Hydraulic hybrids: Boosting fuel economy without batteries

Carbon fiber helps to lightweight hydraulic accumulators, increasing efficiency in hybrid vehicles and myriad other applications.

UPS has 50 hydraulic hybrid delivery trucks in the Chicago metro area. These vehicles, which use carbon fiber composite wrapped accumulators, offer a significant reduction in fuel usage and CO2 emissions and cut NOx emissions in half.

SOURCE: Lightning Hybrids and Steelhead Composites.

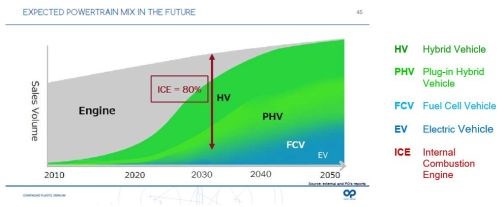

Composites have generally benefitted from the growth in hybrid vehicles, because lightweight materials are used to help offset heavy batteries and extend driving range on a single charge. According to Plastic Omnium’s (Île-de-France, France) Dec 2016 Investor Day presentation, all vehicles will be some type of hybrid by 2050.

SOURCE: Plastic Omnium,

Investor Day Strategy and Innovation, Dec 2016.

A vehicle is a hybrid if it uses two or more power sources to achieve propulsion. Typically, the primary power comes from fossil fuel — gasoline or diesel — with supplemental power coming from batteries and/or energy recaptured during braking (regenerative braking) using a generator and electric motor. This reduces the power demand on the engine, which in turn lowers fuel consumption and emissions.

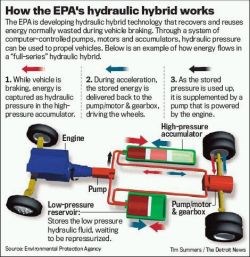

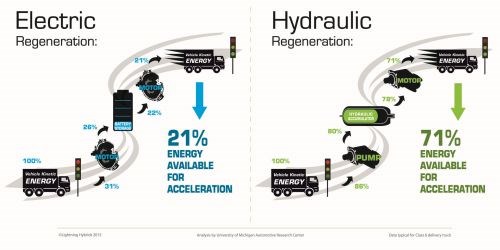

However, a hybrid vehicle does not necessarily have to involve batteries or electrification. According to the US Environmental Protection Agency (EPA, Washington, DC) and Lightning Hybrids (Loveland, CO, US), hydraulic hybrids are more efficient and easier to implement, especially for heavier vehicles.

Hydraulic hybrids use many of the same principles as electric hybrid vehicles, but instead of batteries, they use a lightweight hydraulic system to capture and reuse braking energy for powering the vehicle at slow speeds. The EPA has been experimenting with hydraulic hybrids since the late 1980s. Today, companies such as UPS, DHL, Kiessling Transit, Denali National Park, Hyatt Hotels, Miami Dade County, and many others are running hydraulic-hybrid systems from Lightning Hybrids and Parker Hannifin (Cleveland, OH, US).

|

|

Hydraulic hybrid systems are efficient, compact and affordable, reusing braking energy to provide power for acceleration, which reduces vehicle fuel use and emissions. SOURCE: Lightning Hybrids (left) and EPA (right).

How Hydraulic Hybrids Work

Hydraulic fluid is stored in a low-pressure reservoir (aluminum tank with bladder). A pump moves the fluid from the reservoir to a high-pressure accumulator (composite tank with bladder). The accumulator holds not only the fluid brought over by the pump, but also pressurized nitrogen gas in the bladder.

During regenerative braking, kinetic energy from the vehicle’s motion powers the pump via the drive shaft, moving fluid from the reservoir to the accumulator. This slows the vehicle down, which means the hybrid system acts as the primary braking system. During this phase, pressure builds in the accumulator due to the nitrogen gas being compressed, and this acts as a mechanical battery, storing energy to be released when the vehicle needs to accelerate again. As the vehicle accelerates, the accumulator sends its energy, in the form of pressurized hydraulic fluid, to the pump, which now acts as a motor, turning the vehicle’s driveshaft and thereby reducing the load on the engine. This is how fuel use and emissions are reduced. (Note, in an electric hybrid vehicle the regenerative braking energy is transferred first to an electric motor which then turns the driveshaft.) As the vehicle accelerates, the hydraulic fluid returns to the reservoir, ready to charge the accumulator again during the next braking event.

The process is very simple and efficient. According to a Sep 2016 article by Lightning Hybrids CEO Tim Reeser, customers running hydraulic hybrid vehicles report a significant reduction in fuel usage and CO2 emissions. NOx emissions are also reportedly cut by 50%. Other benefits of hydraulic hybrid technology include:

- Does not require as much space or payload sacrifice as battery hybrids;

- Much less expensive than electric hybrid drivetrains;

- Reduces engine exhaust during acceleration;

- Adds power/torque allowing for engine downsizing (typically 600-800 lb-ft for UPS van);

- >100% improvement in brake component life.

Conventional batteries (and even flywheels) lack the high specific power density of lightweight composite accumulators that enables efficient storage and reuse of regenerative braking energy in heavy vehicles.

SOURCE: Steelhead Composites, plot courtesy of W. J. B. Midgley and D. Cebon, “Comparison of Regenerative Braking Technologies for Heavy Goods Vehicles in Urban Environments,” Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, vol. 226, pp. 957-970.

United Parcel Service (UPS, Atlanta, GA, US) has 50 Lightning Hybrids hydraulic hybrid delivery trucks in the Chicago metro area. Sold through a network of dealers and upfitters, the Lightning Hybrids system is reportedly easy to install, fitting between the frame rails towards the center of the vehicle. With federal and state clean-air- and alternative-energy grants, pricing can be reduce to as little as $5000 for qualifying applicants. UPS’ new Chicago fleet was partially funded by Drive Clean Chicago — a program that aims to accelerate the adoption of alternative fuel vehicles and infrastructure in Chicago — and the company anticipates a return on investment (ROI) of 1-2 years.

Lightning Hybrids’ modular Energy Recovery System is easily installed on a wide range of vehicle models. |

Lightning Hybrids developed a thin steel/aluminum liner overwrapped with carbon fiber composite to withstand high pressure at low weight. |

SOURCE: Lightning Hybrids and Steelhead Composites.

Carbon Fiber Composite Accumulators

Lightning Hydraulic Hybrid systems typically add 700-1200 lb (317-544 kg) to the subject vehicle. According to the company’s Mechanical Batteries blog, the composite high-pressure accumulator is a key part of the system’s high performance at low weight.

In its first project, the company found that even small hydraulic accumulators on the market were too heavy, made of thick steel. So it designed a lightweight composite accumulator (Type 3 pressure vessel) made of a thin aluminum vessel (liner) wrapped with carbon fiber composite.

In October 2012, Lightning Hybrids sold the composite accumulator part of its business to Steelhead Composites (Golden, CO, US). This spin-off allowed the company to focus on growing the hydraulic hybrids market while having a close partner to develop and supply accumulators. Steelhead has grown along with Lightning Hybrids and has increased its product line to include other pressure vessels such as compressed natural gas (CNG) and hydrogen tanks, as well as customized diaphragm, bladder and piston accumulators.

But accumulators aren’t just used as pressure vessels for hybrid vehicles. They are key components in myriad hydraulic system applications:

- Mobile equipment — hydraulics enable combines and harvesters, lifters and front-end loaders, bulldozers and dock equipment to do their work. Caterpillar is using hydraulic accumulators to store and reuse energy in its line of hybrid excavators.

Wind turbines — hydraulics power the blade pitch control systems for turbines >3 MW. - Marine — hydraulics control the rudders and roll stabilization in ships and yachts, and are used for loading and launching naval weapons systems as well as to control the pitch of foils and twist of wing masts on racing catamarans and sailing yachts.

- Oil and Gas — hydraulic accumulators balance offshore oil rigs (motion compensation system to resist 40-ft waves) and supply the power for the blowout preventers (BOP) installed in oil wells.

- Industrial — accumulators power pumps and open and close valves in myriad water and fluid delivery and processing systems. They are also used as pulsation dampeners to regulate pressure and flow in a fluid circuit.

- Robotics — hydraulics power the “muscles” in robots, including large systems that lift and position heavy equipment (e.g., nuclear reactors) for installation.

|

|

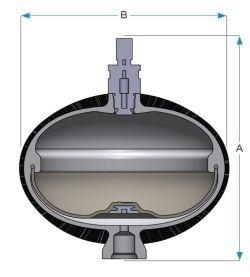

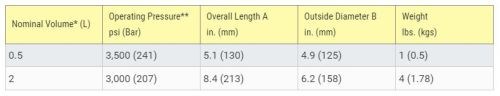

MicroForce Diaphragm Accumulators

SOURCE: Steelhead Composites.

“Accumulators are one of the most ubiquitous components in hydraulics yet little is known about them,” says Mateo Cantu, business development for Steelhead Composites. The company’s patented composite accumulators cut weight 66-75% vs. steel accumulators while offering higher capacity — 30 gal (113 L) with pressure rating of 6000 psi (414 bar) — versus steel, which caps out at 15 gal (54 L).

“Steel accumulators have been used for decades, but we’re the first company to offer off-the-shelf composite accumulators for hydraulic hybrids to improve performance.” He points out the company’s name, noting it is also one of their proprietary advantages, “We designed a steel port or 'head' into our composite accumulators which allows high flow rates and also a wide opening for bladder maintenance, but without a weight penalty or performance limit compared to steel accumulators.”

Cantu sees a lot of opportunity, not only in rapidly-developing applications for robotics and high-performance vehicles, but also in the customization Steelhead Composites offers. “We spin-form our own metal and complete composite winding in-house, so we can create custom sizes.” For example, the MicroForce family of diaphragm accumulators are Type 3 composite pressure vessels that measure roughly 5-6 inches (125-158mm) in diameter. Capable of 3,000+ psi (207 bar), they are available in 0.5 and 2.0 liter internal volumes, weighing 0.5 and 1.78 kg, respectively. “As accumulators move into this world of smaller hydraulic devices, our ability to develop tailored solutions is a real enabler for our customers.”

Related Content

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreDrag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

Read MoreHonda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

Read MoreCollins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)