Materials Genome Initiative: Impact on Composites

Promising outlook offered by hands-on source.

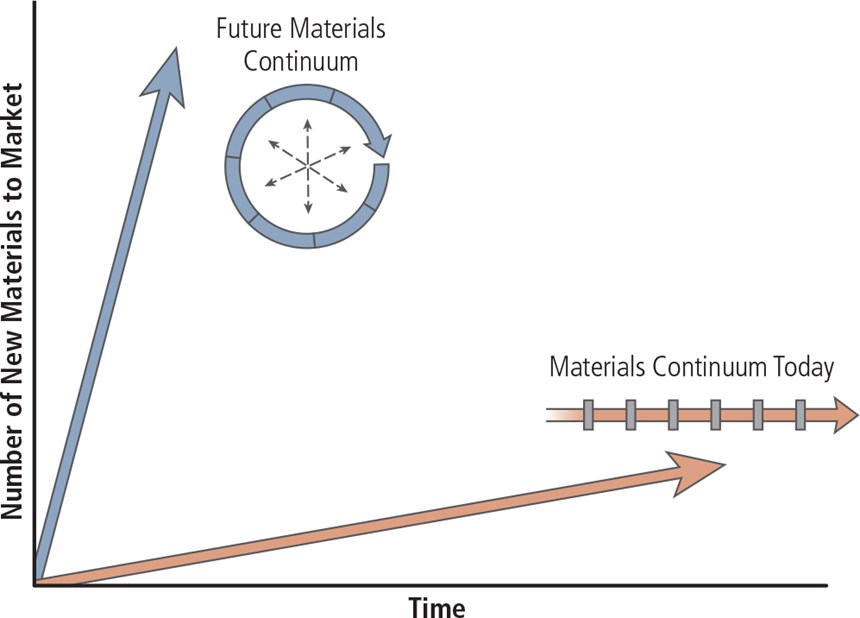

Progress is underway for the Materials Genome Initiative (MGI). This public/private endeavor, launched by the Obama Administration in mid-2011, committed the federal government to work with industry and academic partners to double the pace of advanced materials development. Program goals include vehicles that are safer and more fuel efficient; packaging that keeps food fresher and preserves nutrition; armored vests that better protect soldiers; and metals that can tolerate extreme temperatures and radiation in spacecraft and satellites.

Overseen by the White House Office of Science and Technology Policy (OSTP), the MGI aims to coordinate federal materials science research across multiple agencies and encourage private-sector and academic researchers to develop and share basic materials science discovery data to speed innovation, much like geneticists accelerated the Human Genome Project by openly sharing basic DNA sequence data. CT asked Cyrus Wadia, OSTP’s assistant director for clean energy and materials R&D, to weigh in on the endeavor’s current and future relationship with the composites industry.

CT: How does the MGI program interact with the composites manufacturing industry?

CW: MGI is a multi-agency effort that supports all industrial sectors involved with advanced materials systems, ranging from electronic materials to lightweight composites. As a materials class, the composites manufacturing industry has already played an instrumental role in shaping the MGI. For example, early in the genesis of the MGI, the OSTP had direct engagements with over 12 materials professional societies including, SAMPE [The Society for the Advancement of Material and Process Engineering (Covina, Calif.)] TMS [The Minerals, Metals & Materials Society (Warrendale, Pa.)], MRS [The Minerals Research Society (also in Warrendale)] and ACerS [The American Ceramic Society (Westerville, Ohio)], all of which represent members in the composites field. Furthermore, in the first two fiscal years of the MGI, the federal government has made more than 70 R&D grants across the Departments of Defense and Energy, the National Science Foundation [NSF] the National Institute of Standards and Technology [NIST] and the National Aeronautics and Space Admin. [NASA], including a number that involve the ceramics sector. A good example is the five-year, $10 million effort launched last year by the Air Force Research Laboratory’s Materials and Manufacturing Directorate on advanced polymer matrix composites (PMCs) for aerospace systems.

CT: What impact is the MGI expected to have specifically on the composites manufacturing industry?

CW: To appreciate the significant impact that the MGI can have, consider that the full potential of applying advanced PMCs to aerospace systems is limited today by the lack of integrated simulation tools that capture enough detail to adequately represent the complexity of these high-performance materials in systems design. As noted above, the Air Force Research Lab is leading an industry/academia/government laboratory collaboration that involves General Electric, Lockheed Martin, Autodesk, Convergent Materials, the University of Dayton Research Institute and the University of Michigan to provide the aerospace industry with the integrated engineering tools needed to account for this material’s [PMC] complexity across different spatial and temporal domains.

For example, industry currently lacks an ability to link the chemistry of PMC processing with mechanical performance, particularly the load response and damage evolution for high-temperature PMCs. Therefore, the current design process relies on incrementally building confidence in composite performance for a specific application by repetitive analysis and testing, resulting in component designs that are overly conservative or inadequate for areas where the structure is complex. These tools will be used for design of an airframe wingbox and an engine bypass duct to demonstrate reduced cost, time and risk for the insertion of these materials into use. In addition, reduced conservatism in designs and accelerated transition of next-generation materials will enable performance improvements, resulting in significant fuel savings for both military and commercial aircraft.

CT: What is likely to happen to MGI at the end of President Obama’s Administration?

CW: MGI is not just a federal initiative — it is a growing movement both inside and outside of the federal government. From the government perspective, the MGI now includes active engagement by five federal agencies which are participating in two ways: Individually through their mission-related activities (including funding programs such as the NSF’s “Designing Materials to Revolutionize and Engineer Our Future”) and focused investments such as the NIST’s upcoming Center of Excellence in Advanced Materials, and also in a coordinated fashion through the Subcommittee on the Materials Genome Initiative of the National Science and Technology Council — a cabinet-level interagency coordinating body overseen by the White House. At the same time, the private sector — both industry and academia — has made great strides in adopting and internalizing MGI’s goals and approaches to innovations, with a growing number of university departments and research institutions committing to advance the principles behind this initiative.

At the two-year anniversary of MGI this past June, OSTP announced a number of new private sector commitments and the addition of seven more academic institutions embarking on new educational efforts around MGI goals that include curricula development, new graduate degrees and research opportunities. These recent announcements [see “New commitments to MGI,” p. 20], in addition to those made more than a year ago, demonstrate the long-term commitment the materials research community has made toward achieving the goals of MGI — a commitment we expect will continue well beyond the current administration.

For further information about the Materials Genome Initiative, visit www.whitehouse.gov/mgi. Those interested in getting involved in the initiative can send an e-mail to mgi@ostp.com.

Related Content

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)