Optimization software improves small, low-cost satellite design

Ames Research Center’s (Moffett Field, Calif.) designs and builds a low-cost, small spacecraft on a quick turnaround, using a modular strategy based on commercial off-the-shelf (COTS) parts and with the aid of several design software packages and finite element solvers.

Several years ago, Ames Research Center’s (Moffett Field, Calif.) director Pete Worden had an idea: design and build low-cost, small spacecraft on a quick turnaround, using a modular strategy based on commercial off-the-shelf (COTS) parts. He envisioned nimble space missions, with design-to-launch in less than two years for as little as $50 million (USD) — one-tenth the cost of a conventional unmanned mission.

Ian Fernandez was on the concept team that was asked to turn Worden’s vision-setting program into reality. “When we started, the vehicle was going to be a lightweight lander,” he recalls. “After many conceptual models, eventually we arrived at the current, fully engineered modular design, or Common Bus.” Its modular design made it possible to rapidly assemble a variety of vehicles from off-the-shelf parts. “We chose composites,” says Fernandez, “because of their high specific stiffness, high strength, low weight and low thermal distortion.”

The Ames Common Bus took its first flight-program shape in 2008 as the Lunar Atmosphere Dust Environment Explorer, or LADEE. This small spacecraft — scheduled for launch this year into a low orbit around the moon — will analyze lunar atmospheric dust. To design LADEE using the Common Bus approach, engineers employed several design software packages and finite element solvers, including ProEngineer CAD with Windchill, MINX and ProMechanica, supplied by PTC (Needham, Mass.); and MSC Patran for the master finite element model (FEM) and NASTRAN as the workhorse finite element analysis (FEA) solver, both from MSC Software (Santa Ana, Calif.). Fernandez added HyperSizer - Collier Research Corporation, a structural sizing and optimization package for composites and metals, from Collier Research Corp. (Newport News, Va.). “HyperSizer is a robust analysis tool that interfaces and iterates seamlessly with NASTRAN,” he says.

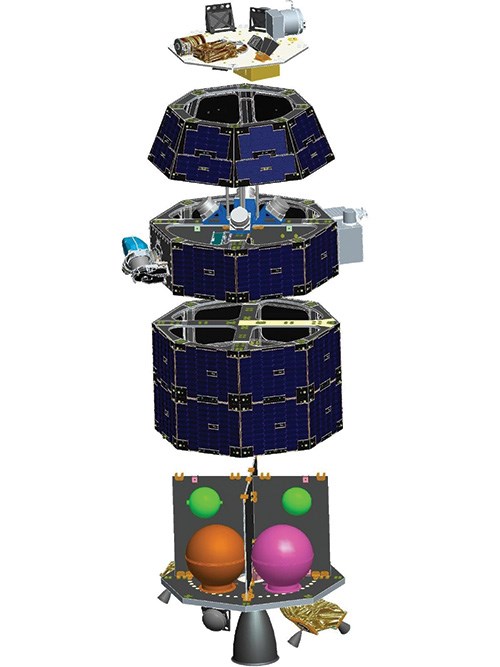

Each Common Bus module is octagonal in shape, approximately 14 inches tall by 46 inches across (356 mm by 1,168 mm) and comprises two facesheets and a honeycomb core. Common bolt patterns on the top and bottom of the structures permit stacking and interchanging them, like LEGOs. For the LADEE project vehicle, four modules would be stacked. The two bottom modules would support the propulsion system, and the two top modules would house instruments. Solar panels would be mounted around the module sides. But design modifications were necessary to customize the vehicle, including trimming away decks and walls to make room for internal equipment and adding inserts to provide equipment attachment points.

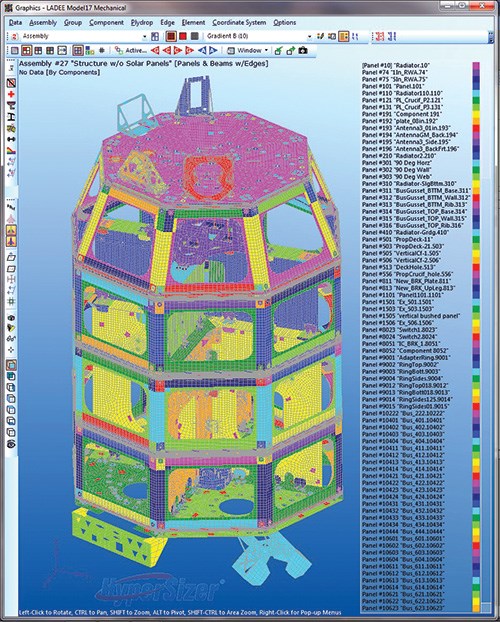

Early in the design process, engineers employed HyperSizer to rapidly perform numerous trade studies, using the software’s extensive material property database to optimize the materials and the module modifications. When the team arrived at a working design, the fidelity of the FEM was sharpened by using HyperSizer to calculate detailed element-by-element margins of safety for each of the many applicable failure modes — for LADEE, approximately 500,000 shell elements were subjected to nearly 100 global load cases. On average, 20 failure modes, including core shear, flatwise tension, face dimpling, local buckling and interactions, were checked for each element, depending on type. Then HyperSizer verified the performance of the composite structures and the metal interfaces and brackets.

“In a full run, the software calculated and sifted through about 1 billion margins for the model,” says Fernandez. “HyperSizer was critically important to organize and present this staggering amount of data.” A simplified manual analysis, he adds, would have resulted in an overweight design, counter to strength and weight goals.

During Critical Design Review, for instance, Hypersizer enabled graphical outputs that illustrated structural margins, critical load cases and critical failure modes. From these, Fernandez could verify and record several element properties, ranging from input loads to material and construction types. The software generated a stress report that became part of the final Primary Structure Stress Substantiation Report. And during fabrication, HyperSizer helped the team resolve nonconformance issues by allowing engineers to quickly assess the impacts of fabrication imperfections, based on margins in those areas.

The spacecraft’s prepreg is T300 and M55J carbon fibers in a TTenCate Advanced Composites (Morgan Hill, Calif.) RS-3C resin. M55J is used only where stiffness is needed to maintain first-mode frequency requirements. All panels incorporate an aluminum honeycomb core, with an aluminum-faced panel for the heat-rejecting radiator, plus hard points for interfaces, brackets for mounting components, and connection fittings for panel-to-panel joinery.

When it is assembled, LADEE’s empty four-module skeleton weighs only 102 lb/46.3 kg. Of that, 70 percent is composite-faced panels, 5 percent is aluminum-faced panels and 25 percent is a combination of metal inserts, fittings and brackets. After the scientific payload is integrated, the craft still weighs only 286 lb/129.7 kg — light for a satellite. At launch, fully equipped, with fuel on board, it will be about 800 lb/362.8 kg, wet mass.

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreThe basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)