New energy storage material for electric vehicles

Penn State researchers have developed sandwich-structured polymer nanocomposites for electric and hybrid vehicle use.

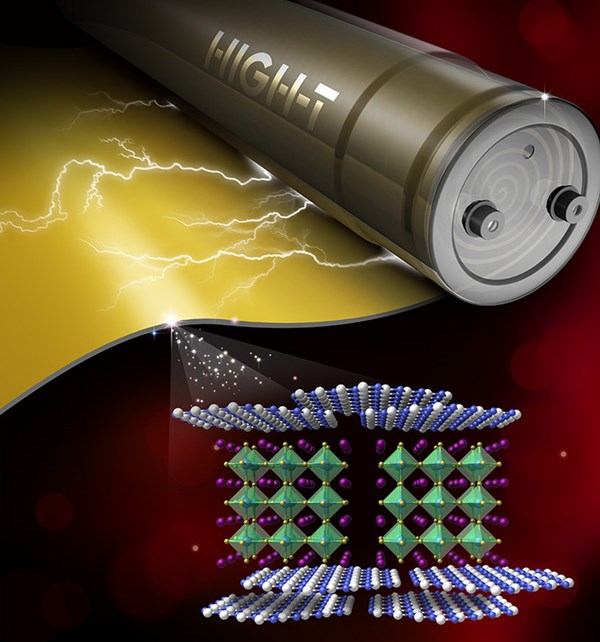

A team of Penn State material scientists have developed an energy-storage material for electric and hybrid vehicle use, according to a news release from the university. The scientists say that the key is a "unique" three-dimensional sandwich-like structure that protects the dense electric field in the polymer/ceramic composite from dielectric breakdown. Their results are published in the Proceedings of the National Academy of Sciences (PNAS).

“Polymers are ideal for energy storage for transportation due to their light weight, scalability and high dielectric strength,” says Qing Wang, professor of materials science and engineering and the team leader. “However, the existing commercial polymer used in hybrid and electric vehicles, called BOPP, cannot stand up to the high operating temperatures without considerable additional cooling equipment. This adds to the weight and expense of the vehicles.”

The researchers had to overcome two problems to achieve their goal. In normal two-dimensional polymer films such as BOPP, increasing the dielectric constant, the strength of the electric field, is in conflict with stability and charge-discharge efficiency. The stronger the field, the more likely a material is to leak energy in the form of heat. The Penn State researchers originally addressed this problem by mixing different materials while trying to balance competing properties in a two-dimensional form. While this increased the energy capacity, they found that the film broke down at high temperatures when electrons escaped the electrodes and were injected into the polymer, which caused an electric current to form.

“That’s why we developed this sandwich structure,” Wang says. “We have the top and bottom layers that block charge injection from the electrodes. Then in the central layer we can put all of the high dielectric constant ceramic/polymer filler material that improves the energy and power density.”

The outer layers, composed of boron nitride nanosheets in a polymer matrix, are reportedly "excellent insulators," while the central layer is a high dielectric constant material called barium titanate.

“We show that we can operate this material at high temperature for 24 hours straight over more than 30,000 cycles and it shows no degradation,” Wang says.

A comparison of BOPP and the sandwich structure nanocomposite, termed SSN-x, in which the x refers to the percentage of barium titanate nanocomposites in the central layer, shows that at 150 degrees C, SSN-x has essentially the same charge-discharge energy as BOPP at it typical operating temperature of 70 degrees C. SSN-x reportely has several times the energy density of BOPP, which makes SSN-x suited for electric vehicle and aerospace applications as an energy storage device due to the ability to reduce the size and weight of the electronics significantly while improving system performance and stability.

“Our next step is to work with a company or with more resources to do processability studies to see if the material can be produced at a larger scale at a reasonable cost,” Wang says. “We have demonstrated the materials performance in the lab. We are developing a number of state-of-the-art materials working with our theory colleague Long-Qing Chen in our department. Because we are dealing with a three-dimensional space, it is not just selecting the materials, but how we organize the multiple nanosized materials in specific locations. Theory helps us design materials in a rational fashion.”

This work was supported by the US Office of Naval Research.

Boron nitride nanosheets (blue and white atoms) act as insulators to protect a barium nitrate central layer (green and purple atoms) for high temperature energy storage. Photo credit: Wang Lab/Penn State.

Related Content

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More