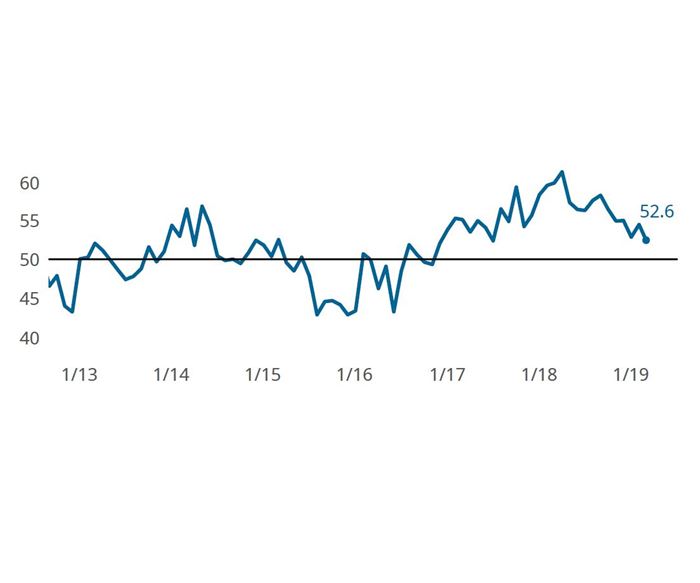

Index shows modest expansion on production and supplier delivery activity

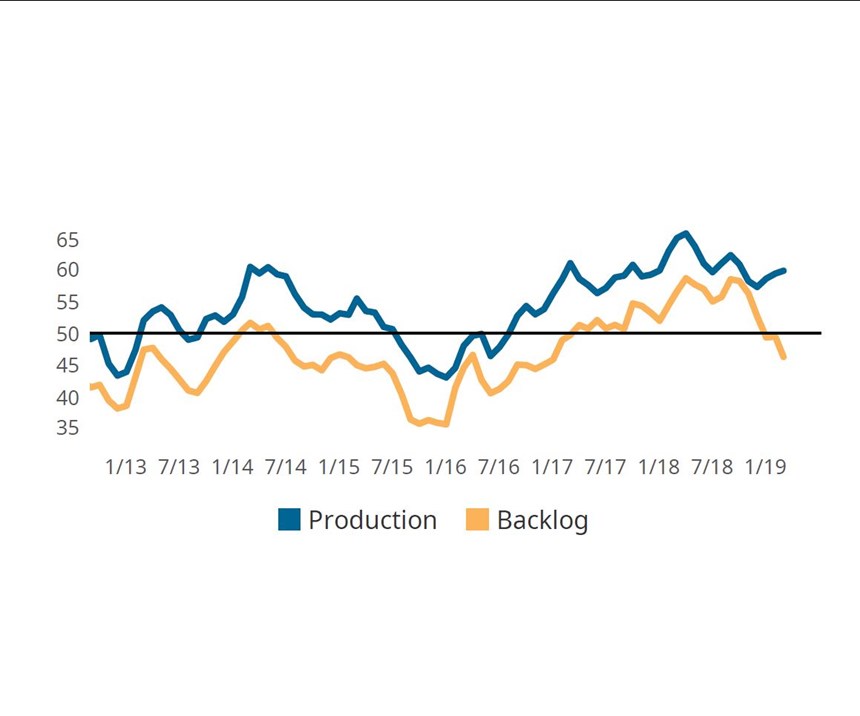

The Composites Business Index moved lower in March as backlogs contracted, resulting from slowing of the previous month’s new orders growth and increased production activity.

Share

Read Next

The March GBI: Composites Index moved lower as a significant slowing of new orders activity combined with an increase in production activity resulted in the sharpest contraction in backlogs since June 2016. The latest reading of 52.6 is 13.0 percent lower compared to the same month one year ago when the Composites Index was only one month away from reaching its all-time high in April 2018. Gardner Intelligence’s review of the underlying data indicates that the Index was sustained by production, supplier deliveries, employment and new orders. The Index – calculated as an average — was pulled lower by exports and backlogs, both of which contracted during the month.

February’s surprise expansion in new orders activity did not carry into March, as the latest reading for new orders fell nearly five points. Between January and March, the new orders reading experienced a net 2.5-point increase. Exports registered a fourth month of either contracting or flat activity, which further weakened order activity. The recent activity in new orders and exports combined with a small increase in production activity resulted in backlogs contracting at the steepest rate in more than two years.

Related Content

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

.jpg;width=70;height=70;mode=crop)