IBEX 2009 Marine Composites Showcase

The 19th International BoatBuilders’ Exhibition & Conference endures the economic “perfect storm” on the Florida coast and looks forward to fairer weather inland.

Although attendance at the 19th International BoatBuilders’ Exhibition & Conference was down 31 percent in Miami Beach, Fla. this year, compared to last year, IBEX 2009 organizers — the National Marine Manufacturers Assn. (NMMA) and Professional BoatBuilder magazine — reported that international participation was up: Visitors from 65 countries attended the event, Oct. 12-14, with the largest non-U.S. numbers from Canada, Australia, Colombia, Brazil, United Kingdom, Norway, Venezuela, Netherlands, New Zealand and Nigeria.

IBEX officials took their show theme “Rethink Everything” seriously, announcing that in 2010, the event would desert its familiar Florida moorings to dock in at the Kentucky Convention Center in Louisville, Ky., Sept. 28-30. “Given recent changes in today’s economy and the boating industry, we felt show exhibitors and attendees would benefit from the move to a more central location that will help lower their costs to participate,” explained Thom Dammrich, NMMA president, noting that the 6th largest U.S. convention facility was selected, in part, because food, beverage and hotel costs will be lower for participants by more than 20 percent.

Composites industry suppliers who serve the boatbuilding industry gathered, once again, at the IBEX Composites Pavilion, marketing an array of technologies designed not only for marine applications, but for other composites applications as well. CT was on hand, and found the following noteworthy sampling.

Peel ply for wind blade manufacturing

Airtech International Inc. (Huntington Beach, Calif.) introduced its new Econostitch 5445 tight-weave peel ply, featuring 30 percent more material, which increases its strength and reduces the amount of resin on the surface, making it much easier to remove. Also new were Econostitch 66 and Econostitch G peel plies. The former, developed specifically for wind turbine blades manufacturing, is for customers who prefer a peel ply made with Nylon 6.6. The latter is a polyester peel ply with black tracers, economically priced for marine, wind energy and other commercial applications. Both products are scoured to ensure no contamination, which could degrade secondary bonding, and both are heat-set to eliminate shrinkage and corresponding peel-ply removal issues.

Sound-damping PU foam

Alcan Composites (Sins, Switzerland) showed off its AIREX PX line of fiberglass-reinforced, low-density polyurethane foam, and its newest-version Acoustiboard (see second photo at right), targeted to boat engine rooms, sound studios and other applications that require sound damping. Although these materials have been out since 2007, the combination of various PX materials is new, as is Alcan’s working relationship with Bongiovi Acoustics (Port St. Lucie, Fla.) to develop a variety of new building and construction applications. Alcan also has expanded its polyethylene terephthalate (PET) foam core line with AIREX T92, a stiffer, stronger product than its first-generation T91 PET core. Said to offer better damage tolerance than polyvinyl chloride (PVC) foam, the new core offers complete recyclability and thermoformability at a cost lower than that of the PVC core.

Flexible, weatherable gel coat

Ashland LLC (Dublin, Ohio) introduced its new MAXGUARD NRX high-flexibility/high-weatherability marine white gel coat and MAXGUARD NRP ultra-weatherability marine white gel coat. MAXGUARD NRP is said to improves weatherability by 60 percent over standard marine white gel coats and is targeted to big boats that sit under the harsh sun year round. MAXGUARD NRX is built from the NRP base technology so that it weathers well but also improves flexibility in small boats by 36 percent in the mandrel bend test. Both new product lines reportedly are easy to apply and repair and are already in commercial use.

Closed molding education

Composites One (Arlington Heights, Ill.) showcased its Closed Mold Alliance, a consortium of Composites One and three of its suppliers — Magnum Venus Products (Clearwater, Fla., equipment: RTM North Ltd. (Vonastra, Ontario, Canada), tooling/LRTM expertise; and FormaShape (Kelowna, B.C., Canada), tooling supplier, using LRTM— aimed at providing a complete turnkey solution for companies wanting to transition their operations away from open molding to closed molding processes. The Closed Mold Alliance, with over 20 years combined experience in closed molding technology, can work with companies to develop a roadmap for making this change, outlining materials, equipment and training needs. Composites One also offers education through its Closed Mold University. Its first session in 2010 — CM302 Advanced Light RTM Tooling — is scheduled for April 26-30 in Kansas City, Mo.

Glass fiber for wind & marine

Gibson Fiberglass (Irwindale, Calif.) was the only fiberglass supplier present at this year’s show and is the North American distributor for Jushi Group Ltd. (Tongxiang City, Zhejiang Province, China), which claims it is the largest fiberglass supplier worldwide. New was E6 glass fiber, which reportedly has 15 percent higher strength than E-glass, a softening temperature 60°C/108°F higher than E-glass, and better corrosion resistance.

Reinforcement/core kitting program

High Modulus (Auckland, New Zealand) introduced its new U.S. sales office, in Gloucester, Mass., headed by general manager James Anderson, a High Modulus senior engineer and finite element analysis (FEA) specialist. The company also presented its B3 SmartPac construction solution, which optimizes laminate design and kitted materials, including pre-cut and labeled reinforcements and core materials. The system can be used for hulls, decks, superstructures, internal structures, or any other boat component, as well as nonmarine composite structures, and offers additional benefits such as reduced material costs, minimized waste, reduced in-mold time and improved quality control.

MMAs with long open times

Plexus (Danvers, Mass.) introduced MA 2045 and MA 2090 methacrylate adhesives, with open times of 45 and 90 minutes, respectively, for adhesive bonding of large structures. With a 10:1 mix ratio, the adhesives have the unique ability to bond via thin bondlines (e.g., boat deck) or thick bondlines (e.g., stringers). The product is suitable for use in large nonmarine structures as well, as demonstrated by customer DesignLine (Charlotte, N.C.), which uses Plexus adhesives to assemble their all-composite, environmentally friendly electric bus, currently in-service in several airports across the country.

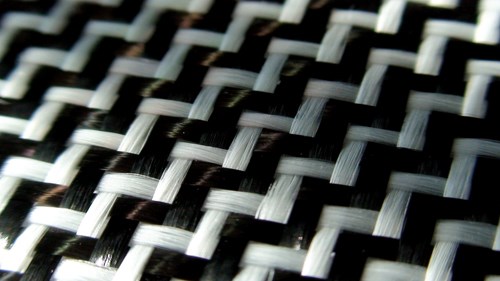

HMPP fiber fabricsJ B Martin Ltd. (Quebec, Canada) and North American Composites (NAC, Lino Lakes, Minn.) showed their new Innegra-brand high-modulus polypropylene (HMPP) fiber fabrics (an example is shown in the third photo, at right), targeted for a wide variety of composites applications. Five different noncrimp weave styles are available (custom fabrics are possible with sufficient volume) with varying percentages of HMPP, carbon and aramid fibers, including a 100 percent Innegra fabric, depending on the properties required for the customer’s application. Innegra fiber was developed and is produced by Innegrity LLC (Simpsonville, S.C.).

Epoxy tooling paste

Pro-Set Inc. (Bay City, Mich.) introduced M-1019 epoxy with M2010 hardener as a high-temperature epoxy tooling paste, developed to produce a buffable epoxy mold surface and provide good thermal stability up to 250°F/121°C service temperatures (without metallic fillers) for companies looking at fabricating heated molds or molds for post-curing. Also highlighted was PRO-SET 195/295 Tooling Paste. The high-density system, with no porosity or low-density fillers (problematic in machining), provides a hard surface capable of razor-sharp edges.

Modeling software & plug-ins

Three-dimensional (3-D) modeling software supplier

(Seattle, Wash.) shared exhibit space with new marine design plug-in suppliers

T-Splines Inc.

(Stevensville, Md.) and

T-Splines Inc.

(Provo, Utah) to offer a more powerful computer-aided design (CAD) program, specialized for marine applications. According to the company, software programs based on triangular mesh frames are inadequate for manufacturing purposes. Rhino’s latest 3-D modeling software with Orca3D and T-Splines plug-ins generates very smooth, accurate model surfaces and reportedly can be used throughout the design and production processes, including tooling and prototyping phases. (Rhino 3D software is featured in thsi issue's “Applications” article. Click the link under "Editor's Picks," at right).

Related Content

IPSA acquires bonding adhesives based on MMA technology

IPS Adhesives (IPSA) introduces a line of adhesives using acrylate and MMA technology from L&L Products for the bonding of dissimilar materials such as metals and composites.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MorePro-Set named official materials supplier for New York Yacht Club American Magic

Competitive sailing team prepares for the 37th America’s Cup beginning in August 2024 with adhesives, resins and laminate testing services for its AC75 monohull construction.

Read MoreBelzona composite wrap restores corroded carbon steel pipeline

Two-part epoxy paste, epoxy structural adhesive, composite wrap and anti-corrosion coating prevent environmental and economic loss for customer.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)