HPC’s 20th Anniversary: DeWayne Howell looks back

On the occasion of HPC's 20th Anniversary, DeWayne Howell, currently president of Peak Composites Inc. (Arvada, Colo.) looks back to 1993, when composites manufacturing development engineer at StorageTek (Louisville, Colo.) and worked with HPC on the first Inside Manufacturing article in the premiere issue of HPC in September 1993.

In 1993 StorageTek, now Sun Microsystems, was one of the world leaders in data storage using the medium of magnetic tape. Their biggest seller was a data storage library system called Powderhorn, an 8 ft tall by 12 ft diameter (2.4m by 3.7m) circular silo that had thousands of tape storage cartridges lining the inside walls of the library. Each tape resembled one of those old 8-track music cartridges from the 1970s. At that time, the library could store up to 3,600 terabytes (TB) of data. (That’s a lot of storage space, but we can now buy hard drives for our computers that hold 20 TB!)

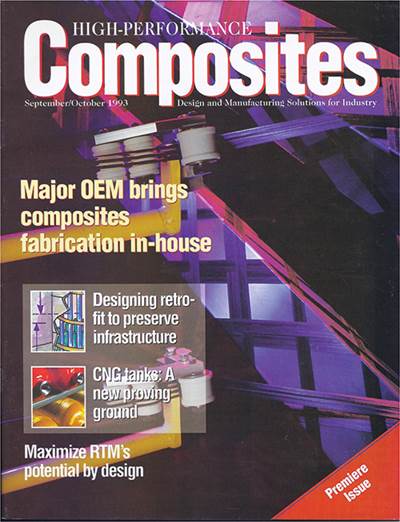

The silo housed a robot in the shape of the letter "H" that spun on a central axis picking and placing the data tapes into tape drives and back again into their storage locations. The robot consisted of two vertical 4-inch (101.6-mm) square cross section box beams and one 7-inch (177.6-mm) square horizontal box beam. We fabricated these robotic arms via the filament winding process using standard modulus carbon fiber/epoxy prepreg tow.

Composites were the best solution because they offered the light weight and high stiffness that enabled the robot to move at rapid speeds while precisely maintaining positional tolerance for the end-effectors that moved along the arms. We were well into the start of production of the arms when HPC came to us asking to feature the parts in the inaugural issue of the magazine. The composite arms made the front cover of the magazine. (I still have about four copies tucked away in my desk for sentimental reasons and as collectors items. Maybe I can sell them in a few years at the next “CompositesCon” and help put my grandkids through college!)

The project originated when an engineer at StorageTek determined that composites were the solution and started looking for a local fabricator. They came to Spaulding Composites in Golden, Colo., for the answer. Within a few months, prototypes were built and tested. StorageTek purchased the assets of Spaulding and hired me, two other engineers and a technician to create an in-house manufacturing group for the fabrication of the arms. This was a huge step for StorageTek. The company knew very little about composites, but was determined to make sure that it captured the ability to produce the arms, as it was a key enabling technology for the Powderhorn library.

Among the many challenges for the project, one was maintaining dimensional control of the outside dimensions (OD) of the box beams. Because we filament wound onto a mandrel, there was no issue with getting a tight tolerance on the inside dimensions (ID) of the beams because it was a tooled surface. The OD, however, conformed to four floating caul sheets that almost touched at the juncture of each corner of the tube. Floating caul sheets meant that there was misalignment and OD variation issues. Through much painful development, we settled on a chamfered edge caul that helped hold the position of the sheet on the face of the composite laminate and minimized fiber pinching, resin bleed and pooling in the corners. We produced a lot of scrap square box beams for a while and the material review board (MRB) room had to be purged. So, we did what anyone else would have done — we built a deck out of the scrap box beams. One of our technicians took home enough of the out-of-spec beams to make an entire deck on the back of her house. I'm certain, to this day, that it is still the only carbon fiber composite deck in the world!

Like most projects, the box beams lead to several other successes. Being a composites manufacturing group inside of an otherwise electronics assembly company, we were a novelty. We exploited this for all that it was worth. I assembled and taught a composites training workshop that was offered to all 5,500 StorageTek employees. The engineers within the company were very quick to take advantage of the training and concurrent plant tours we offered. Several hundred graduates later, we were designing four other composite structures, three of which made it into production on other StorageTek library systems as robotic arms and as the support pedestal for the Powderhorn robot. In addition, our expertise in the fabrication of low-cost, tight-tolerance box beams helped us become a supplier to the motion picture industry making camera booms — very long camera booms. Also, we supplied the automation industry with very thin-walled, rectangular-shaped beams for use as robotic arms.

Today the archaic tape data storage libraries have been replaced by hard drives and solid state storage systems. Advances in electronics have passed us by and such robots are no longer needed. Thus the need for composites has gone away. The Powderhorn library, and its composite robot, continue to operate in some instances, but is more likely to be seen in a museum than in actual use. But, at the time, we had the solution to the robot dilemma — a very good solution. For the cost and performance, nothing else could replace the carbon fiber composite robotic box beams. In fact, this project was one of the most rewarding in my 28-year career in composites. It’s always a joy to come upon an application for composites that is the right application at the right time and get the opportunity to play an influential role in the concept, design, analysis, development and volume production of a true composite solution.

Related Content

Composites UK launches best practice guide for composites tooling

“Mould Tooling for Fibre-Reinforced Polymer Composites” is latest in Composites UK’s series of good practice guides, available online for free.

Read MoreToray, University of Chicago speed up polymer recycling R&D

A jointly developed multi-scale computational predictive technique can accurately predict viscoelasticity from the chemical structures of polymers, ramping up product maturation.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreReducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

Read MoreRead Next

HPC’s 20th Anniversary: The senior technical editor looks back

In celebration of HPC's 20th Anniversary, HPC's senior technical editor Sara Black recalls the early days at HPC and the changes that she's seen.

Read MoreHPC's 20th Anniversary: Not just a magazine, but a mission

On the occasion of HPC's 20th Anniversary, HPC's managing editor Mike Musselman recalls his early days on staff, the things that have changed, and those that haven't.

Read More

.jpg;maxWidth=300;quality=90)