deck laminate, and beams are kitted and preformed as previously described for the Advatech beams. Then, deck laminate reinforcements are placed onto a large, thermally controlled steel table mold, followed by the beam preforms.

While the whole assembly is vacuum bagged and prepared for infusion with vacuum and feed lines, the reinforcements gradually warm to the same temperature as the underlying heated table mold. The resin is preheated to the same temperature prior to infusion. This temperature parity ensures uniform flow during infusion. Cooler regions could increase resin viscosity locally, slowing the flow and, possibly, retarding wetout and/or resulting in residual stresses within the structure. Infusion is completed using vinyl ester infusion resins from Ashland (Columbus, Ohio) and AOC. Infusion of the integrated beam/deck structure takes about one hour. The infused part reaches green cure in 8 to 12 hours. Demolded decks are transferred by overhead crane, using vacuum lifts, to another station, where riser pipe holes are machined, the structure is cleaned up cosmetically and an abrasion-resistant coating is applied.

FRP future in FGD

The EPA maximum achievable control technology standard for the utility industry (Utility MACT), released in March, requires installation of 83 to 100 GW of FGD scrubbers by 2015, according to utility-industry estimates. The EPA asserts that most of the scrubbing capacity could be achieved via cheaper, faster dry scrubber and fabric filter installations, but wet scrubbers are, in fact, more cost-effective for the mercury and hydrochloric acid (HCl) removal mandated by Utility MACT. Notably, the McIlvaine Co. (Northfield, Ill.) predicts in its online FGD: World Markets forecasts that more than 2,000 scrubbers will be installed worldwide by 2023 and that wet scrubbers will account for 80 percent of the total.

Although large FGD contractors have historically assumed that fabrication of the thicker and more performance-intensive sections from composites is not practical, the RPS method demonstrates that recent developments in vinyl ester resins, heavy fiber preforms and infusion processing prove otherwise. These massive composite structures could make a large contribution to the greening of the power utility industry.

Related Content

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)